I have said for years to my “better half”, you can never have enough “toys” especially as it pertains to tools and for sure in my case golf clubs. This can be said about a recent spray dryer hopper application. We normally mount one industrial vibrator to the side of a hopper or bin and sometimes two by placing the second vibrator 180 degrees apart from the first vibrator installation area. In rare cases, we will actually mount three vibrators 120 degrees apart. The spray dryer customer wanted to mount five of our 1125 SI Single Impact Air Knockers on one hopper to dislodge sticky material. Not only did they want to mount five vibrators, but they also wanted them to impact at the same time. So, the folks of Cleveland Vibrator got creative.

To be specific, we are not saying that the units would take the place of workers within your process, rather it would duplicate the motion of 5 people taking a sledgehammer to the same hopper at the same time.

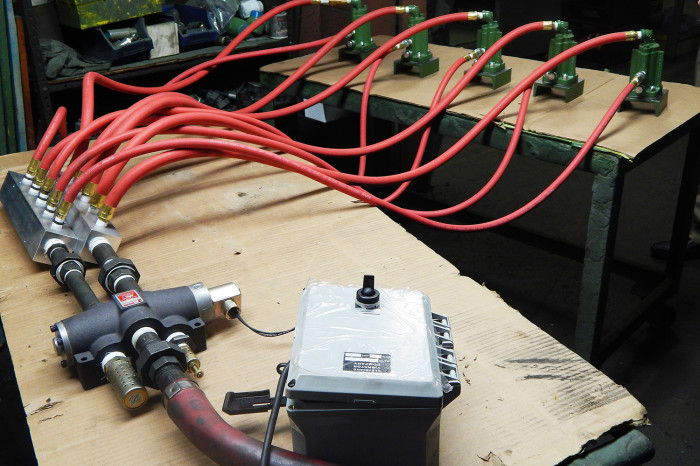

This involved oversizing the five port spool valve which delivers the air to the vibrators and also cycles the air to put the hammer back in the ready to impact position. This required the spool electrical solenoid to be controlled by a recycling time. Plus in order to supply air to the vibrators we ported the supply and return air through two manifolds. To make the installation easier for our valued customer, we assembled quick disconnects “QN” valves to one end of each hose and assembled the mating part of the “QN” to the supply and return port of the Cleveland Vibrator Single Impactors. We tested the complete assembly setup prior to finalizing for shipment and the system performed as expected. We would expect our valued customer to be very pleased with the system when installed on their spray dryer hopper. The great thing about Cleveland Vibrator Single Impactors is reducing the need for someone to strike the hopper wall with a sledge hammer or mallet that could distort or damage the hopper walls causing costly repairs. And in my opinion, even more importantly, it reduces the risk of someone being injured using a sledge hammer or mallet. Therefore making this assembly a great idea when coming up with solutions dealing with safety under consideration.

You can check out this assembly in action on our YouTube Channel! Want to learn more about this solution in motion? Contact us for information.

Follow us:

Share this blog post: