When it comes time to review solutions to the material flow problems inside the hopper, pipe, or chute, there are a few things to keep in mind when putting together a budget for the project. Besides the vibratory flow aid itself, there are additional components required before installing the unit. We will discuss these items and estimated costs of acquiring these components. Here is the shortlist:

- Industrial vibrator – pneumatic piston vibrator, single impact air knocker, pneumatic turbine vibrator, pneumatic ball vibrator

- Safety cable

- Mounting channel or plate

- Hose to connect the vibrator to the on/off valve

- On/off valve

- Hose to connect on/off valve to air prep component (filter/regulator or filter/regulator/lubricator)

- Lubricant (if necessary)

Depending on the size of the hopper or piece of equipment that the pneumatic vibrator is going to be installed on, the price of the vibrator itself can range from about $100 to as much as $10,000. But, within that range, the vast majority of the units are going to be between $100-$1000.

The safety cable assembly size is dictated by the size of the vibrator it is going to need to support. This is an added safety item that reduces the risk of injury to an employee, damage to other equipment or plant floor if something were to happen that would cause the vibrator to break loose from the mounting channel or plate. These items are between $25-75.

The mounting channel size, length, and thickness are dependent upon the vibrator and the bin, hopper, or whatever it is being stitch welded to. The Cleveland Vibrator standard SMP series mounting channels, which come with drilled holes for the vibrator base mounting, ground smooth surface for a flush fit with base gasket supplied with the piston vibrators or air knockers, and a support rib in the middle to increase the rigidity of the channel and allow for the channel itself to absorb more impacts from the piston. These items are anywhere from $50 to $450 but the majority of the units are shipped out the door at $150 or less.

The mounting channel size, length, and thickness are dependent upon the vibrator and the bin, hopper, or whatever it is being stitch welded to. The Cleveland Vibrator standard SMP series mounting channels, which come with drilled holes for the vibrator base mounting, ground smooth surface for a flush fit with base gasket supplied with the piston vibrators or air knockers, and a support rib in the middle to increase the rigidity of the channel and allow for the channel itself to absorb more impacts from the piston. These items are anywhere from $50 to $450 but the majority of the units are shipped out the door at $150 or less.

The hose sizes are also dictated by the vibrator, specifically the inlet air connection to the vibrator itself. Along with the length and size of the hose, the type (e.g. neoprene, stainless steel braided, etc.) has an impact on cost as well. Cleveland Vibrator supplies neoprene hoses with brass fittings as a standard. The common length is 5 ft. but other options are available. These items typically range from $30 to $100, depending on what is required.

The on/off valve can vary in size and type. The vibrator size determines the NPT size of the valve and the installation location dictates what is required from the valve in regards to the power supply (e.g. manual or solenoid). The type of vibrator also tells the story about which type of valve is required. For example, the air piston, turbine, and ball vibrators can be operated with a 2-way, normally closed valve. There is an exhaust port on the vibrator body so a 3-way valve is not needed for operation. The single impact air knocker units require a slightly different type of valve. They need a 5-port, 4-way, 2-position valve to control the impact and return stroke of the steel piston inside the casted body. The costs of the 2-way valves can range from about $100 to $200 while the cost of the 5-ported, 4-way valves, which also come with all adapters and fittings for proper port size for operation and an adjustable speed muffler to slow down the return stroke of the piston, range from $500 to $2000. Most units are between $500 and $1000, depending on the size of the air knocker.

The air prep components change based on the vibrator being installed. The air piston vibrators and single impact air knockers require the filter/regulator/lubricator combo while the turbine vibrators are only required to be operated with the filter/regulator because of the permanently sealed and greased bearing inside the unit which allows for lube-free operation. The ball vibrators can be operated with both the filter/regulator/lubricator and the filter/regulator. Lubrication is not necessarily required for the ball vibrator but it will extend the life of the unit. These air prep components are typically between $75-$200.

The air prep components change based on the vibrator being installed. The air piston vibrators and single impact air knockers require the filter/regulator/lubricator combo while the turbine vibrators are only required to be operated with the filter/regulator because of the permanently sealed and greased bearing inside the unit which allows for lube-free operation. The ball vibrators can be operated with both the filter/regulator/lubricator and the filter/regulator. Lubrication is not necessarily required for the ball vibrator but it will extend the life of the unit. These air prep components are typically between $75-$200.

Lastly, the lubricant, if necessary. For all of the Cleveland Vibrator products that are required to be lubricated, we suggest Vibra-Lube. The Cleveland Vibrator Vibra-Lube is a 10W/NR oil. This lubricant is available in various size containers and costs are between $25-200 depending on the amount of lubricant provided.

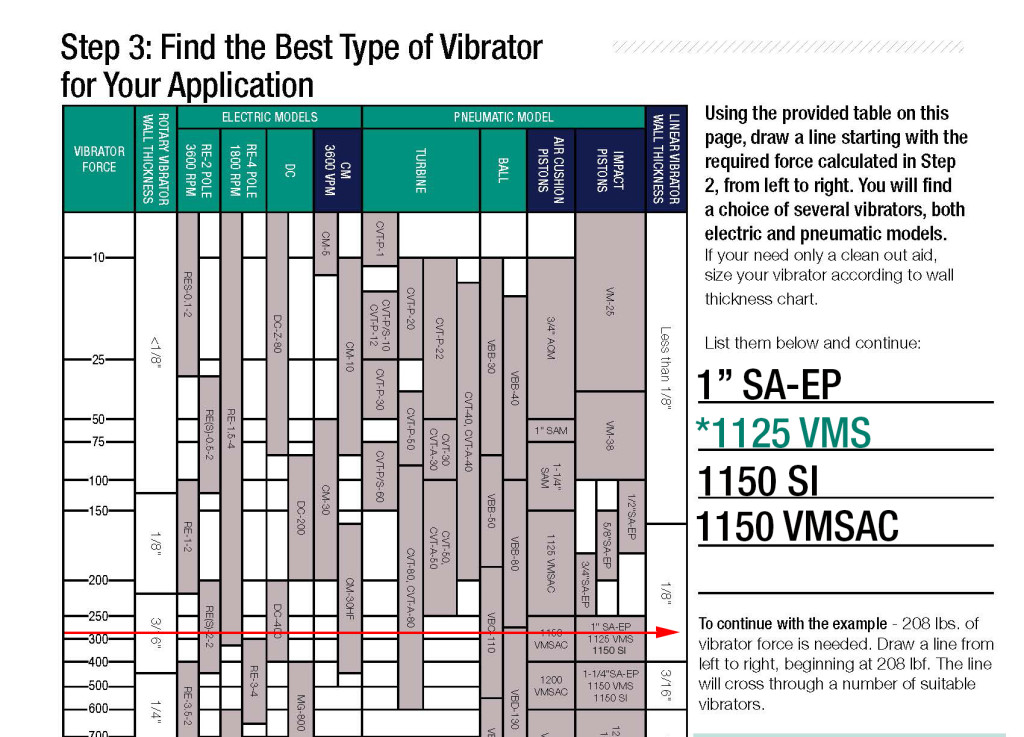

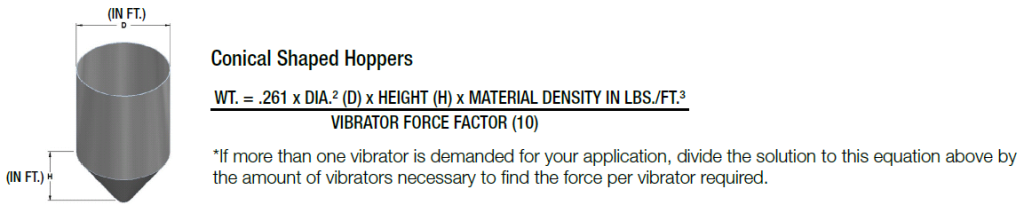

To help put things in perspective, let’s look at an example. Let’s say you are looking for an impacting air piston vibrator for your bridging sand or cement mix in the hopper. Let’s assume, for the sake of conversation, that these materials are about 100 lbs/ft^3 and, the dimensions of the bin are 6 ft. diameter conical silo with a 2 ft. tall transition hopper at the bottom of the silo with 1/8” thick mild steel used for the construction of the hopper walls. Using the Cleveland Vibrator Selection Guide, we are able to determine which size of air piston vibrator would be required and thus the associated components of the kit as well.

D = 6 ft

H = 2 ft

Bulk density = 100 lbs/ft^3

We estimate that the vibrator will need to generate about 280 lbs of force. Looking at the selection guide and confirming that this impacting air piston vibrator will be installed on an 1/8” thick hopper wall, the 1125 VMS model would be the recommended vibratory flow aid to be installed.

Now, let’s look at some estimated costs associated with this item:

- Vibrator – $150 to $200

- Safety cable – $25

- Mounting channel – $50

- Hoses – $50-100

- Valve – $75-150

- Air prep components – $100

- Lubricant – $25-50

Depending on the items required, putting together this kit for installation will typically range between $400-600. Hopefully, these tips will help you the next time you are looking to add a vibratory flow aid to a bin or hopper and break up the ratholing, bridging, or sticking material.

If you have questions about an application or an installation, please feel free to contact the Cleveland Vibrator team at any time. We are always glad to help!

Mike joined The Cleveland Vibrator Company team in 2013 with prior experience in manufacturing sales with a Cleveland company in the tool and die industry. Now, he’s the Director of Sales and specializes in “making stuff that shakes stuff”.

When he’s not immersed in the world of industrial vibration, as rare as that might be, Mike keeps busy *not finishing in last place* in Fantasy Football and enjoys spending time with his wife and three kids. It’s always golf season for Mike, and he’s been known to 3 putt his way around any course and can roll tee balls in rain or shine. You can find him tailgating in the Muni Lot before Browns games or supporting local breweries.

As an avid provider of #VibrationEducation, he offers this free bit of advice, “Not all vibration is the same. Force and frequency do matter!” However, there is a 2% upcharge for all Michigan and Steeler’s fans.

Share this blog post:

Follow us:

2 Responses to What Are the Costs Associated with Installing Pneumatic Vibrators?