Frequently Asked Questions About Rotary Electric Vibration

By Steve Chinn

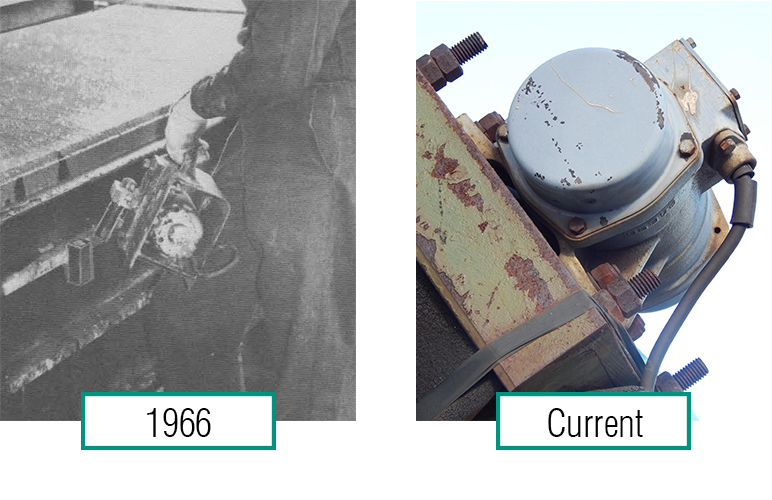

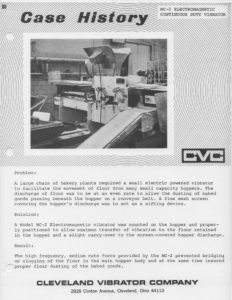

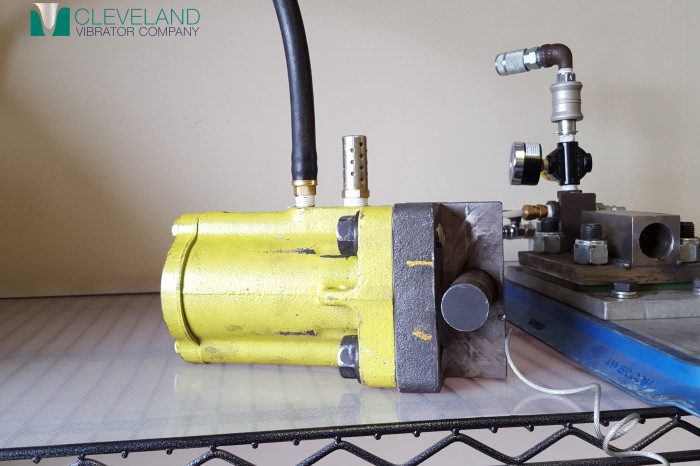

In 1923, The Cleveland Vibrator Company began its journey in the exciting world of industrial vibration, specifically the use of pneumatic powered options for foundry applications. As we ventured into other industries, we noticed a new trend: the demand for electric-powered motors.

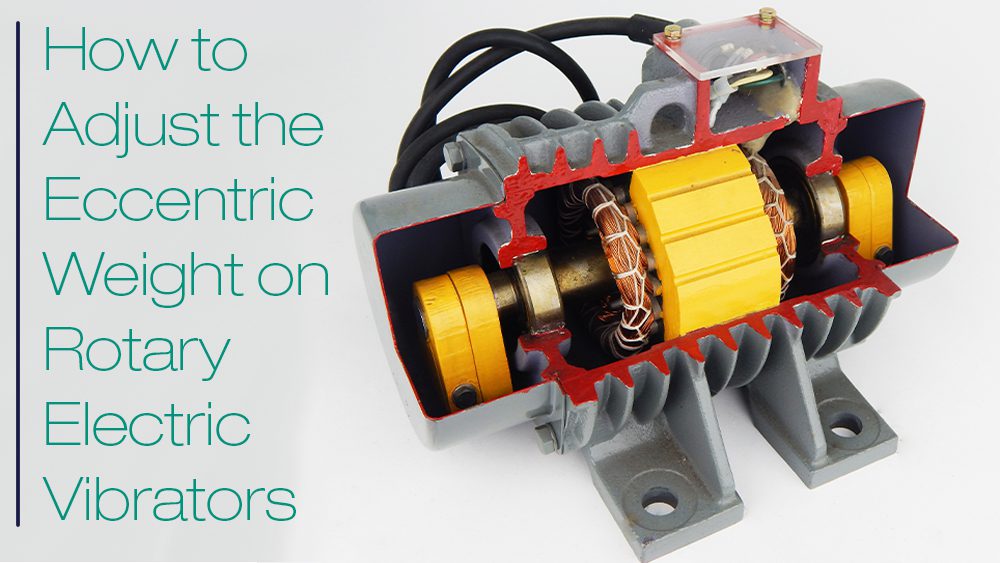

Soon after, we decided it was time to explore this exciting new opportunity and set out to find a partner specializing in electric-powered vibration. We eventually partnered with an outside company to supply this demand from our customer base. As with any new venture, we experienced a few hiccups along the way; lead times were too long, insufficient force options available, and the lack of “Cleveland Vibrator Quality” our customers came to expect.

Read More…

Joining The Cleveland Vibrator Company team as Sales Lead in January of 2017, Steve Chinn offers extensive knowledge and experience in the Bulk Material Handling industry. As a Cleveland State University graduate with a major in Communication and a minor in Marketing, Steve works closely with Uras Techno, the manufacturer of the high-quality Rotary Electric Motor product line exclusively distributed by The Cleveland Vibrator Company.

When not *almost* losing in our company Fantasy Football league, you can find this Cleveland sports fan golfing or spending time with his wife and two kids. He even coaches his kid’s baseball teams!

Share this blog post: