Generally speaking, in life, choices are a good thing. This applies to industrial vibrators and vibrating equipment as much as it does for lunch time options. In terms of fabricated vibratory equipment, Cleveland Vibrator offers a variety of solutions to processing and material handling problems. Regardless if the need is for a vibratory feeder, screener, compaction table or vibratory belt table, our sales and application folks are up to the challenge of solving the particular needs and requirements of our diverse customer base. As I mentioned in earlier blogs, when it comes to vibratory equipment, one size in fact doesn’t fit all. Rarely do one customer’s particular requirements match up exactly with another customer’s, the solution may be similar in type but not in exact physical size. Tailoring to meet the individual needs of each customer is part of the Cleveland Vibrator fabricated equipment DNA.

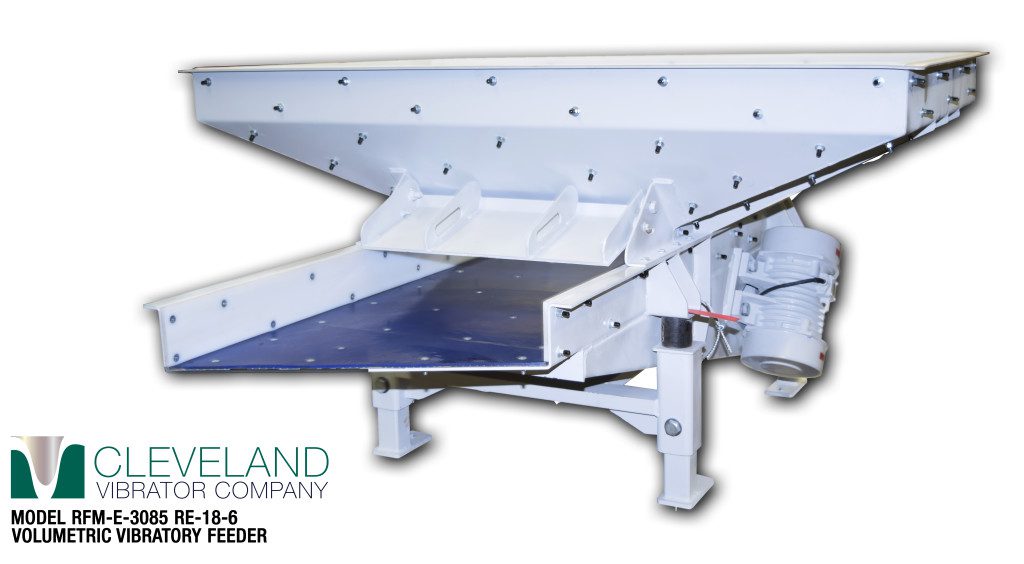

One of the many types of fabricated equipment manufactured by The Cleveland Vibrator Company is the volumetric feeder. Internally, they are generally referred to as Hopper Feeders, RFM, these units can be pneumatic or electric powered. The key design element is that a vibratory feeder has a storage hopper associated with it which accepts and stores dumps of material and then feeds the material out of the hopper in a controlled manner. These units might be as small as a lab sized unit with a 1.5 cubic foot hopper capacity with a 1-1/2” wide vibratory tray driven by an 1125 VMSAC air cushioned pneumatic vibrator, to large electric powered units with 4-5 foot wide feeding surfaces and hoppers with capacities in excess of 80 cubic feet which might utilize twin Rotary Electric (RE) vibrators such as the RE 24-4. A small hopper-feeder with a four inch wide tray can be seen in operation by following this link to The Cleveland Vibrator Youtube channel.

From an engineering standpoint, the design of the hopper-feeder falls into two broad categories, units with a vibrating or a non-vibrating hopper. After that we’d break it down a bit further and we look at the source of vibration, pneumatic or electric. I’d like to talk a bit about the pros and cons of the hopper arrangement, attached (vibrating) and unattached (non-vibrating).

While we do design and manufacture both configurations, I think we tend to see more of the attached hopper arrangements. In the attached design, the storage hopper is mounted directly to the vibratory feeder and then the combined two part assembly is isolated from the base support. With this set up, the energy of the vibrators is input into the feeder which in turns vibrate the “feeder” tray and the hopper. One of the advantages to this arrangement is that whatever is in the hopper is also being vibrated and actually fed out of the hopper and on to the next step in the customer’s process. The physical vibration of the hopper virtually guarantees whatever is in the hopper will move out of the hopper and down the feeder conveying surface. This forced movement allows for lower profile hoppers with more shallow angled walls than would be normally permitted and still deliver dependable movement of parts/materials from the hopper.

The low profile hopper is certainly beneficial when customers have height limits due to surrounding processing equipment or limitations on the equipment dumping parts into the hopper. A number of our customers who process small parts such as fasteners or stamping billets typically use the combined hopper-feeder design, seeing the benefit for the lower profile and confidence that all parts will exit the hopper. An empty hopper at the end of a cycle is particularly important when multiple parts are run through the unit and there’s concern of cross part contamination.

The only drawback to the combined unit design is that it requires somewhat larger vibrators than would be required for a non-vibrating hopper. Since the hopper is now part of the vibrating structure, the material weight of the hopper has to be considered when sizing the vibrators. Additional moving mass requires a larger set of vibrators to achieve the desired feed rate. It seems that most customers see a benefit from this design and the slight increase in the cost of the unit due to the larger vibrators isn’t a major concern. You can see this type of unit in action on our YouTube Channel.

Units designed with a non-vibrating hopper have many of the same performance characteristics of their vibrating hopper brethren. Material can be dumped into the hopper, the constant supply of material helps provide an even and controllable flow of material. Batching of loads can be performed; material is metered out and fed downstream at a rate that works with other equipment or processes. Given a properly designed hopper, material will effectively move from the storage area of the hopper onto the vibrator feeder and off the end of the feeder tray.

The same hopper-feeder design can be applied to hopper-screener type units. Similar design arrangement but the material is screened as it exits the hopper. We recently delivered a hopper screener to a customer that wanted a portable unit. Due to a combination of design requirements:

- Loading the unit via a front end loader

- Height of the hopper low enough so that operators standing on the ground could look into the unit

- Input power limited to single phase 110VAC, Cleveland Vibrator designed and manufactured a unit with a non-vibrating hopper but due to the wide low profile of the hopper an external vibrator was added to the back of the hopper to aid in the flow of the material

The frame of the unit which supports the hopper and the screener was then mounted on casters to permit easy movement around the customer’s facility. By using the non-vibrating hopper design, the vibrating weight of the unit was low enough to allow for the use of smaller vibrators which could be powered by a variable frequency controller which accepts 110VAC input power and outputs 230/3/60 power to the vibrators. This unit can also be viewed in the following video on Cleveland Vibrator’s Youtube Channel.

Hopper-feeder and hopper-screen units can include options such as abrasion resistant liners, either steel or polymer materials. Urethane liners are also available to help with noise reduction and increased protection from impact damage as parts and material are dumped into the hopper.

Whether it’s a hopper feeder or a hopper screener, these units offer many advantages and can solve a variety of material handling problems. Based on the end user’s requirements, CVC can design the appropriate solution. For additional information please contact one of The Cleveland Vibrator Company’s Sale Team members.

Follow us:

Share this blog post: