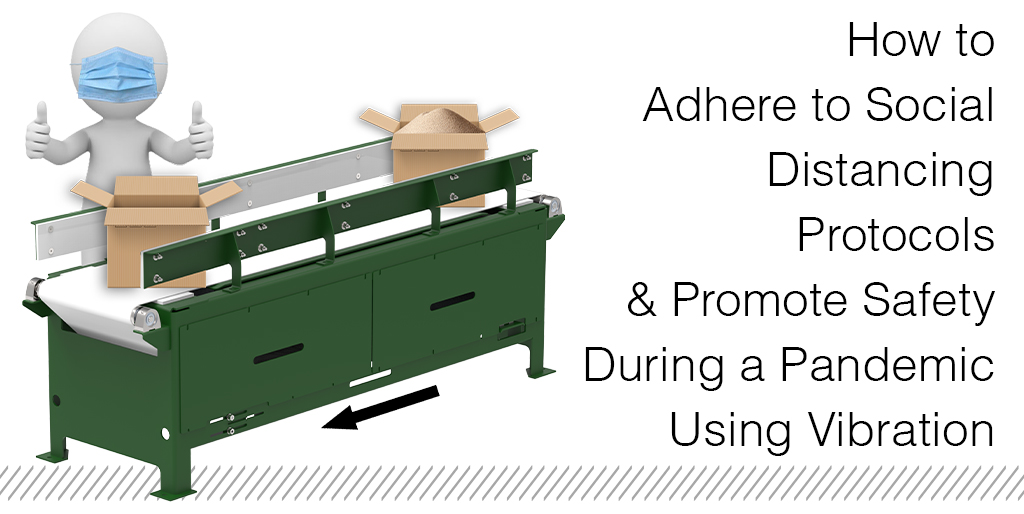

In this pandemic, manufacturers have been called on to help make items critical to stopping the spread of, or help with the treatment of, the virus. Namely, our nation needs an increased focus on the manufacturing of PPE, cleaning products, and ventilators. Well, we at Cleveland Vibrator Company are a manufacturer. However, we don’t have the capability to make masks, sanitizers, or ventilators. We are proud to be deemed essential and contributing to keeping the production and transportation of key goods intact. But we want to be doing more to directly contribute to stopping the spread. So, we were inspired to think of products and projects that have helped customers reduce the density of workers in a small area and could now apply to enable safe distancing on processing and production floors. Here is a couple:

Application #1: Bulk Food Packaging

Production conveyor line without the use of vibratory equipment – Cleveland Vibrator Company

In packaging bulk foods such as frozen onion rings, bagels, or meat patties, typically there is a step between the box filling station and the close and seal station to settle the product. When the box gets filled with products, especially odd-sized items, the product tends to cone so that amount of product that by weight is supposed to fill the box, is in a mound that exceeds the height of the box. Often, this settling is handled manually by workers standing shoulder to shoulder at the conveyor between the filling and close and seal to shake the boxes and get the products evenly settled. Read More…

Share this blog post: