Valuing your worker’s safety and well-being are ideas that most can agree on is crucial for company success within dangerous industries such as Grain Handling. Part of my job is updating our Twitter Feed and keeping an eye out for industry news via shared stories and retweets by some of the most credible sources in the material handling industries. Recently, I have been seeing numerous stories about grain entrapment accidents and can’t help but wonder, why does this keep occurring when preventive measures are available? Safety and Health Topics on OSHA’s website can prove to be rather helpful and a great reference to industry procedures, so I started there in my quest to compile this list.

- Provide Proper Dust Collection Equipment Within Your Facilities – Did you know that between 1976 and 2011, there have been over 500 explosions within Grain Handling Facilities across the U.S. and have killed more than 180 people? This piece of equipment comes in a variety of designs which allows you to choose the best option for your facility (Manufacturers such as Aerodyne can provide help here). Applying vibration to your dust collector can offer the proper dust dislodging technique to help provide better safety for your crew. We have many vibratory solutions that can help with the proper upkeep of dust collection equipment.

- Properly Choose Location of Your Dust Collection Equipment – All filter collectors that have been installed after March 1988, should be located outside of your facility. This will help to reduce explosion hazards. If your piece of equipment is located within your facility, it should be protected by an explosion suppression system.

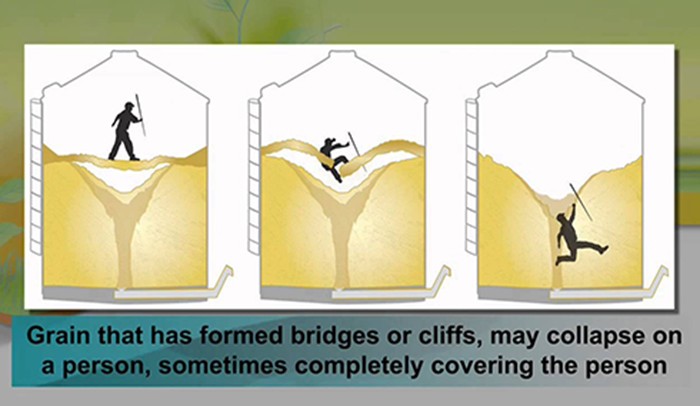

- Utilize Proper Vibratory Equipment for Grain Storage Bins – Suffocation is the leading cause of death in grain storage bins. It takes 5 seconds or less for a worker to be completely engulfed while they are trying to unclog the “bridged” grain. The behavior and weight of the grain create a quicksand-like rotation, making it extremely difficult for a worker to escape without assistance in many cases. Using an Air Piston Vibrator, such as Cleveland Vibrator’s VMSAC or SI Single impactor, on the sides of your storage bin can help reduce the need for bin/hopper entry.

- Power Down Any Excess Equipment Pieces Associated with Bin – Whether it be pneumatic, electric, hydraulic, or mechanical, any piece of equipment that is moving grain heightens the chances of engulfments since it could create a suction of the material pulling your worker into the grain in a matter of seconds.

- Provide All Employees with a Safety Harness – This harness should be connected to a lifeline and employees must wear this harness when the need to enter a bin should arise.

- Implement Preventive Maintenance Programs – Be sure to regularly schedule inspections of your mechanical and safety control pieces of equipment. When it comes to your Vibratory Equipment, Cleveland Vibrator can provide field tips and also evaluate your vibratory drives or equipment. You can learn more from our blogs about the importance of Vibratory Unit upkeep. This measure helps to maintain the highest level of safety precautions if utilized properly. Using equipment that is not up-to-date with current safety codes can prove to be a critical mistake which makes the odds of an accident greater within your facility.

For more information on this subject, visit OSHA’s web page to stay up-to-date with the latest protocols in your industry.

Looking to learn more about what Industrial Vibration can do for you? Click here to see it’s different applications or contact us!

***Photo Credit: U.S. Agricultural Safety & Health Centers: Following Proper Grain Bin Entry Procedures Saves Lives YouTube Video

Katy Sabo has been the Industrial Vibrator Duchess of The Cleveland Vibrator Company since 2014. The originator of #VibrationEducation, Katy has helped create CVC brand awareness across the globe and has made it her personal priority to share the importance of Industrial Vibration with anyone willing to listen! When she isn’t shaking things up in the Marketing Department, you can usually find her shopping with her favorite sidekicks (she’s the proud mom of two little ladies), going on long walks/runs with her favorite furry family members, or rooting on any Cleveland team with her diehard fan of a husband.

Share this blog post:

Follow us:

2 Responses to Top 6 Ways to Keep Your Employees Safe in the Grain Handling Industry