Self Help: How To Check If Your Rotary Electric Vibrators Are Working Properly

By CVC Team

Counter Rotation and Synchronization

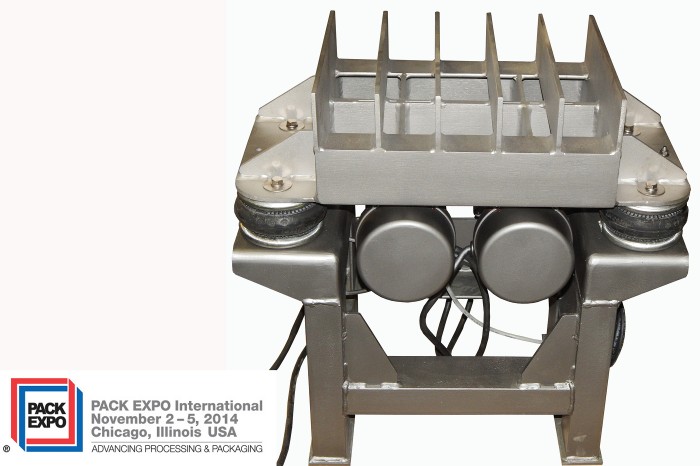

We manufacture a complete line of vibratory equipment. The product line includes a variety of vibratory table configurations, including flat deck, low-profile, grid top, and belt vibratory tables, along with Electromechanical feeders (EMF) and Electromechanical screeners (EMS). Many of these units are of the general “brute force” design type. This broad design category is based on the principles of counter-rotation and synchronization for two electromechanical rotary electric vibrators.

Counter Rotation of Your Rotary Electric Motors

Brute force units require the use of two rotary electric motors. When mounted to a rigid structure, the vibrators will “sense” each other and attempt to run at the same speed. When operated alone, a rotary electric vibrator will produce a rotational or centrifugal force. However, to produce linear force with two vibrators, the pair must run together and Counter Rotate. When mounted side-by-side and viewed from the end, one vibrator must run clockwise, and the other vibrator must run counter-clockwise. In typical applications, it isn’t important which vibrator runs in which direction. However, they must run in different directions.

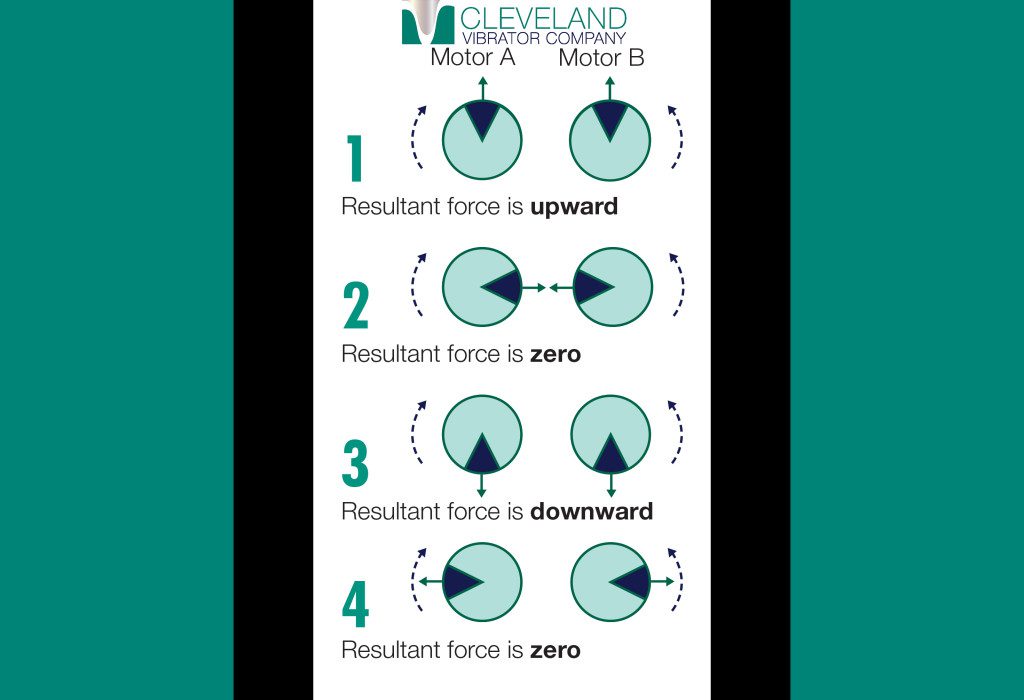

When running properly and in opposite directions, the forces produced by the two vibrators cancel each other except for two times in a cycle when the eccentric weights of the vibrator both point in the same direction. With the Cleveland Vibrator line of three-phase powered rotary electric motors, changing the direction of rotation on one of the vibrators is as simple as “flipping” two of the power legs of the vibrator. Below, you can check out a diagram showcasing counter-rotation and force cancellation.

