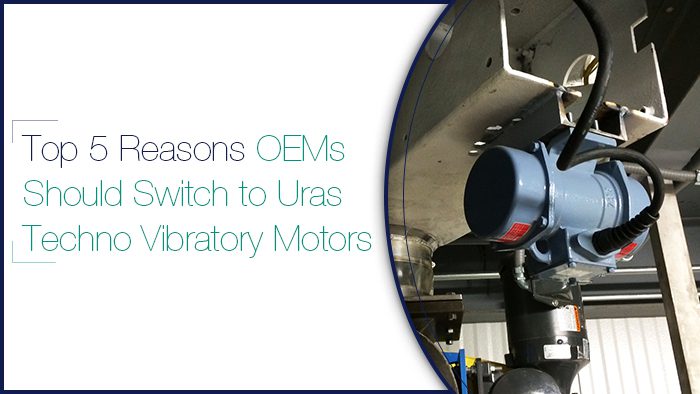

In 1978, we were approached by a company specializing in rotary electric motors: Uras Techno. Sharing our goal of providing vibratory units built to the highest quality standard with options to fit each customer’s unique application – we found our perfect match! Since then, we have been the exclusive USA stocking distributor of their rotary electric motors. Together, we have helped many now-happy customers make the switch from competing brands.

For example, a few months ago, an OEM (original equipment manufacturer) in the food industry was looking for an alternative vibrator for their feeder, which is used to transfer frozen fruit in their production process. The competing brand’s units had gaps in the design that were easily contaminated. This led to frequent downtime to clean the vibrators to avoid sanitary issues. Choosing to make the switch, they now experience less downtime thanks to their easy-to-clean Uras Techno stainless steel food-grade motors.

So, why should you take the leap and switch to Uras Techno?

Read More…Share this blog post: