Many applications of industrial vibrators are for material flow in hoppers, bins, chutes, and pipes; or material settling and de-airing. However, we frequently come across customers that don’t work with dry bulk materials or wet cast product. Instead, they are looking to apply vibration to their process to “un-stick” their wet, sticky materials from the walls of their equipment.

If we relate this to an everyday experience, picture-grabbing ice cubes from the freezer for your glass of lemonade. You get a clump of them that bonded, and they won’t fit in your glass. So, what do you do? Apply a little energy to them with some impact force (bang them on the counter) and break those bonds. Cold lemonade success!

Now, I’d like to take some time a visit a couple of the sticky applications we’ve encountered.

1) Separating bonded parts

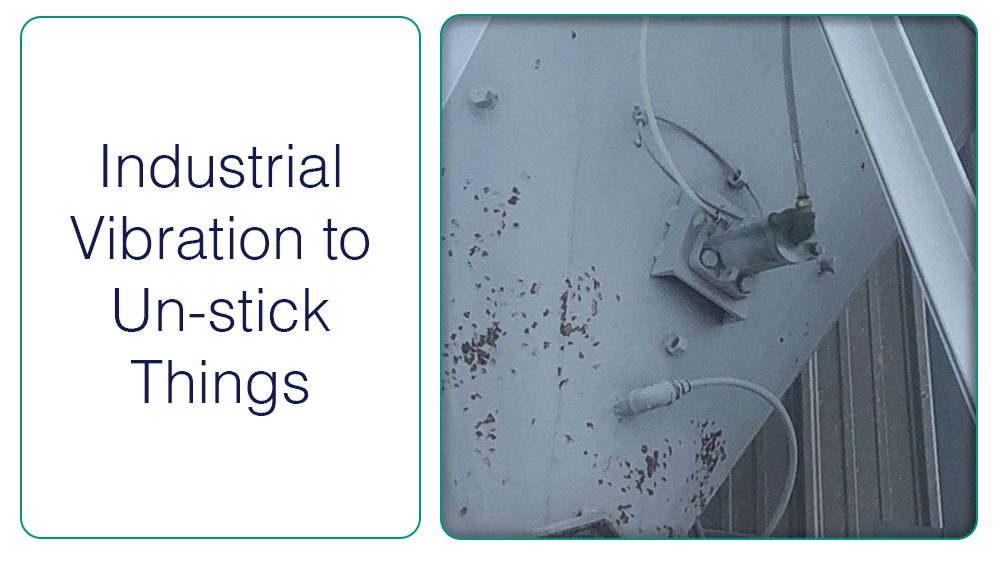

We’ve seen this type of application for parts such as hardened metal or armatures. These metal parts go through a heat-treating process and are intentionally bonded to a temporary medium during the manufacturing process. Just like the ice cube example, we have experienced success by installing a VMS Impact Piston Vibrator or SI Single Impact Air Knocker to the medium. These units apply a high-energy force to the equipment, breaking those bonds and allowing the metal parts to continue through the manufacturing process.

Learn more about the SI Single Impact Air Knocker by clicking here.

2) Getting sticky stuff off of a product

Have you ever had something gross stuck to your finger, like a freshly swatted mosquito, maybe? Your first move is to shake it off, right? Similarly, we’ve had a growing number of applications for shaking sticky, unwanted things off. An example includes vibrating air bubbles off of coated or treated parts. This allows the treatment to fully cover the product, such as in metal plating processes or shaking shot blast off/out of a treated part.

Do you have a sticky application that’s in need of some vibration? Reach out to our vibration experts! We’re happy to recommend an industrial vibrator that will keep your materials moving.

Craig Macklin joined The Cleveland Vibrator Company in 2010. Although his prior experience is mired in the world of theoretical, intangible products and services such as software and consulting sales, the past 11 years have developed his passion for this industry and molded the vibration expert we know today. Now, as President and CEO, Craig has a deep understanding of the value and importance of industrial vibration to numerous industries and applications. He enjoys fine, locally roasted espresso, good food, and spending the day with his wife and two daughters. He has cried at multiple Browns and Indians games and likes to get outside and golf in his free time.

What’s his area of expertise, you ask? “Making sure the people on our team are better and smarter than I am.” – Craig Macklin

Follow us:

Share this blog post: