In a recent blog, we talked about the importance of “Counter rotation and synchronization” in the successful operation and maintenance of vibratory equipment. Now, we will touch on what you should do to properly adjust the eccentric weights on your rotary electric industrial vibrator. Although these steps are straightforward, they are crucial to the operation and longevity of the vibrator. Properly setting your eccentric weights can assist in keeping your equipment and vibratory investment free from damage. This is a great opportunity for us to expand on this subject, and, to be honest, we just LOVE spreading #VibrationEducation!

How to calculate vibratory force?

First, let’s delve into everyone’s favorite subject: Math. Understanding these concepts can help explain why setting your eccentric weights is important, and how it impacts your industrial vibrator and equipment. Any type of rotating vibrator, that includes rotary electric (RE), ball, or turbine vibrators generate their vibratory force by rotating a mass around the center of the unit or shaft. The force produced is dependent on three parameters:

- Weight of the rotating mass

- The distance of the center of gravity of that mass from the center of rotation

- The rotational speed

One of our old college vibration textbooks presents the formula Fo = moeω2 , where mo is the mass of the rotating unbalanced weight and e is the distance from the center of gravity of the rotating unbalanced weight to the center of rotation and ω is the circular frequency of the industrial vibrator (Phew!).

However, we’ve found that converting it into this slightly more user-friendly configuration does the trick, F = 2.85E-5 x unbalanced x rpm2. Unbalanced is the weight of the rotating mass times the distance from the center of gravity of that mass to the center of rotation, units being inch-pounds.

When working on and designing our turbine vibrators, we’ve had to calculate the “unbalanced” of each particular unit. Fortunately, the weight and center gravity of the unbalanced mass is easily determined with our 3D modeling software.

Why is setting the eccentric weights important?

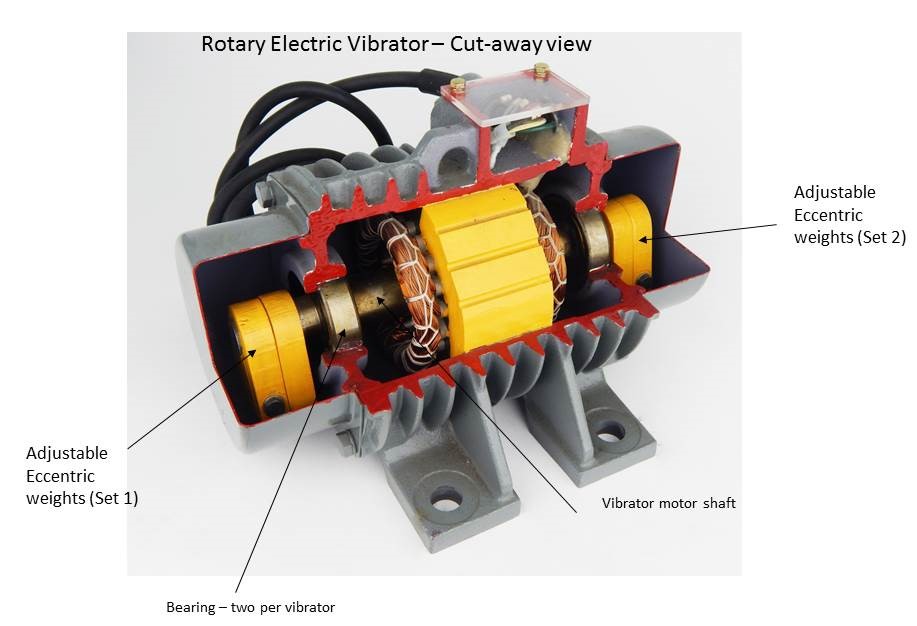

The rotary electric vibrators are designed with two sets of weights mounted on each end of the motor’s shaft. Take a look at the cutaway photo below for the basic design. These weights become the “unbalanced” mass that is used to generate vibratory force as the vibrator rotates. The keyword here is Unbalanced, to produce the vibration, the rotating mass must not be balanced.

The two sets of weights on the industrial vibrator’s shaft can be rotated relative to each other to produce a maximum unbalanced value resulting in the highest force output at a given rpm. Similarly, the weights can be adjusted so they oppose each other and become balanced. In this case, the balanced rotating mass produces no vibratory force. It’s critical that what is done to one end of the vibrator must be done to the other end. Individually, the vibrator is not designed to operate with unequal weight settings end to end. This configuration will reduce the productive life of the vibrator and may produce destructive forces on your equipment.

Additionally, if the vibrators are mounted to a piece of equipment any adjustment made to one of the two vibrators must also be done to the second vibrator. This includes vibratory Screeners (EMS), Feeders (EMF), or any one of our many Tables (FA, FA-O, GT, etc.). Likewise, on a piece of equipment, both vibrators need to be set in the same manner. All weights on both vibrators must be in the same orientation relative to each other. In other words, consistency is key!

Now, to the fun part.

Steps to adjust eccentric weights:

- Disconnect the power supply to the vibrator to prevent unintended or unexpected starting of the vibrator while adjusting the weights.

- Using the appropriated sized wrench, remove the four bolts that hold the vibrator’s weight cover in place. Repeat on the opposite end of the vibrator.

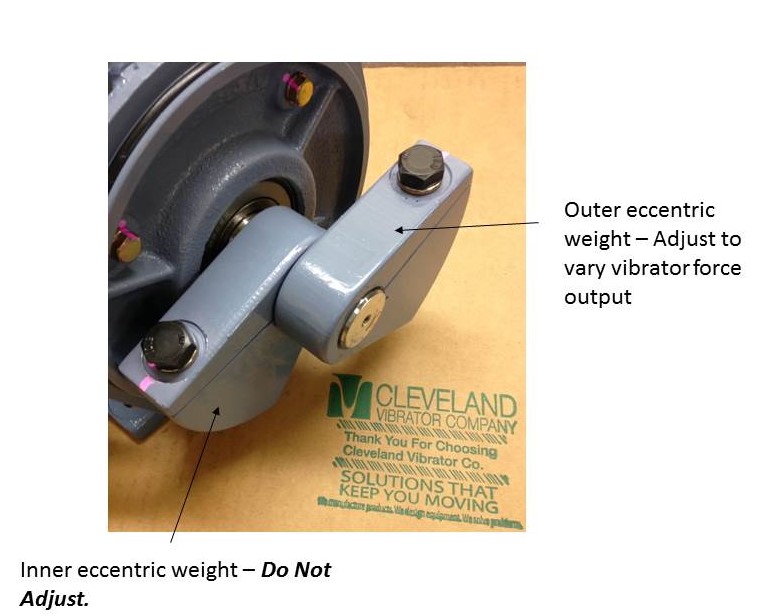

3. Once the cover is removed the weights can be adjusted. As shown above, each end of the industrial vibrator has two weights, an inner weight and an outer weight. Do not adjust or move the inner weight. To adjust the force output of the vibrator, only adjust the position of the outer weight. Loosen the bolt that clamps the weight to the shaft. Once the bolt is loosened the weight can be rotated about the shaft to a new position.

Caution: If you’re making an adjustment to a vibrator mounted on a piece of equipment or on a hopper where the shaft of the motor is perpendicular to the ground, once the weight clamp bolt is loosened the weight can drop off the vibrator.

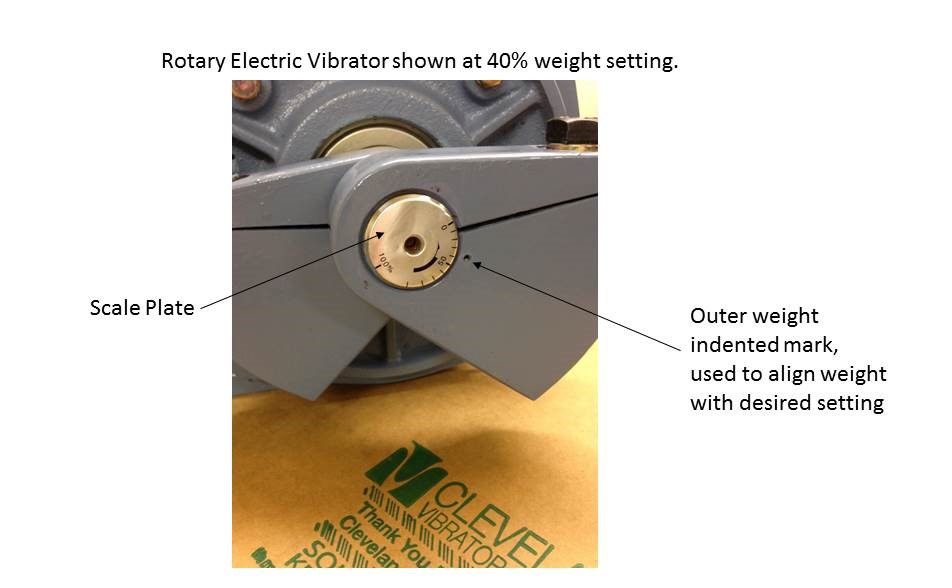

Be sure to maintain control of the weight as you rotate it on the shaft. The photo below shows the end view of the weights and the scale plate. As shown, the outer weight has an indented “punch mark” on its face that is used as a reference point when adjusting the weight. The scale plate is incremented from 100%, maximum force output, to 0%, a balanced weight arrangement, resulting in no vibration. Increments are in 10% interval for easy adjustment and alignment of the outer weight.

4. Rotate the outer weight to the desired new setting. Use the punch mark as a guide; center the punch mark with the line on the scale plate that corresponds with the new setting. In the photo, the vibrator is shown at its factory setting, 40%.

5. After rotating the outer weight to its new location, retighten the weight bolt, clamping the weight securely to the vibrator shaft. After tightening the weight clamp bolt, check to make sure the weight didn’t move while being tightened onto the shaft. If the punch mark is off the desired scale plate mark, loosen the bolt and reposition the outer weight. Retighten the bolt and make sure the weight is fixed to its new location.

6. Repeat the weight adjustment procedure on the opposite end of the vibrator. As stated before, it is very important that the outer weight on each end of the industrial vibrator is set to the same position as indicated on the scale plate. For example, if one outer weight is set to 80% the other weight must be set to 80%.

7. Replace the weight covers on the vibrator. Ensure that all weight cover bolts are used and tightened in place.

8. If the vibrator that was adjusted is mounted to a piece of vibratory equipment that uses two rotary electric vibrators, repeat this procedure on the second vibrator. Remember, both vibrators must have identical weights settings on both ends of both vibrators.

9. Finally, record the new weight settings for future reference and return the vibrator to service.

This completes our step-by-step process on how to adjust the weights on a rotary electric vibrator. If you want to see these steps in action, check out the tutorial video on our Youtube channel!

Are you looking for a shorter version of this how-to? Click the image below for a simplified infographic.

If you have any questions or want to learn more, our team is here and happy to help!

Share this blog post:

Follow us:

12 Responses to How to Properly Adjust the Eccentric Weight on your Rotary Electric Vibrator