Working for the Cleveland Vibrator Company, you can imagine how many times I get the question, “what exactly do you mean by vibrators?” It’s a question I answer with great pride and enthusiasm… and maybe add a little bit of humor for good measure. When I go on to explain just how important vibration is across so many industries, the shock factor withers away and people are engaged in the conversation, wanting to learn more about it. There’s a couple of things you should know about industrial vibration and why it may be one of the coolest fields to work in, here’s the short list to get you started:

It’s Diverse – It’s true. Industrial vibrators can be found on the side of bins, hoppers, silos, barges

It’s Diverse – It’s true. Industrial vibrators can be found on the side of bins, hoppers, silos, barges

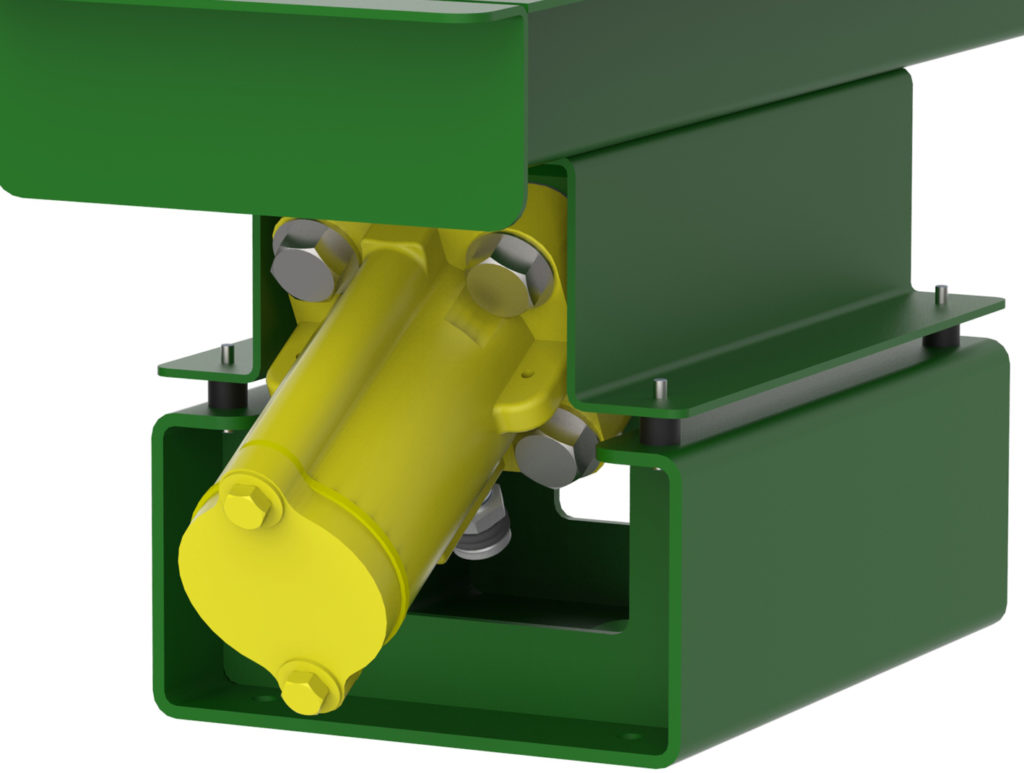

and on screening, conveying and compaction equipment. Have you passed a large dump truck lately on the highway? I’d venture to bet there may be a DC vibrator hiding away underneath the body of that truck. If you live in an area where railroad crossings are a part of your daily commute, take a second to look at the cars on those trains like the photo featured to the left… mainly the ones that have sloped bottoms where the contents empty out from. If you see a rectangular bracket hanging out on the side of the car, you can guarantee a railcar vibrator is aiding in emptying out the materials from that railcar. I swear, vibration is everywhere!

On the equipment side of the field, we have manufactured custom-built vibratory compaction tables that settle lotions and other

On the equipment side of the field, we have manufactured custom-built vibratory compaction tables that settle lotions and other

cosmetics into their product containers. Being a female, I found these pieces of equipment rather amusing. Who would have thought a major cosmetics producer would need a piece of this type of equipment in their manufacturing plant? I have also seen vibratory tables requested by Science Museums to simulate an earthquake within their exhibit. In my time at Cleveland Vibrator, I have filmed equipment designed to settle frosting evenly across chocolate cake, screen licorice and meter wheat grass seed into their grow trays. With that I say, you’re welcome for the sudden urge to grab for the nearest piece of chocolate or sugary treats that are in arms reach.

It Improves Safety – Those who work within the industry agree that raising awareness about the importance of vibration as an aid in proper safety precautions out in the field is a top tier priority. In the feed and grain industry, for instance, grain engulfment accidents can decrease exponentially if the proper use of vibration on silo walls is in place, relieving workers from having to enter the silo to rid it of ratholing and clogging. The use of industrial vibration also eliminates the need to use that heavy old sledgehammer to get rid of the hung up material within a storage container. Using a sledgehammer is not only damaging to the equipment walls, but it’s damaging to a shoulder, back or overall body of the guy delivering the blows. Save your equipment and your staff, it’s worth the investment.

It Saves You Time and Money – Did you know that applying vibration to a storage container such as a bulk bag or Gaylord can reduce your packaging cost by up to 25%? Craig Macklin posted a blog citing that applying proper vibration when packing materials in Gaylords, you could see savings well into a 5-digit number each year. Having appropriate vibratory aids throughout a process can also get rid of unnecessary production downtime, in turn saving you cash. Lastly, achieving material cleanout in truck and trailer applications eliminates costly carry backs.

It Saves You Time and Money – Did you know that applying vibration to a storage container such as a bulk bag or Gaylord can reduce your packaging cost by up to 25%? Craig Macklin posted a blog citing that applying proper vibration when packing materials in Gaylords, you could see savings well into a 5-digit number each year. Having appropriate vibratory aids throughout a process can also get rid of unnecessary production downtime, in turn saving you cash. Lastly, achieving material cleanout in truck and trailer applications eliminates costly carry backs.

It’s Global – Application of industrial vibration can be found within product processing facilities all over the world. Cleveland Vibrator has affiliations with many international distributors which provide industrial vibratory products to countries such as Canada, Japan, Australia, Israel, Singapore, Taiwan, Mexico, Chile, Spain, Honduras and India, just to name a few.

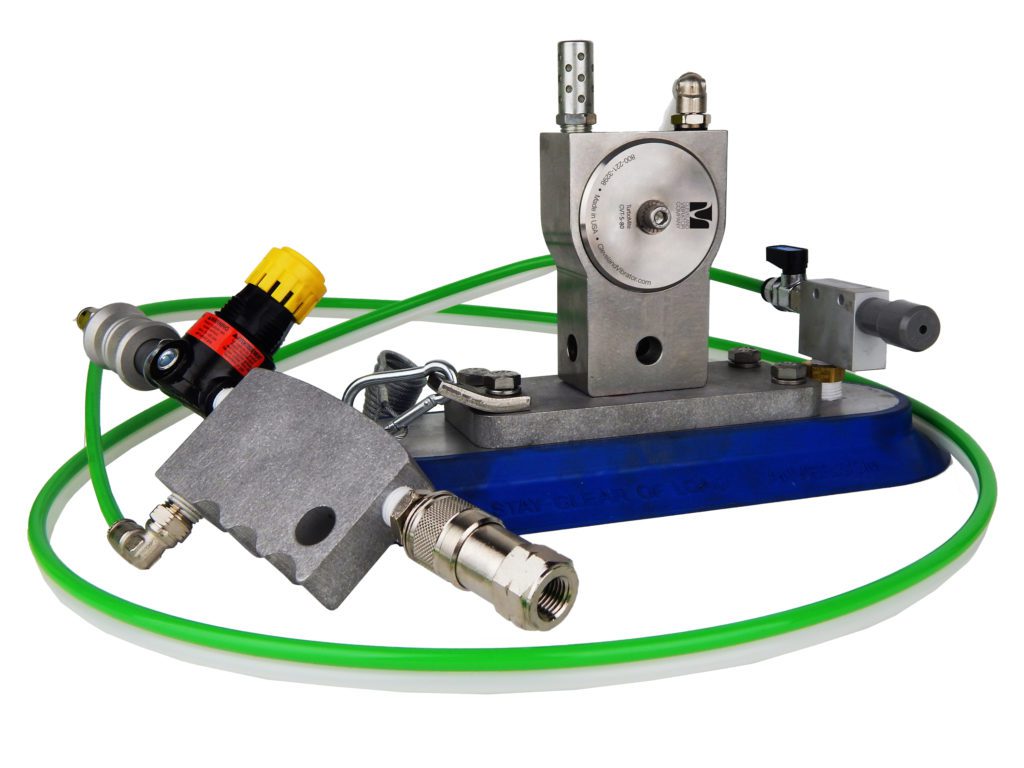

It’s Dynamic – The world of vibration is always changing, continuously improving products to fit with the customized needs of the industries it serves. For instance, the first portable vibrator debuted during the 60’s where a 1-1/2 inch piston vibrator was attached to a pistol grip handle to be used in a precast concrete manufacturing plant. Today, portable vibrators fit with suction cup mounting systems are available in the market and typically are air-operated. Units are fit with air piston vibrators usually but for applications where lighter bulk loads need removal from hoppers and bins, turbine and spring activated options are the ticket. These units provide less force and are fit with smaller suction cup mounting bases that easily fit on smaller bin or hopper walls.

It’s Dynamic – The world of vibration is always changing, continuously improving products to fit with the customized needs of the industries it serves. For instance, the first portable vibrator debuted during the 60’s where a 1-1/2 inch piston vibrator was attached to a pistol grip handle to be used in a precast concrete manufacturing plant. Today, portable vibrators fit with suction cup mounting systems are available in the market and typically are air-operated. Units are fit with air piston vibrators usually but for applications where lighter bulk loads need removal from hoppers and bins, turbine and spring activated options are the ticket. These units provide less force and are fit with smaller suction cup mounting bases that easily fit on smaller bin or hopper walls.

As I continue my quest into the deep abyss of industrial vibration, the more Vibration Education I will share with our awesome followers so stay tuned and remember to #ShakeOn!

For more information about what Cleveland Vibrator can do for you, click here to contact us!

Follow us:

Share this blog post: