The Cleveland Vibrator Company has been manufacturing pneumatic piston vibrator units since 1923. Over the past 90+ years, we have learned a few things about how to protect your investment in an air piston vibrator. There are a few main procedures and components we strongly suggest and will review:

- Air Supply

- Exhaust Ports

- Gaskets

The air supply should be dried and filtered, then regulated and once between 0-80 PSI, the air should be lubricated. We have Watts Filter-Regulator-Lubricators available ranging in size for 1/4″ to 1-1/”4 NPT. Glycerin filled regulator gauges help to read the PSI setting easily. Lightweight 10W/NR oil should be dropped into the airline prior to reaching the vibrator. We have pints of Vibra-Lube available to help save the search for this type of oil.

The air supply should be dried and filtered, then regulated and once between 0-80 PSI, the air should be lubricated. We have Watts Filter-Regulator-Lubricators available ranging in size for 1/4″ to 1-1/”4 NPT. Glycerin filled regulator gauges help to read the PSI setting easily. Lightweight 10W/NR oil should be dropped into the airline prior to reaching the vibrator. We have pints of Vibra-Lube available to help save the search for this type of oil.

These TLC steps can double or triple the air piston vibrator’s life expectancy. Our dual-diameter piston design allows for start-up in any mounting position (e.g. at 30° on a vibratory feeder or 60° angle on a hopper or 90° on a vibratory table) and eliminates the need for a spring. The springless unit keeps replacement parts and internal components to a minimum. So, with a proper air supply plumbed to the vibrator and a low number of wearable parts, these units can last a long time and return the money on your investment.

The other half of the equation is the vibrator itself. There are a few areas where we take a few extra steps in our manufacturing process to help our customers increase their chances of having the vibrator last a long, long time. Because of these steps, we have a large number of vibrators in the field that have celebrated their 10th birthday. These steps are:

Cap Gaskets – These standard features on the vibra-mite line (e.g. SI, VMS, VMSAC, VMR, VMRAC, VMRR) of air piston vibrators benefit the user by promoting longevity of the vibrator. The cap gasket is between the steel cap and the casted body that are bolted together using grade 5, fine thread, hex head cap screws (HHCS) and lock washers. This gasket seals the connection point between the cap and the body blocking contamination and other foreign matter from entering the unit. High temperature gaskets should be considered, and are available, for areas with ambient temperatures warmer than 250°F (120°C). Consult our team for options in warmer working environments.

Cap Gaskets – These standard features on the vibra-mite line (e.g. SI, VMS, VMSAC, VMR, VMRAC, VMRR) of air piston vibrators benefit the user by promoting longevity of the vibrator. The cap gasket is between the steel cap and the casted body that are bolted together using grade 5, fine thread, hex head cap screws (HHCS) and lock washers. This gasket seals the connection point between the cap and the body blocking contamination and other foreign matter from entering the unit. High temperature gaskets should be considered, and are available, for areas with ambient temperatures warmer than 250°F (120°C). Consult our team for options in warmer working environments.

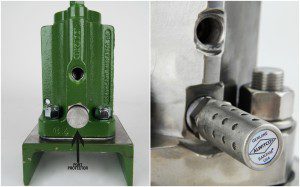

Base Gasket – The base gasket is installed between the base flange of the casted body of the vibrator and the mild steel or stainless steel mounting channel. Every vibrator we ship comes with grade 5, fine thread, mounting fasteners and ESNA lock nuts. This gasket helps seal the connection point between the stitch welded mounting channel on the equipment and the base of the vibrator.

Base Gasket – The base gasket is installed between the base flange of the casted body of the vibrator and the mild steel or stainless steel mounting channel. Every vibrator we ship comes with grade 5, fine thread, mounting fasteners and ESNA lock nuts. This gasket helps seal the connection point between the stitch welded mounting channel on the equipment and the base of the vibrator.

Exhaust Port Protector – The Exhaust Port Protector helps prevent dusts and other foreign matter in the operating environment from entering the bore of the vibrator. This aluminum component comes with rubber o-rings installed. The o-rings protect the opening while the vibrator is off and move out of the way when the vibrator is operating so that the air to escape from the Exhaust Port Protector itself. We do have mufflers available in zinc plated steel and in stainless steel.

Another exhaust option, if exhausting air in the area is against operating environment safety regulations, is to pipe the exhaust away. This can be done with a neoprene hose, which we have available, or plastic air line connected to a push-to-connect fitting (we have fittings available that can be supplied upon request to be a replacement for the Exhaust Port Protector at no charge).

Another exhaust option, if exhausting air in the area is against operating environment safety regulations, is to pipe the exhaust away. This can be done with a neoprene hose, which we have available, or plastic air line connected to a push-to-connect fitting (we have fittings available that can be supplied upon request to be a replacement for the Exhaust Port Protector at no charge).

Why should these steps be taken? Due to the tight tolerances between the outside diameter of the piston and the inside diameter of the casted body, the internal section of the vibrator needs to be clean of foreign matter. This includes, but is not limited to, small particles from the working environment, dust from the surrounding area, miscellaneous contaminations in the air supply line that is powering the vibrator. If there is anything between the bore of the casted body and the steel machined piston, problems can occur.

Most common problem is the seized piston. The main reason this happens is when a piece of foreign matter is stuck between the piston and the casting causing the piston to freeze. This foreign matter rubs between the two internal components and caused the coefficient of friction is increased greatly. This friction limits or stops the piston from moving and, in turn, prevents vibration energies.

By taking a few steps, the user of the Cleveland Vibrator air piston vibrator can expect to have the unit in operation for an extended period of time. We take pride in our manufacturing process, every step of the way, and it shows in the quality of the end product.

We are here to help and available to discuss applications or answer questions at any time. Please feel free to contact us.

Mike joined The Cleveland Vibrator Company team in 2013 with prior experience in manufacturing sales with a Cleveland company in the tool and die industry. Now, he’s the Director of Sales and specializes in “making stuff that shakes stuff”.

When he’s not immersed in the world of industrial vibration, as rare as that might be, Mike keeps busy *not finishing in last place* in Fantasy Football and enjoys spending time with his wife and three kids. It’s always golf season for Mike, and he’s been known to 3 putt his way around any course and can roll tee balls in rain or shine. You can find him tailgating in the Muni Lot before Browns games or supporting local breweries.

As an avid provider of #VibrationEducation, he offers this free bit of advice, “Not all vibration is the same. Force and frequency do matter!” However, there is a 2% upcharge for all Michigan and Steeler’s fans.

Follow us:

Share this blog post: