Are you looking to add a vibratory compaction table to your facility’s manufacturing and shipping processes? If yes, great! We’d be glad to help put our experience to work and point you in the right direction. There are a few things to review during the buying process, each of which can impact the equipment’s overall cost.

For starters, what can a vibratory compaction table do? We commonly see the following reasons to include a table:

- Flatten the mound build-up, or pile, of material made from the filling station discharging into the center of the Gaylord, tote, box, or similar type packaging container

- Compact and stabilize bulk bags, FIBCs, or super sacks for easier stacking and handling before storage or shipment

- Fully or semi-automate packaging lines by integrating with rollers sections (CDLR and gravity) or belt conveyors

- Fill, weigh, and compact material

- Remove air bubbles in molds and cast products for improved structural and surface finish

- Lower labor hours and costs for packaging and processing lines

Next, let’s look at some items to consider when costing the project before ordering the capital equipment. There are different aspects of the vibrator table designs that account for various portions of the purchase price:

Where am I installing this vibratory compaction table in my process?

What kind of surface does my application require?

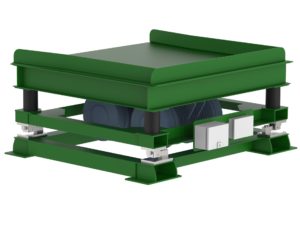

Flat decks (FA Models) are designed with a contact surface that is a flat plate of steel. We then install air vibrators or electric vibratory motors installed underneath. For bag fill stations or container compaction applications requiring a low profile design, a flat deck fit with outboard vibrators makes a great space saver option. You can see this design featured in the video below.

Grid tops (GT Models) are designed with vertical grids that raise above and lower below the roller section (CDLR or gravity). The table integrates into automated or semi-automated packaging and filling processes. You can see this model being used in a concrete settling and de-airing application in the video below.

Belt tables (BT Models) are designed with a flat deck vibratory table model built underneath the belt conveyor. The construction of these tables allow for vibrating and conveying simultaneously. The BT Model is ideal for applications that require gentle vibration to remove air pockets in molds or flatten bags before palletizing. Think of your favorite pet food for your pet. We bet that their food goes through a vibratory process before it reaches the shelves of your local pet store using a piece of equipment like the BT Model.

See this piece of equipment in the video below.

What type of surface material does my application require for vibratory table construction?

Stainless steel costs can add up quickly. The material alone can be two to three times more expensive than mild steel. Our cost-efficient solution can make the product contact areas stainless steel while all other components are mild steel. Another option is to use mild steel and finish the exterior with a corrosion-resistant coating.

What kind of power supply does my application need?

Pneumatic power typically uses our VMSAC Air Cushion Piston Vibrators. We manufacture these units here at Cleveland Vibrator. This is an economical option for applications that take place in hazardous environments. However, this power supply is limited to lighter design loads, usually around 2,000 lbs. max load capacity.

Electric power uses RE Rotary Electric Vibrators for more demanding applications involving much larger max load capacities. The Rotary Electric Vibrators can handle up to 20,000 lbs. or more, giving the user the independent control to adjust the force and frequency for their application. However, this does require a higher price commitment for the investment of the piece of equipment.

What are the isolation package options for my vibratory table?

- Coil springs are the most versatile and economical but can be noisy. These are compatible with all frequencies.

- Marsh mellow mounts are great isolators but ineffective for equipment with high-frequency vibrators (we suggest 1800 RPM/VPM or lower).

- Airbag isolators are, from our experience, the best isolation package available. However, this option is also the most expensive and requires air power to operate correctly. But, these are necessary for the grid top designs to allow the raising and lowering of the vertical grids to get above or below the top of roller height. As an added safety feature, these can also be programmed into the vibratory controls package to prevent vibration from turning on when the airbags are not inflated.

Does my application require load cell or weighing capabilities?

If necessary, we apply load cells in a vibratory table design to help with semi-automatic or fully-automatic packaging and processing lines. These load cells are isolated from the vibration and installed under the supporting legs of the flat deck, low profile flat deck, grid deck, or low profile grid deck table designs. When integrating the load cells into the vibratory table, we can provide a control package to communicate between the load cell modules, vibratory motors, fill device, and CDLR roller sections.

Lastly, when compiling the list of “must-haves” with the vibratory table equipment, these items listed all impact the equipment’s performance along with purchase price and required maintenance during operation. For an example, let’s take a look at some budget numbers of two units for a similar application – 48″ x 48″ flat deck table designed to compact and stabilize a 1000 lb bulk bag underneath a filling station:

Air-powered vibratory compaction table with the following options:

- Low profile deck design

- Mild steel construction

- Air-powered vibrators with solenoid valve control package

- Coil spring isolators

- No-load cells

Total Budget Price – Between $5,000 and $8,000

Electric-powered vibratory compaction table with the following options:

- Low profile deck design

- Mild steel construction

- Vibratory motor controls package for on/off, frequency adjustment, and quick stop (dynamic brake)

- Marsh mellow isolators

- Load cells control package to integrate with the fill station (fast and dribble fill settings), load cell modules and vibratory motors

Total Budget Price – Between $20,000 and $25,000

The more automated the equipment, to higher the price tag. Unfortunately, that comes with the territory. However, increasing automation results in a decrease in labor hours to get the job done. This benefit is something to consider when looking at this type of equipment.

Remember, these are rough numbers and can vary when sizing the project for your needs. Hopefully, this helps give some idea of what to expect and what to consider when exploring adding a vibratory table to your facility’s production or packaging line. Please contact our team for more information or one-on-one consulting for your project. We’re happy to help!

Mike joined The Cleveland Vibrator Company team in 2013 with prior experience in manufacturing sales with a Cleveland company in the tool and die industry. Now, he’s the Director of Sales and specializes in “making stuff that shakes stuff”.

When he’s not immersed in the world of industrial vibration, as rare as that might be, Mike keeps busy *not finishing in last place* in Fantasy Football and enjoys spending time with his wife and three kids. It’s always golf season for Mike, and he’s been known to 3 putt his way around any course and can roll tee balls in rain or shine. You can find him tailgating in the Muni Lot before Browns games or supporting local breweries.

As an avid provider of #VibrationEducation, he offers this free bit of advice, “Not all vibration is the same. Force and frequency do matter!” However, there is a 2% upcharge for all Michigan and Steeler’s fans.

Share this blog post:

Follow us:

2 Responses to Vibratory Compaction Tables: 5 Things to Consider When Working Within A Budget