Rotary Electric Vibrator Force Cancellation

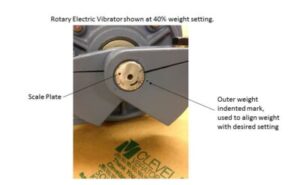

For the sake of completeness, let’s take a moment to discuss the design of the rotary electric vibrator. Very broadly, the rotary electric vibrator is a through shaft motor with bearings on each end of the shaft. Outside of the bearings, two eccentric weights produce an “unbalanced” condition when the motor runs. This unbalanced condition produces the vibration used to move, screen, or compact a variety of products. The eccentric weights are “pie-shaped” and are clamped onto the shaft with a bolt. The eccentricity, or unbalanced condition, of the motor can be varied from 0 – 100% based on the relationship of these weights.

Adjusting the Eccentric Weights on Your Rotary Electric Motor

To access the eccentric weights, remove the four bolts that hold the weight cover in place. Then, remove the weight cover. The outer weight, the one furthest from the center of the vibrator on each end of the vibrator, can be rotated to a new location changing its relationship to the inner weight. This adjusts the unbalanced condition, thereby increasing or decreasing the force output of the vibrator.

Never change the location of the inner weight; only adjust the outer weight. If one outer weight is changed, then ALL outer weights on both vibrators must change.

On each end of the motor shaft, you’ll see a dial with increments between 0 and 100 percent. The outer eccentric weight has a small “punch mark” or “dot” on the face of the weight. The punch mark is aligned with the desired weight setting on the dial. See the photo to the left, which shows this “punch mark” with the dial set to 40%.

Counter Rotation Example

If the goal is to reduce the force produced by a vibratory table, the customer might decide to “turn the weights back”. In other words, change the position of all outer weights to say 40%. All four outer weights are rotated so their punch marks align with the 40% mark on the dial on the end of the shaft. The unbalance of the vibrator is reduced by changing the relationship of the inner to outer weights. This also reduces the force it produces at any given speed.

On a piece of equipment, it is critical to the success of the operation and the serviceable life of that unit that all outer weights on each end of both vibrators are set in the same location. Refer to the rotary electric manual or call us if you have any questions. It’s crucial that all weights are properly set.

Rotary Electric Vibrator Synchronization

Once the outer weights are set the same and the rotation has been checked to confirm counter-rotation, the unit can run and the vibrators checked for synchronization. Synchronization simply means that the vibrators are running at the same speed in opposite directions and thereby producing linear vibration. When supplied by us, typical controls for equipment are either a magnetic starter or a variable frequency drive (VFD). They must start together and be controlled by one starter device.

While doing a final check on the equipment prior to shipping, we will periodically check for synchronization of the vibrators. To check for synchronization, one weight cover is removed from each vibrator exposing the two eccentric weights on the same end. Once the covers are removed, the unit is restarted and run. Use caution when operating the vibrators with the weight covers removed.

While the unit is running, a strobe tachometer is used to “stop” the motion of the rotating weights. This allows you to check to see that the vibrators weights are a “mirror” of each other. To “stop” the motion of the vibrators, adjust the frequency of the strobe to match the operational speed of the vibrators. At the operational speed, the motion will appear to “stop”. Now you can easily observe the relationship of one set of weights to the other. You can see this process in action in the video below.

In the video, the initial frequency of the strobe was slightly off that of the motors. As the speed of the strobe approaches that of the vibrators, the two sets of weights appear to slow to a “stop”. As seen in the video, the orientation of one set of weights should be mirrored onto the other vibrator. When the weights appear to “stop” and the orientation is observed, the position of the weights should be a mirror copy of each other. If this is not the case, then the vibrators are not synchronous and will not produce linear motion. This is not the desired condition for successful operation for vibratory equipment utilizing the brute force design.

What does it mean if the vibrators are not running together in synchronous operation?

This could indicate a problem with one of the vibrators, perhaps an early indication of pending bearing failure or lack of grease on the vibrators with grease fittings. Please refer to the operation manual for the recommended maintenance schedule for grease application, both quantity, and type of lubrication. Some of the smaller vibrators are permanently lubricated and don’t require maintenance of this type. Another option would be to double-check the tightness of the vibrator mounting bolts. As discussed in the maintenance manual, the vibrator mounting bolts should be checked periodically for tightness. Loose bolts can prevent proper operation and synchronization of the two vibrators.

If you have any questions, our friendly and knowledgeable Sales and Services Team is here to help. Contact us today!

Share this blog post: