The Cleveland Vibrator Company started manufacturing air-operated vibrators in 1923 and for several years air vibrators are all we pretty much offered. This worked well in our primary foundry customer base through the first half of the 20th century. As we expanded our customer base, we found more and more customers wanting to use electrical power to operate the industrial vibrators. It became obvious that we needed to give our sales staff an alternate source besides air to offer our valued customers.

We started with fairly basic electromagnetic vibrators with the MC-1, MC-2, etc. and started to introduce these units into the marketplace. The MC series is considered the “grandfather” to our current CM-5, CM-10, and CM-30 and more recent Super 30 vibrators. You can see a success story of this product in the field in the case study on the right-hand side of this paragraph. In the early ’60s, we contracted with a company from Sweden called Dynapac to market and sell their rotary electric vibrators mostly here in North America. They were supplied in 1800 RPM and 3600 RPM (revolutions per minute) which opened the door to customers having hoppers, bins, chutes, bunkers as well as other applications which include vibratory tables, feeder, and screeners.

We started with fairly basic electromagnetic vibrators with the MC-1, MC-2, etc. and started to introduce these units into the marketplace. The MC series is considered the “grandfather” to our current CM-5, CM-10, and CM-30 and more recent Super 30 vibrators. You can see a success story of this product in the field in the case study on the right-hand side of this paragraph. In the early ’60s, we contracted with a company from Sweden called Dynapac to market and sell their rotary electric vibrators mostly here in North America. They were supplied in 1800 RPM and 3600 RPM (revolutions per minute) which opened the door to customers having hoppers, bins, chutes, bunkers as well as other applications which include vibratory tables, feeder, and screeners.

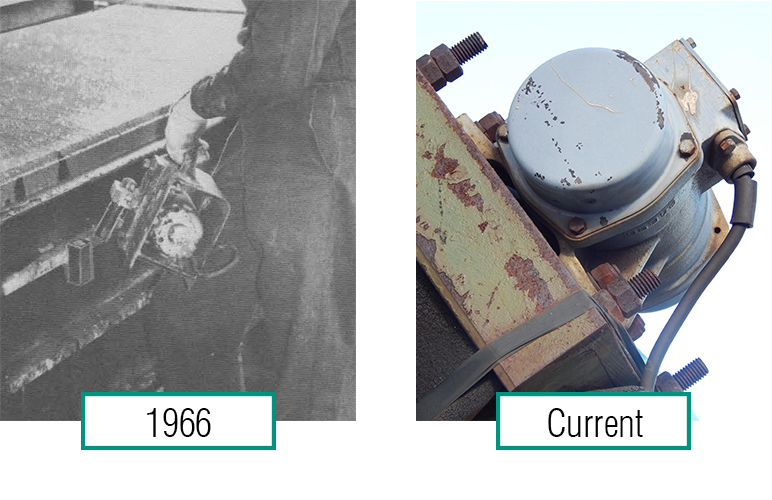

The idea that we could now offer two types of vibratory solutions for one application proved to be a great success. To the left, you will see an image of a case study from 1966. A burial vault company found that they did not have a sufficient supply of compressed air to operate a pneumatic powered vibrator to shake their burial vault forms. Using a UH style mounting head, they designed a bracket that was attached to a Cleveland Vibrator RC-2 Rotary Electric Vibrator model. The result? Satisfactory and trouble-free operation.

The idea that we could now offer two types of vibratory solutions for one application proved to be a great success. To the left, you will see an image of a case study from 1966. A burial vault company found that they did not have a sufficient supply of compressed air to operate a pneumatic powered vibrator to shake their burial vault forms. Using a UH style mounting head, they designed a bracket that was attached to a Cleveland Vibrator RC-2 Rotary Electric Vibrator model. The result? Satisfactory and trouble-free operation.

However, there was a little bit of “catch-22” in our new product line. All of the rotary electric vibrators offered were single voltage units, so it was important to know what our customers needed. What was even more difficult, in my opinion, was trying to place an order for rotary electric vibrators and try and cover all the voltage requirements knowing the lead time was several weeks out from order point to the actual receipt of drives.

