Some time back in the mid-60s Cleveland Vibrator started working with coating technology in an effort to improve the performance and longevity of our line of pneumatic piston vibrators. For best operation, while consuming a minimum of compressed air, the piston and the body of any pneumatic piston vibrator need to be very closely matched. Clearance between the moving piston and the fixed body is very fine, in certain installation orientations, the piston rides on the body of the vibrator creating a metal-on-metal contact area. Because of the metal-on-metal contact, it is recommended to supply a pneumatic piston vibrator with lubricated air. The appropriate amount of oil mist in the air stream will lubricate the moving parts, reducing the coefficient of friction between the surfaces and extend the life of the vibrator.

Cleveland Vibrator’s investigation into and early use of friction-reducing coatings was designed to leverage the benefits of the coating to enhance the performance and extend the life of the vibrator by reducing parts wear due to friction. If not properly maintained and lubricated a piston vibrator will start to wear due to the piston/body surface contact. Indicators of excessive wear will be reduced performance, less force output, and more air consumed at the same operating pressure. As the piston and body wear over time, the gap between the two parts will increase, with the larger spacing air can “blow by” the piston, blow by air isn’t effectively used by the vibrator to generate force it simply exhausts out of the body. It’s pretty easy to see why CVC makers at the time saw a benefit to reducing internal friction and leveraging new technology in the form of various coatings to extend the life of the unit and provide more value to our customers. If the coating process could become a substitute or enhancement to oil mist lubrication, then the potential existed to significantly improve the effective work-life of the vibrator.

By the time I started at Cleveland Vibrator the use of friction-reducing “coatings” was the standard on a variety of the VMS (impact) and VMSAC (air cushioned) piston vibrators, an option on most other piston vibrators. Coated vibrators can be used for non-lubricated applications where the exhausting of compressed air with even a small amount of an oil mist is unacceptable. The use of the Super Blue or Super Grey coating process has been integrated into the manufacturing of many of our piston vibrators. When properly applied to the body of the vibrator, the coatings produce a surface with a very low coefficient of friction; significantly reducing wear even if used without lubricated air. If used with lubricated air, the lubrication enhances the effect of the coating to further reduce wear and extends the life of the vibrator.

It was understood across the company that there was a benefit to the coating process and this was supported by the longer life of the vibrators as reported by our customers. It only makes sense, reduce the friction and reduce the wear of the unit.

It only makes sense, reduce the friction and reduce the wear of the unit.

As long as the piston and body are within specs, the unit performs well and we avoid air blow by and the resulting reduced life of the unit. But no one seemed to have any data or test results to support this widely held belief, customer feedback, or not. About a year ago a sales team member was tasked with doing a bit of research into the coating process, materials used, and benefits to CVC’s product line. Results of the effort showed that the coefficient of friction for metal surfaces treated with both the Super Blue and Super Grey is very small and very close to each other. The Super Grey has a much higher operating range, rated to 1200°F, with the Super Blue carrying a rating of 500° F. as a result the Super Grey is commonly used on vibrators with a higher temperature rating. But we couldn’t really quantify the improved performance and extended life of a coated vibrator based on the data we had at the time. So we decided to run a little test and see what we’d see, did the coatings in fact extend the life of the vibrator, and was one of the coating materials better than the other. For the purposes of our test, “better” simply means that the coating helps the unit run longer.

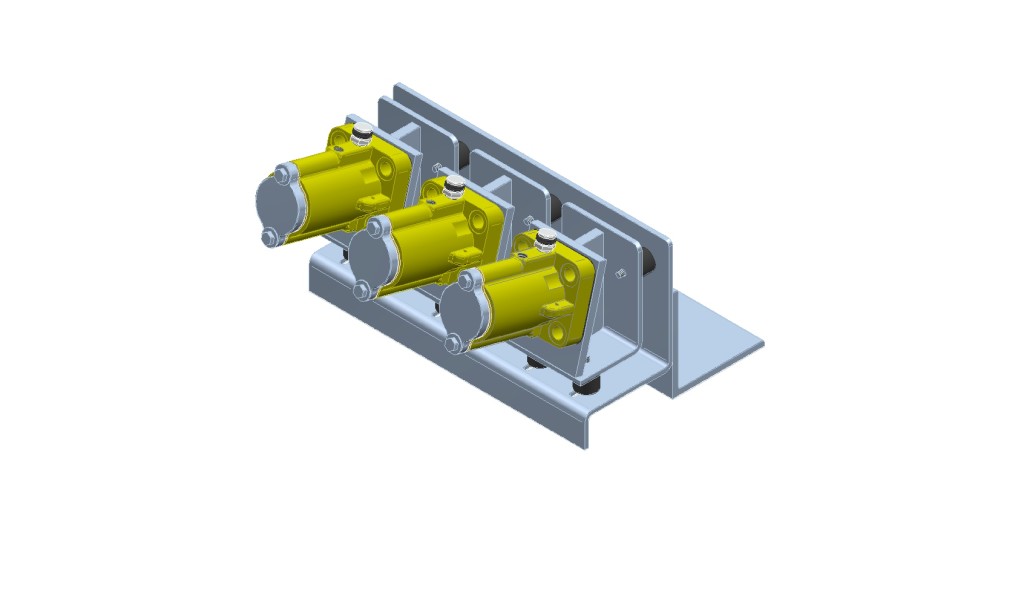

Our test setup was pretty simple as well as our plan. We took three 1150 VMSAC units from stock, coated the body bore of one with the Super Grey process, the second with the Super Blue and the third unit received no coating or additional post-machining processing. The three units were mounted on a common base and individually isolated as shown below. A single source of filtered non-lubricated air was brought to the test stand then individually branched to each vibrator. The vibrators are mounted at a slight angle, 15 degrees from the horizon, in this configuration gravity will naturally case the piston to rub on the body as the vibrator cycles. On August 28, 2015, we set the pressure regulator to 60 psi, turned the ball valve, and started the vibrators running.

Periodically during testing, we measure the operating frequency, acceleration (measured using an accelerometer magnetically attached to the cap), and the temperature of the cap and the body. Early on in testing, I noticed a difference in temperature of the cap and body between units, my theory was that higher heat was an indicator of more friction within the unit and potentially an indicator of which unit would fail first. Typically the units are started in the morning and run continuously for eight hours five days a week.

As expected the standard non-coated unit was the first vibrator to stop operating. This makes sense, without the use of the recommended lubricated air the unit would eventually run “dry” and metal-on-metal rubbing would take place. So after 347 hours of non-lubricated operation, the standard unit didn’t start when the burst of air was applied. Not too bad, given the operating frequency of the 1150 VMSAC, 347 hours equates to over 41,640,000 cycles! That’s a lot of shaking. The big question when the standard unit wouldn’t start was how much longer would the coated units perform how much value in terms of longer operating life would the coating provide? No real way to predict; only time would tell.

As of June 15th, both coated units are still running. Performance has remained with 5-10% of the values we captured at the start of the test. The total time of operation for the vibrators is 1615.9 hours of continuous duty. That works out to just about 202 days, based on 8 hours per day performance, the coated vibrators, running without any type of lubrication have been running about 4.7 times longer than the standard unit! Certainly, the testing has shown the benefit of the coating material. From the start of the test, while it would have been hard to predict how long any of the vibrators would continue to operate without any lubrication, I’d never have predicted that ten months later both of the coated vibrators would be still operating.

We continue to run the vibrators to see if Super Blue will out last Super Grey, either way, both coatings are looking like super options for customers who need to run a pneumatic piston vibrator in a non-lubrication application. To learn more about our coated vibrators and the benefits of using them in your application, please contact a member of our Sales Team. As for the better coating, only time will tell.

UPDATE: After 2,664 hours, which is approximately 316 million strokes, the results showed that neither the Super Grey nor Super Blue coated vibrator failed prematurely. Both vibrators were able to start up and run every day of testing. Testing was completed when both vibrators accrued enough wear to the point that their force was diminished. However, due to the lower coefficient of friction and a thinner coating which produces less variance, we have switched our internal coating for continuous piston vibrators to the Super Grey. Due to the seals inside our Single Impact units, we still use the Super Blue coating which has shown to increase the longevity of the vibrator at a similar rate to the Super Grey coating.

Share this blog post:

Follow us: