Over the years I’ve received a number of requests for industrial vibrators or vibratory equipment that need to operate in a hazardous location. Most requests include the classifications they are either given or think they need, but often aren’t familiar enough with them to know what their application may really require. I believe, for vibrating motors especially, that most confusion stems from recognizing the difference between dust-tight and explosion-proof construction.

Our challenge for these applications is to clarify the classification being requested and offer possible alternatives to meet them. First, to my understanding, pneumatic powered drives are acceptable for any hazardous location. You only need to be concerned if you use an electrically activated valve to start/stop it, to make sure it meets the classification of the hazardous area.

There is a considerable amount of data for classifications, but I referred to an article that I felt handled the topic in a very informative manner. They started by defining the Class, or type, of material present as specified by NEC (National Electrical Code) and CEC (Canadian Electrical Code). Class I location is specified as a location containing flammable gases or vapors. Class II locations contain dust that is electrically conductive or could be explosive when mixed with air. Lastly, Class III locations contain easily ignitable filings and flyings.

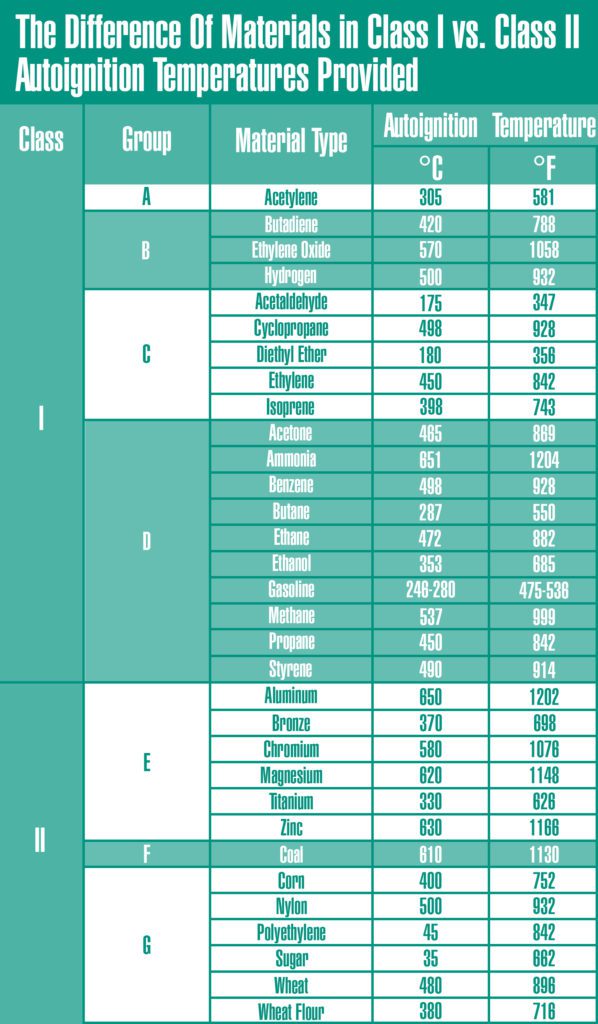

The hazardous materials found in Class I & II locations are further identified in Groups A, B, C, & D for Class I and E, F, & G for Class II. We have provided a chart for quick reference below for those interested in learning where your material falls categorically. More in-depth information about the group classification specifications can be found here.

The next part of the classification is division which “describes the conditions under which the material is present.” There are two divisions which can be described as follows: Division I conditions are classified as environments in which hazardous materials are present in the air during operations. Compare this to Division II conditions, where such hazardous materials are not present during normal operations.

Now comes the tricky part. Class I, Division I clearly requires motor vibrators to be explosion-proof construction. So the vibrator “must be constructed in such a way that it will be able to completely contain an internal explosion without rupturing”. So the motor vibrator “is not necessarily designed to prevent an explosion – only to confine an explosion within its housing”.

However, Class II, Division I “must be dust-ignition-proof”. So the motor enclosure needs to be designed to “exclude hazardous materials”. Therefore “explosive mixtures of particles in the air should never reach the inside of a dust-ignition-proof motor”. This would indicate a dust-tight motor.

Division II where hazardous material may only be present in an upset condition also doesn’t require the motor vibrator to be explosion-proof construction. An electric vibrator motor is acceptable in this area “provided it does not have arc-producing brushes or switching mechanisms, which could act as ignition sources”. Furthermore, the article notes the motor should have “sufficiently low surface temperatures and no sparking parts”.

So clearly identifying the hazardous material is imperative to selecting the proper vibrator motor. You may not require an explosion-proof vibrator motor. I’ve noticed more recently that there are more motors available that will meet the less stringent classifications where an explosion-proof vibrator motor is not required.

I hope this clears the air on explosion-proof drives for hazardous areas. Still have questions? We are here to help. Contact us today.

Amerom, U. V. (2011). Choose the Right Electric Motors for Hazardous Locations.

Retrieved from www.aiche.cep

Copyright © 2011 American Institute of Chemical Engineers (AIChE)

Jack Steinbuch has been with The Cleveland Vibrator Company for over 36 years accumulatively. He has previous experience in the manufacturing industry as a Senior Application Engineer and has worn many hats on our team in sales and managerial capacities. Now, he’s in the position of General Sales Manager. With a BSCE from The University of Toledo, he is an expert in the realm of sizing vibratory screeners and feeders, and sizing vibratory drives for tables and other vibratory equipment. Understanding that customer service is crucial, Jack believes it is important to provide the proper product for every application, even if it happens to not be supplied by The Cleveland Vibrator Company.

In his off-hours, you can find Jack spending time with his family and playing with his grandchildren. He loves sports; both watching and playing, and is an avid golfer and a league bowler during the winter. He will be retiring at the end of September 2021 and hopes to spend his winters vacationing in Florida.

Follow us:

Share this blog post: