When dealing with dust collection systems, it is critical to regularly clean the collected dust out of the equipment. One of the methods to remove the accumulated dust is with the help of vibration. Where the vibration is applied, though, depends on the collection system installed. Standard installations that we see are:

- Electrostatic Precipitators (ESP)

- Baghouses

- Cyclones

Electrostatic Precipitators

First, we’ll discuss electrostatic precipitators. These are large systems that are frequently found at facilities, such as:

- Pulp and paper or steel mills

- Refineries

- Concrete plants

- Coal-fired power plants, just to name a few

The systems have a series of wires and plates that act as filters that rely on an electrostatic charge to pull dust particles from the air passing through the collection system. Keeping these wires and plates clean is imperative to the process because it helps increase the efficiency of the dust collection system.

This is where a Rapper comes into play.

The Cleveland Vibrator 3″ PMA Rapper is an air-powered piston vibrator that is installed on a mounting plate connected to a shaft to shake the wires and plates. This shaking process breaks the friction of the particulates clinging to the collection media. The dust then drops down to the collection hopper underneath. Once the material is in the collection hopper, an externally mounted piston vibrator or air knocker will remove the dust from the inside sloped walls of the hopper and to the discharge.

For a helpful visual aid, check out this video on YouTube, courtesy of Thermax Global.

Baghouses

Many baghouses use pulses of air to clean out hanging bags inside the system, which causes the particulate to drop into the collection hopper below. Once the material reaches the collection hopper, vibrators clean off the inside sloped walls. This ensures material reaches the discharge outlet or the feeder underneath.

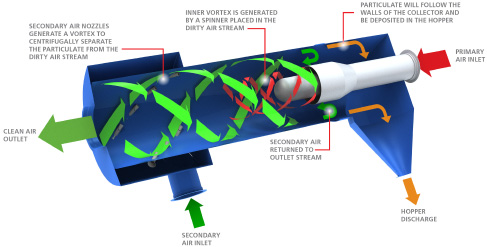

Cyclones

These systems rely on the shape of the vessel, and the directional flow of air pushed into the vessel to spin particulate and create a vortex. The gravity of the particulate helps this material drop to the hopper underneath while the cleaned air, which is lighter in density, exits the exhaust vent at the top of the collector. Once the dust reaches the hopper bottom, an industrial vibrator will move that material into the discharge below.

Our friends at Aerodyne have posted this video on YouTube to give a demonstration of a cyclone working.

One of the biggest keys to longer-lasting equipment is proper maintenance. Installing a rapper, air knocker, or piston vibrator can help keep the collectors clean and running as expected.

For more details on what Cleveland Vibrator has to offer for dust collection systems, contact us or give us a call at 1-800-221-3298. Our team is happy to review your project!

Mike joined The Cleveland Vibrator Company team in 2013 with prior experience in manufacturing sales with a Cleveland company in the tool and die industry. Now, he’s the Director of Sales and specializes in “making stuff that shakes stuff”.

When he’s not immersed in the world of industrial vibration, as rare as that might be, Mike keeps busy *not finishing in last place* in Fantasy Football and enjoys spending time with his wife and three kids. It’s always golf season for Mike, and he’s been known to 3 putt his way around any course and can roll tee balls in rain or shine. You can find him tailgating in the Muni Lot before Browns games or supporting local breweries.

As an avid provider of #VibrationEducation, he offers this free bit of advice, “Not all vibration is the same. Force and frequency do matter!” However, there is a 2% upcharge for all Michigan and Steeler’s fans.

Share this blog post:

Follow us:

One Response to How Vibration Helps Improve Dust Collection Systems