There are a wide variety of screening media that can be installed in vibratory screeners. Our challenge is to select which type would be best suited for your application. You can refer back to my blog: Importance of screening data from May 2013 to review the technical data that would best assist us in making screener recommendations. Some of this data would also be appropriate for selecting screening media. This blog is the first in a series that will be dedicated to typical screening media that are installed in Vibratory Screeners with their advantages and disadvantages so you can be in a better position to assist us in the selection process.

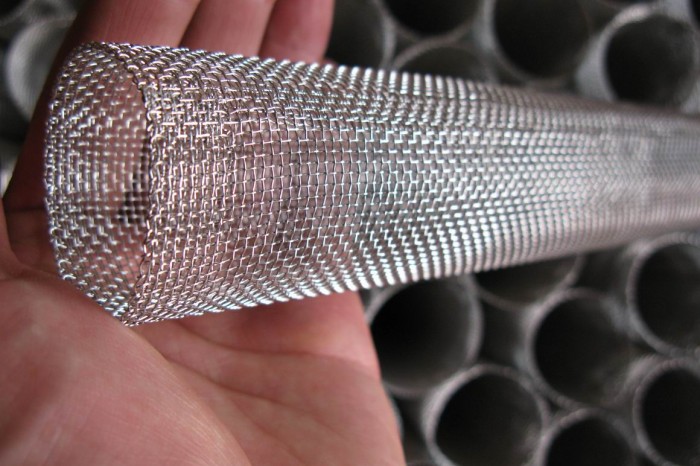

Woven Wire Cloth

This is the most common and widely used screening media for many applications including scalping, sizing and dewatering. Woven wire cloth is typically designated as space screen (clear openings) or square mesh. Space screen is the inside dimensions of the opening which should be further designated with a specific wire diameter. Please note that the wire diameter doesn’t affect the screen opening, but does affect the open area (percentage of opening space available in a screen section). Square mesh is the number of openings in one lineal inch measured from centerline to centerline of the diameter of the wires. Therefore, the same mesh could have several opening sizes available dependent on the wire diameter selected. For example, the openings will be smaller as heavier wires are selected.

Woven wire cloth is widely accepted for most screening applications. It is best suited for medium to fine screening and is available in the widest variety of metals with carbon steel and stainless steel being the most common. While square openings are the most common, it can also be supplied with slotted openings to provide more capacity and increased open area.

In short, here are the advantages of Woven Wire Cloth:

- It offers the largest variety of screen openings

- It has good open area

- The flexibility of the wires which can help facilitate the removal of fines and cost

- It is the most economical option for this type of screening application

It is important to note the disadvantages as well which include:

- They readily wear when handling abrasive materials

- The weaving of the wire creates “knuckles” which could impede the flow and/or cause some materials to hang up and the wires stretch

- The “knuckling” may call for the screen tension to be checked periodically and tightened as needed

In most cases the advantages far outweigh the disadvantages but in order to make a good decision about your best option, you need to have access to the knowledge to help in making an educated decision. That’s where we come in. You can now hopefully see why extremely versatile woven wire cloth was selected to kick off this series. Speaking of kick off, how bout those Browns! Stay tuned for information on other screening media (and hopefully Brown’s victories) to follow.

Photo Credit: http://www.steellong.cn/

Jack Steinbuch retired in 2021 following a decades-long career with The Cleveland Vibrator Company, where he served as a Sales Engineer for more than 36 cumulative years. His background also includes extensive experience in the manufacturing industry as a Senior Application Engineer, and throughout his tenure with our team he contributed in both sales and managerial roles. Prior to his retirement, he held the position of General Sales Manager.

A graduate of The University of Toledo with a BSCE, Jack is highly regarded for his expertise in sizing vibratory screeners, feeders, and vibratory drives for tables and other equipment. Known for his dedication to customer service, he has always emphasized the importance of recommending the right solution for every application — even when that solution did not come from The Cleveland Vibrator Company.

Outside of work, Jack enjoys spending time with his family, especially his grandchildren. An avid sports fan and participant, he enjoys golf and spent many winters as a league bowler. With his retirement planned for the end of September 2021, Jack looked forward to spending future winters vacationing in Florida.

Follow us:

Share this blog post: