Over the years, I have read many articles about how to reduce fine mesh screen blinding on vibratory screeners. These solutions range from polyurethane balls to brushes. One of our most frequently asked questions is how to clean screens once they are blinded for fine mesh applications. Some customers simply throw out the blinded screens or send them back to our rescreening department for a new screen to be applied.

How to Clean Coarse Mesh Screens

A screen does not necessarily have to be a very fine mesh in order to blind. We have seen screens with a mesh as coarse as a 2 or 3 mesh easily blind due to product lodging in the openings while conveying across a screen deck. Of course, the larger the mesh opening the easier the screen is to clean. A larger opening can be cleaned from the “bottom-side” of the screen with a soft wire or hard nylon brush. We have touched on this type of screen deblinding in previous blogs. You can click here to read more about the solutions we suggest for these types of screening applications.

Options for Cleaning Fine Mesh Screens

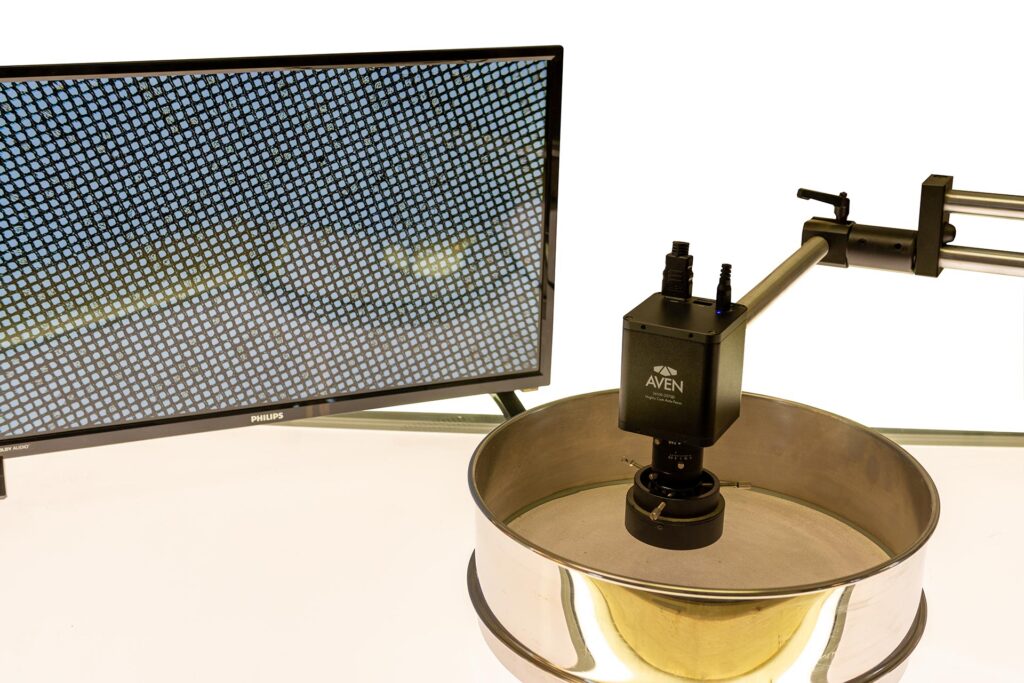

On finer wire mesh screens, let’s say 200 mesh and finer, a soft bristle brush may work, but you risk tearing the screen surface. Worse yet you could cut the fine wire mesh, turning the 200 mesh opening into a much larger-sized opening. If your screen frames are small (3”, 8”, 10”, 12”) there are reasonably priced ultrasonic baths that are very effective in cleaning the hardest material from the mesh apertures. Another more cost-effective method is pressure washing the screen surface from the bottom side of the screen surface. Essentially forcing the dislodged material back out of the screen apertures. From our experience, don’t place the pressure washer tip too close to the screen surface. Trust me, you will easily blow a hole through your screen!

It May Be Time to Rescreening When…

Some material may melt to your screen surface if it gets too hot or there is too much material build-up. If this is the case, such as with powder coatings or some nylon materials, we will use solvents to easily clean the screen surface. Simply submerge the fine mesh screen in a bath of solvent and give it some time to dissolve or soften the material. Then there are some of the extremely stubborn or impossible-to-remove materials like ones that tend to be jagged type materials. This could include hammer-milled materials. Unfortunately, for some materials, there is no hope of cleaning the screen.

Inspect the screen for sagging or any small holes or tears if the screen has been cleaned numerous times. We suggest purchasing a new screen frame or getting them rescreened If any of these issues are observed. In some cases, a new screen may be necessary. However, if the frame is in good condition, rescreening your old frame will save you 30-40% of an entirely new screen frame.

Do you have old fine mesh screens in need of rescreening? HK Technologies offers a full rescreening service, even if the screens didn’t originally come from us. Contact us today to learn more.

Jeff Hochadel has over 25 years of experience building and selling vibratory screening equipment. Jeff is responsible for handling fine mesh screening applications for The Cleveland Vibrator Company. His expertise is utilizing our Ultrasonic Deblinding System to solve difficult screening problems. When Jeff is not visiting customers promoting our products you can most likely find him fly fishing.

Share this blog post:

Follow us:

2 Responses to How to Properly Clean Fine Mesh Screens Without Damaging Your Equipment