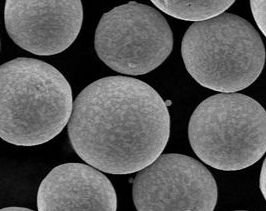

Sometimes a screening application cannot be solved by simply placing the product on the sieve surface and allowing the screener to do its job. For example, round screeners are designed to separate material by particle size. However, this simple process can occasionally cause problems or damage to the product and require the HK Ultrasonic Sieving System to properly separate the material, specifcally spherical material like solder powder (see picture).

What happens when spherical material is on the screen surface too long?

Damage or oxidization can occur to the spheres if left on the screen surface too long. Particle size separation is also very critical. More difficult-to-sieve powders fall into different categories based upon size: Type 4 (-400 +635 mesh), Type 5 (-500 mesh), Type 6 (-635 mesh), and Type 7 and 8 which have a slow sieving process.

The Model HK Incline

Recently, a customer inquired about a standard lab fine mesh ultrasonic sieving demo of his Type 4, 5, and 6 solder powder. Solder powder is generally very spherical and sieves very well when applying the HK Ultrasonic Sieving System to the screen surface. Our small lab models use 8” or 12” diameter sieves equipped with our HK Ultrasonic Sieving System.

Just as we thought, he called after a couple of weeks of working with the demo and said the lab unit was very efficient at sieving the powders. However, the length of time the powder spent on the sieve surface damaged his spheres. We explained that we will need to remove the covers off the screen surface in a much quicker time frame while still removing all of the fines.

Our suggestion was to try our HK Incline. To visualize, please check out the video below. The HK Incline is a very unique Ultrasonic Sieving System that utilizes rectangular screen frames and no mechanical vibration. We designed the HK Incline to rely strictly on ultrasonic energy to move the powder down the screen surface.

Here’s how it works:

You load a small hopper/feeder with your powder and a small electromagnetic feeder feeds the powder onto our special ultrasonic rectangular sieve frames. While the ultrasonics are pulsing on/off, the powder is moving down the screen surface. The fine grain particles pass through the sieve either on to a second mesh or into a fine grain collection funnel. The oversized materials are discharged off the ends of the screen frames into collection containers.

Moreover, what we like about this style of equipment is the ability to adjust the feed rate and product yield. There is a little bit of magic on our end in designing the screen frames and adhering the sieve material to the frames but the end result is a very efficient Ultrasonic Sieving System. Check out this product data-sheet to learn more.

So, back to the customer. After trying out the HK Incline with the HK Ultrasonic Sieving System on his solder powder, he loved it!

Keep in mind, the HK Incline is not for every application. If you have a powder that agglomerates or does not flow well the HK Incline will not be effective. But if you have a fine, free-flowing powder the HK Incline could be your ticket.

Want more information about this product? Contact us today!

Jeff Hochadel has over 25 years of experience building and selling vibratory screening equipment. Jeff is responsible for handling fine mesh screening applications for The Cleveland Vibrator Company. His expertise is utilizing our Ultrasonic Deblinding System to solve difficult screening problems. When Jeff is not visiting customers promoting our products you can most likely find him fly fishing.

Share this blog post:

Follow us:

3 Responses to Fine Powder Screening and Timely Solutions: Ultrasonic Sieving Systems