It had turned into an inventory control, purchasing, and sale challenge just to try and keep the correct voltage vibrators in stock or at least on order. We didn’t win all those battles but by far won more than we lost. Along with selling the Dynapac units, we decided from a “customer service, value-added standpoint” to also supply male and female power plugs for each vibrator. We quickly learned that, although it was a great idea, it was very difficult to keep up with the many different styles of power plugs used out in the industry. For example, we would ship a 460-volt vibrator with what we thought was the correct male-female plug assembly only to receive a call that it didn’t fit the customer’s receptacle. Typically, the problem was it wasn’t the right amps or the receptacle was different and wouldn’t accept the prongs on the male plugs. This went on for several years until we decided in some cases was doing more harm than good and discontinued this practice. Even with these challenges, it did improve our sales by giving our valued customers a choice between air or electric vibrators.

Around 1980 we were approached by another manufacturer of rotary electric vibrators named Yaskawa who was located in Japan. They offered us a wider range of vibrator forces including 3600 and 1800 RPM motors as well as 1200 and 900 RPM motors, previously not offered by Cleveland Vibrator. This allowed us to expand our feeders, screeners and vibratory tables business substantially. I believe over the past many years, the primary choice of vibratory motors for our equipment has become the 1200 RPM units or 6-pole as we most commonly call them. I am under the opinion that 1200 RPM motors give you a good vertical stroke when used on a vibratory table to fill containers. They also have a good enough stroke and RPM to be used on screeners not only to feed the material across the screen decks but also to separate it on the screen. On feeders, the six pole feed rate is good to feed most materials. This is not a “one size fits all” for industrial applications but it sure does cover several areas.

Around 1980 we were approached by another manufacturer of rotary electric vibrators named Yaskawa who was located in Japan. They offered us a wider range of vibrator forces including 3600 and 1800 RPM motors as well as 1200 and 900 RPM motors, previously not offered by Cleveland Vibrator. This allowed us to expand our feeders, screeners and vibratory tables business substantially. I believe over the past many years, the primary choice of vibratory motors for our equipment has become the 1200 RPM units or 6-pole as we most commonly call them. I am under the opinion that 1200 RPM motors give you a good vertical stroke when used on a vibratory table to fill containers. They also have a good enough stroke and RPM to be used on screeners not only to feed the material across the screen decks but also to separate it on the screen. On feeders, the six pole feed rate is good to feed most materials. This is not a “one size fits all” for industrial applications but it sure does cover several areas.

With adding the new RPM models, this was a good reason to make a change to Yaskawa, now (Uras Techno), but there were other reasons to make the switch:

- Uras Techno was starting to produce dual voltage units in 230/460 three-phase, making the stock levels easier to control. It also helped our sales staff in selling the units in cases in which a customer needed 230 volts but ordered 460 volts, a change in electrical leads could be made in the field and not require the units to be returned.

- The mounting of the vibrators used standard bolts and locknuts unlike most of the vibrators from Dyanpac, requiring a special u-shaped mounting bracket. In our catalogs, we called them out as EB and HEB mounting brackets.

- The new vibrators came with a 6-foot power cord attached.

- Uras offered vibrators in 50 and 60 cycles plus 380 and 575 volts and we now have the CSA approval on all the 575-volt units for our Canadian customers as well as a CE certification option that is mostly used in Europe.

These features and options allow The Cleveland Vibrator Company to service  our worldwide customer base in a more efficient manner. The air vibrators have and continue to be the core of our business and are still manufactured here in Cleveland, Ohio. By adding the electric vibrator line, we now offer our valued customer two types of vibrators with different power sources for the same application. We are able to ask if the customer prefers or requires air or electric for their application. If you review the wonderful new vibrator selection guide we published in 2016 (link to this document available by clicking on image to the right), you will find the air to electric comparison but if you need further clarification, you can call and or e-mail our experienced sale staff to assist you. When you add in our vibratory equipment and fine material sifting division, Cleveland Vibrator becomes your one-stop-shop. Ninety-three years in the business and we must be doing something right and I believe that is summed up in two words: “CUSTOMER SERVICE”. -Glen Roberts

our worldwide customer base in a more efficient manner. The air vibrators have and continue to be the core of our business and are still manufactured here in Cleveland, Ohio. By adding the electric vibrator line, we now offer our valued customer two types of vibrators with different power sources for the same application. We are able to ask if the customer prefers or requires air or electric for their application. If you review the wonderful new vibrator selection guide we published in 2016 (link to this document available by clicking on image to the right), you will find the air to electric comparison but if you need further clarification, you can call and or e-mail our experienced sale staff to assist you. When you add in our vibratory equipment and fine material sifting division, Cleveland Vibrator becomes your one-stop-shop. Ninety-three years in the business and we must be doing something right and I believe that is summed up in two words: “CUSTOMER SERVICE”. -Glen Roberts

Share this blog post:

Follow us: