It’s Halloween… Tales from a Small Town Boy Will Have You Shakin’ in Your Boots

By CVC Team

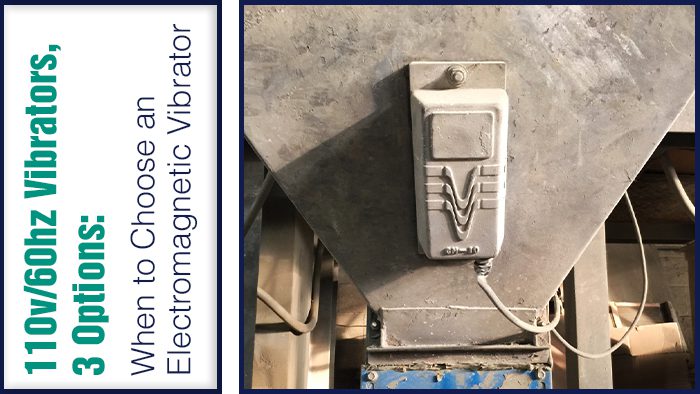

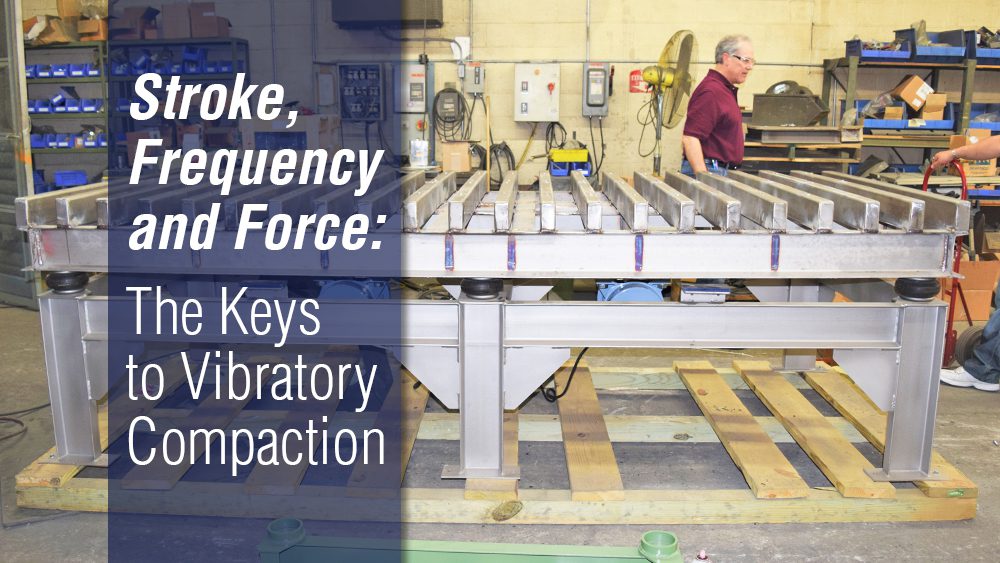

With Halloween approaching fast, it has reminded me that over the years Cleveland Vibrator has sold several vibrators to entertainment enterprises for use on their Halloween projects. One of these projects, I was told, was for a Haunted Mansion Halloween Party for a pretty well known publication here in the U.S. (*Mansion may be a pretty big clue here). They used two 1125 VMS Air Piston Vibrators mounted below the floor to surprise folks as they walk on them. We even built an “Earthquake Machine” for the Natural History Museum here in Cleveland, Ohio to give visitors the experience of what an earthquake may feel like. They even covered the drive motors so you could actually sit on them. This holiday also brought back an experience I had at a burial vault company visit just a few years past. But, before I tell this story would like to explain what led up to my reaction to this visit.

I think that our beliefs and fears about Halloween go back to what we have learned or were told as kids. This for sure applies to my background as a youngin’. I was raised in Southern Ohio on a small farm that had no phone service until I was twelve or thirteen. Read More…

Share this blog post: