Along with our other vibratory equipment, vibratory feeders are great problem solvers. Feeders are well-known for their ability to move material from point A to point B effectively. However, a well-designed vibratory feeder offers flexibility to the end-user and increased safety and efficiency in the process.

Feeders can range from small base mounted CF-A, pneumatic powered feeders moving small quantities of dry bulk material in a controlled manner to a much larger base, as well as a cable-supported EMF, electromechanical feeder conveying literally tons of material an hour. This breadth of design capabilities allows our vibratory feeders to move material effectively in various industries for many different applications.

For example, we have incorporated vibratory feeders into the processes of these materials and more:

- Almonds

- Crushed Limestone

- Shelled Corn

- Powdered Metal

- Metal Billets

- Various Pipe Fittings

- Scrap Brass and Bronze

- Crushed and Shredded Automobiles

- Hot Dross

We work with a variety of industries feeding an endless variety of materials!

Here are the questions you should ask yourself when determining the parameters that influence sizing and design:

- What is the inlet and discharge conditions for that piece of equipment?

- How is the material being placed on the feeding surface?

- What are the dimensions of the incoming stream of material?

- Is the material being dumped a batch at a time or via a near-continuous follow at a known rate?

- What’s happening at the discharge end of the unit?

- Does the unit feed another piece of equipment such as a belt conveyor, bucket elevator or perhaps a furnace?

- And of course, what are the specific properties of the material including the bulk density and particle or part size?

A quote or design will typically start by addressing two main parameters:

- What is the material volume that must be moved?

- How far do we have to move it?

How far the material needs to move drives the length of the unit. To interface with the receiving equipment, you may also require adjustments to the length of the tray. The volume of material moved per hour plus the material’s bulk density will drive the width and depth of the vibratory tray. If the equipment that passes the material onto the vibratory feeder doesn’t restrict the feeder’s width, we then look at the volume and density of the material.

To calculate the cross-sectional area for material flow based on the rate per hour and bulk density, we’ll need an estimated linear velocity for the material. Once we’ve calculated that cross-sectional flow area, we factor in the tray width and see what happens to our depth of material on the vibratory tray. Once everything looks good and makes sense for the specifics of the application, we’ve arrived at the final size and specifications for the vibratory feeder.

What options are available for your Vibratory Feeder?

A well-designed and properly installed vibratory feeder is a thing of beauty! Simple and effective, it lives to move material from point A to point B. These feeders are mechanically very clean and virtually maintenance-free. A variety of appropriately sized robust and quiet air-cushioned pneumatic piston vibrators drive small air-powered CF-A units. Supply clean and lubricated air to these units, and they’ll provide dependable service for a very long time. Similarly, the equipment will have a long operational life and effectively move material for years if powered by Uras Techno Rotary Electric Vibrators.

Without a doubt, the most common use for a vibratory feeder is to move material as described above. Still, many of our customers also use vibratory feeders to add or spread dry material onto the surface of their products.

Vibratory feeders can be used to meter one product onto the surface of another product with consistent density and particle distribution when conveying dry material.

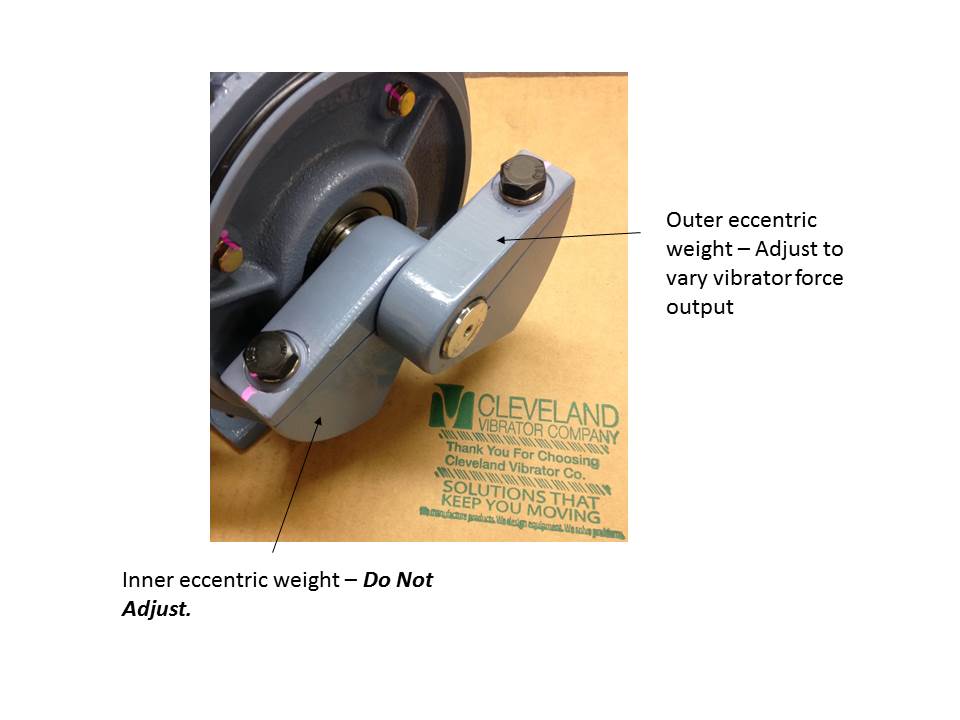

Moreover, we have customers who use our EMF units to apply a layer of dry product onto the surface of a moving product as it passes under the feeder. By adjusting the operating speed of the vibratory motors and/or the eccentric weights, operators can dial in the right combination of frequency and force to apply a consistent and repeatable volume of material onto the surface of their product to successfully meet their rate requirements.

Now, how have we applied Vibratory Feeders in real-life situations?

Problem:

We visited a potential customer’s facility to review an application similar to the one above. The company is looking to improve its method of applying a granular product onto the surface of its raw product as it moves down a conveyor belt. Currently, they have a hopper mounted above the conveyor and a rotating knurled cylinder on the bottom opening of the hopper. Rotating the cylinder is intended to permit the material to drop onto the moving product. Unfortunately, the material size varies a bit, and that different sized material is important to the process, but it also creates a problem. Jams and inconsistent spreading of the product are common and reduce the quality of the finished product.

Cleveland Vibrator Company’s Solution:

After looking at their current process, we suggested the use of a cable suspended vibratory feeder. Different-sized particles can be easily conveyed without concerns about jamming due to the open nature of the feeder. By adjusting the operating speed and force output of the vibrators, the feeder can spread a consistent layer of the secondary product edge to edge onto the material below. Furthermore, coupling the feeder with a small storage hopper would ensure that the feeder has a plentiful supply of material, critical in making sure the feeder maintains a consistent and repeatable thickness of material on the vibratory feeding surface. As a result, they have a well-controlled and regulated volume of product conveyed by the feeder.

In short, it’s worth considering that a properly sized, designed, and installed vibratory feeder can be a real problem-solver. Well-designed feeders can successfully move a wide variety of products from point A to B and can be used to meter or spread one product onto another.

For more information, our friendly and knowledgeable Sales & Services Team is here to help! Until next time Movers & Shakers, stay connected with us to get more #VibrationEducation!

Share this blog post:

Follow us:

One Response to How to Design and Size a Vibratory Feeder Conveyor Based on Application Requirements