Have you ever had someone try to push you over from your side? I recall skiing with my big brother once when we were kids. We had gotten off the chair lift and were stopped at the top of a run, getting ready to head down. I was standing with skis closely together in parallel, hands off my poles as I adjusted my goggles. Big brother gave me a push on my shoulder from the side, perpendicular to the direction of my stance and skis. I tipped right over. There was nothing I could do about it. It was hilarious… at least it was to him and everyone watching me flail about wildly on my way down. Had I positioned my skis and stance wider and center of gravity lower, I could have avoided this embarrassing failure.

Such is as it is with Rotary Electric Vibratory Motors. Imagine for a moment that you have a long bar going right through your solar plexus and out of the middle of your back. Now that you are over that painful thought, imagine that at each end of the bar, there is a weight dangling from a rope and swinging around that bar. Those weights are pushing you in every direction perpendicular to your feet and stance. You are now a Rotary Electric Vibrator! Can’t quite get the mental picture? Check out the photo to the right to see what I am talking about.

This brings up some great considerations for construction features to review when choosing Rotary Electric Vibrators for powering your Vibratory Equipment or as a material flow aid for a bin, hopper, chute or pipe. How would you want to be built in order to maintain stability while managing the forces of those swinging weights and not fail embarrassingly as I did on my skis so many years ago?

In a nutshell, you would want to be short and wide! Furthermore, you would sure want that pole sticking through you to be as short and thick as possible so that it is stable and unbending.

This concept translates to 4 easily measured, dimensional construction features to compare when looking to choose Rotary Electric Vibrator:

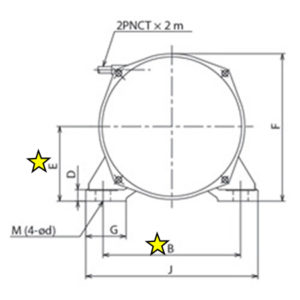

1: Width – Width equates to the concept of having a “wide stance.” In the diagram to the left, that would be dimension “B,” which is the distance between bolt holes across the vibrator and in-line with the plane of the forces being thrown.

2: Height of Center of Gravity (CG) – While considering the “wide stance,” the other dimension to really compare stability is the height of the center of gravity, which should be the location of the motor shaft holding the rotating eccentric weights. In the drawing to the left, this would be dimension “E.” When dimension “E” is less than or equal to “B,” the motor has a very stable base, similar to a triangle that is equilateral or obtuse.

3: Bolt Diameter – Another dimension to consider for showing the stability of the vibrator are the mounting bolt-hole diameters, which would be similar to strongly anchored feet in our metaphor. The larger diameter bolt-hole, the larger diameter bolt can be used, which gives the vibrator better anchors to what it is bolted. Now, some similar performance vibrators equal in force and frequency may use different numbers of bolt-holes, 4 instead of 6, for instance. In this case, you would want to consider the total bolt-hole area.

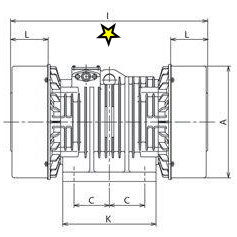

4: Length – A final dimension to consider would be the length of the shaft holding the spinning weights. Having moving weights on the end of the shaft will cause bending, or deflection, of the shaft. That deflection is not optimal for internal parts like the bearings holding the shaft, or the shaft itself. The more deflection, the less life out of these parts you can expect. So, the total length of the vibrator, dimension “I” on left, is a good indicator for how long and skinny or how short and fat the shaft is, with the shorter being better at reducing deflection.

So, when you are next choosing a Rotary Electric Vibratory motor for your equipment design, think about the direction or plane of the forces that the vibrator will produce and therefore need to handle. Check how Width, Height of CG, Bolt-Hole Area, and Length compare between brands with models meeting Force and Frequency needs for your application. Lastly, see if you can identify any options that stand out as clearly advantaged or disadvantaged before checking further comparisons. For any help or further info, don’t hesitate to contact us here at Cleveland Vibrator.

Craig Macklin joined The Cleveland Vibrator Company in 2010. Although his prior experience is mired in the world of theoretical, intangible products and services such as software and consulting sales, the past 11 years have developed his passion for this industry and molded the vibration expert we know today. Now, as President and CEO, Craig has a deep understanding of the value and importance of industrial vibration to numerous industries and applications. He enjoys fine, locally roasted espresso, good food, and spending the day with his wife and two daughters. He has cried at multiple Browns and Indians games and likes to get outside and golf in his free time.

What’s his area of expertise, you ask? “Making sure the people on our team are better and smarter than I am.” – Craig Macklin

Share this blog post:

Follow us: