MG Electric Truck & Trailer Vibrator: How To Quickly & Safely Unload Material

By Mike Stratis

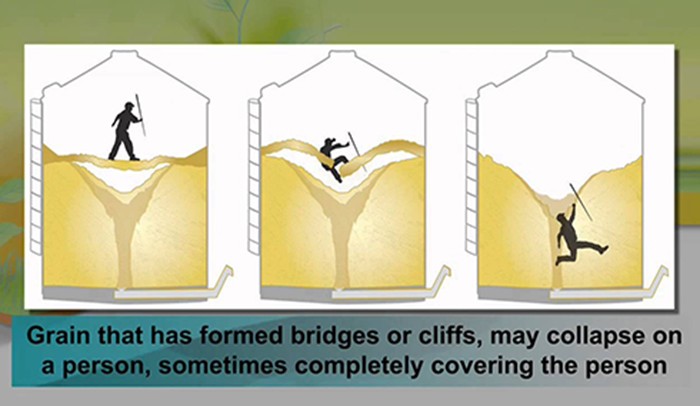

If you are in the truck and trailer industry servicing dry bulk materials, you know how much of a headache unloading materials like grain products, DDG, aggregates, and road salt can be when it sticks to the inside of your end dump or hopper bottom trailer. So, to ease the stress of these material flow problems, The Cleveland Vibrator Company introduced our 12 VDC electric-powered vibrators, the MG Truck and Trailer Vibrators, which are designed to handle tough material flow challenges and eliminate sticking material for any load size.

Mike joined The Cleveland Vibrator Company team in 2013 with prior experience in manufacturing sales with a Cleveland company in the tool and die industry. Now, he’s the Director of Sales and specializes in “making stuff that shakes stuff”.

When he’s not immersed in the world of industrial vibration, as rare as that might be, Mike keeps busy *not finishing in last place* in Fantasy Football and enjoys spending time with his wife and three kids. It’s always golf season for Mike, and he’s been known to 3 putt his way around any course and can roll tee balls in rain or shine. You can find him tailgating in the Muni Lot before Browns games or supporting local breweries.

As an avid provider of #VibrationEducation, he offers this free bit of advice, “Not all vibration is the same. Force and frequency do matter!” However, there is a 2% upcharge for all Michigan and Steeler’s fans.

Share this blog post: