When it comes to a vibratory hopper feeder and end-user requirements, The Cleveland Vibrator Company has worked with customers that span the range from simply wanting to increase material flow from point A to point B to more precise applications sending bulk material to downstream processes.

Customer Example

For example, we had the opportunity to visit a local customer and assist him with setting up a hopper feeder unit. Their goal was to place a dry material into plastic trays while they moved on a conveyor under the feeder. Precise metering of the dry material into the trays is critical to this customer’s success.

It seemed this would be an excellent opportunity to discuss material flow and the impacting parameters. As mentioned, the equipment provided by The Cleveland Vibrator Company is a vibrator hopper feeder. The hopper is a stationary non-vibrating hopper with an adjustable slide gate. The vibratory feeder utilizes two rotary electric vibrators. A variable frequency drive (VFD) with a dynamic brake resistor controls the vibrators.

To achieve a precisely controlled material flow, we have to start with the material itself. The material must be consistent in particle size and density, dry and free-flowing. Suppose the material doesn’t flow freely or varies significantly from batch to batch. In that case, it will be challenging to get good repeatable results, even with a fine-tuned system. This is due to the simple fact that the material itself is not consistent.

What do we need to consider?

If we start looking at the parameters and control of the flow off the end of the vibratory hopper feeder, critical factors would include the following:

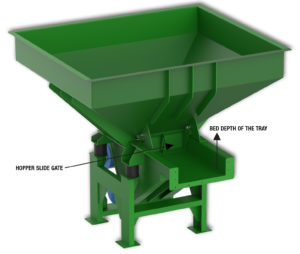

- Bed depth of material on the vibratory feeder tray

- Frequency of the vibration applied to the feeder tray

- Amplitude of vibration or stroke generated by the feeder itself

Each factor has its limitations to influence the flow of material. It is possible to vary the flow rate and provide repeatable results when all factors are combined.

Bed depth of material on the tray

Bed depth of material on the tray

As mentioned earlier, it is important that the material is free-flowing and that there is always material available in the hopper to charge the feeder. Inconsistency of the material will change the depth of material flowing on the feeder. Not enough material will “starve” the feeder and reduce the bed depth. Fluctuations in the volume of material available in the hopper will cause the material bed depth to rise and fall during the operation of the equipment. For consistent discharge rates, we need a consistent bed depth of material.

Opening the hopper slide gate will increase the material moved down the feeder tray. This results in a deeper flow of material and typically higher volume off the end of the feeder. Likewise, reducing the opening restricts the volume of flow out of the hopper, all things being equal; lowering the gate will reduce the bed depth of material on the vibratory feeder. There will be a reduction of the flow and volume of material moved by using a lower bed depth.

Frequency of the vibration applied to the feeder tray

Frequency of the vibration applied to the feeder tray

The starting point for frequency selection is understanding the type of material and the most effective frequency. Different materials respond better to different vibration frequencies, which influences the vibrators selected for the hopper feeder application.

When using rotary electric vibrators, we have four base frequencies: First, 2-pole vibrators that operate at 3600 vibrations per minute, we get the highest frequency resulting smallest amplitude of vibration. We can go down in frequency from the 2-pole vibrators to 4-pole with 1800 vibrations per minute. Third, 6-pole with 1200 vibrations per minute. Finally, an 8-pole, 900 vibrations per minute motor will generate the lowest frequencies.

With equal force, the lower frequency vibrator will produce the largest amplitude of vibration on the same piece of equipment. Heavier materials tend to require higher frequency drives, while lighter materials feed more effectively with lower frequency drives. Frequency and amplitude make a significant impact on the rate of material flow.

Amplitude of vibration or stroke generated by the feeder itself

As noted, the frequency of vibration strongly influences the amplitude of the feeder. However, another important factor to consider is force. We recommend vibrators that will achieve the requested feed rate. This selection is based on both the frequency of vibration and the maximum force output of the vibrator. With rotary electric vibrators, we can select the appropriate vibrator for your hopper feeder based on force output. Necessary adjustments to the eccentric weights can be made to reduce the force output from the unit’s rated maximum. More force output will result in a larger amplitude or stroke of the finished equipment for a given frequency.

Check out this video from vibration expert Kate Morel summarizing the movement of material down the feeder tray:

Material type can effect the flow of material

It can be challenging to visualize what’s happening when a fluid material is conveyed down the vibratory feeder. Here’s a quick tip: try thinking of the material flow as solid material being “extruded” down the feeder tray. This is like those videos of glaciers pushing into a body of water where the glacier’s leading edge initially falls off.

If soft material is being extruded, say fudge, for instance, the material will be thinner if we adjust the height of the hopper gate. As the material reaches the end of the vibratory tray, it’s as if we’re “cutting” off a strip of material the width of the vibratory feeder tray with each stroke of the unit. With higher frequency units we get more “cuts” per minute, and we’d expect to see more slices of fudge piling up near the end of the unit. We’d see fewer slices of fudge per minute using slower frequencies of the same force. But, we would get a longer, thicker strip with each cut due to the larger amplitude produced by the slower frequency. The larger amplitude pushes more fudge off the end with each vibration, but we get fewer slices since there are fewer vibrations.

So, back to our local customer

To give them consistency in the depth of material filling their trays, adjustments were made to the following:

- Hopper gate height

- Weight settings on the vibrators

- Operating frequency via adjustments made to the VFD

Our first adjustment was to the hopper gate to get a relatively thin layer of material in the vibratory tray. After waiting some time for the system to reestablish equilibrium, we started changing the size of the “cut” and the frequency with which we made those “cuts” at the end of the feeder tray.

We achieved the desired results by setting the vibrator weights to 80 percent and the VFD speed to 55 hertz. With these settings, we could sprinkle a thin well-controlled layer of his dry material onto the trays. Changes in the speed of the belt conveyor moving the trays would also influence the final results, but once we agreed upon a set speed for the belt conveyor carrying the trays, we successfully adjusted the parameters of the hopper feeder to accomplish the task.

Generally speaking, options are a good thing. With a vibratory hopper feeder and a variable frequency controller, options for the controlled flow of dry material of consistent size and density are plentiful. By working the available parameters one at a time, many bulk material flow applications can be successfully tackled.

Have more questions? We are happy to help. Contact us today!

Share this blog post:

Follow us: