When it comes to unloading dry or semi-dry bulk materials from a hopper trailer, belly dump, side dump, end dump, or similar type of truck, a few vibratory options are available to the market. Depending on the power supply available on the mobile equipment, air or electric, the vibratory components change. We will first look at the air-powered vibrator options then turn to the electric-powered vibrator options.

Air Powered Options

Piston Style Vibrator

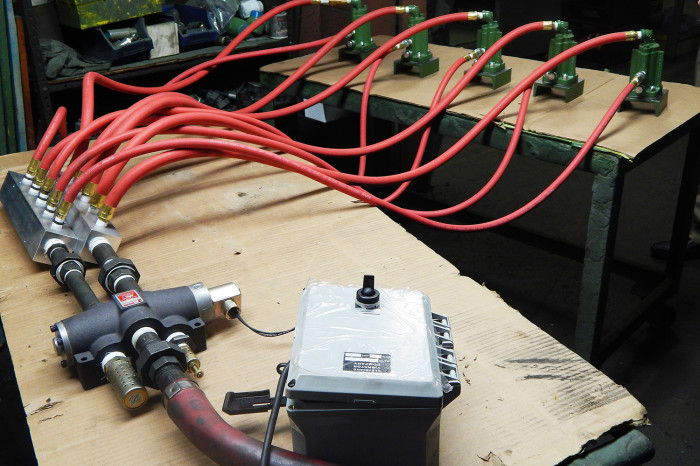

The pneumatic or air-powered units that are available are the piston-style vibrator or the turbine-style vibrator. These two are by far the most common air-powered vibrators found on mobile equipment. The Vibra-Might Air Piston Vibrators are popular units in the field because these vibrators have a dual-diameter piston that allows for start-up at any mounting angle, and there is no spring on the inside of the vibrator. No spring = less wear parts.

These vibrators also have a single exhaust port and come standard with the exhaust port protector. The exhaust port protector helps keep dust, dirt, water, and other contaminants out of the bore of the vibrator. These Vibra-Might air piston vibrators come in both 4-bolt square base and 2-bolt rectangular base designs. The 2-bolt design is more common, and the slotted bolt holes of the 1200 VMR (impacting piston) or 1200 VMRAC (non-impacting piston) cover a wide range of new or existing bolt patterns. Also, if there is no oiler or lubricator on the truck itself, we offer coated casted bodies that can operate with or without lubricant. Adding lubricant will help the longevity of the vibrator, but it is not necessary.

Read More…Mike joined The Cleveland Vibrator Company team in 2013 with prior experience in manufacturing sales with a Cleveland company in the tool and die industry. Now, he’s the Director of Sales and specializes in “making stuff that shakes stuff”.

When he’s not immersed in the world of industrial vibration, as rare as that might be, Mike keeps busy *not finishing in last place* in Fantasy Football and enjoys spending time with his wife and three kids. It’s always golf season for Mike, and he’s been known to 3 putt his way around any course and can roll tee balls in rain or shine. You can find him tailgating in the Muni Lot before Browns games or supporting local breweries.

As an avid provider of #VibrationEducation, he offers this free bit of advice, “Not all vibration is the same. Force and frequency do matter!” However, there is a 2% upcharge for all Michigan and Steeler’s fans.