It seems to me that most applications start with a problem to solve; improve a process, simplify an operation, increase yield or throughput, or remove a bottleneck. This problem could be as simple as placing the appropriate size pneumatic piston vibrator on the side of a hopper. It could entail getting the right air-cushioned vibrator such as the 1200 VMSAC or maybe a single impacting SI vibrator along with the matching SMP mounting channel and controls. Or the problem could be broader with concerns regarding the process or task to be accomplished and the design envelope into which the solution must fit and then interface with other equipment.

Regardless of the problem, options and choices are always good.

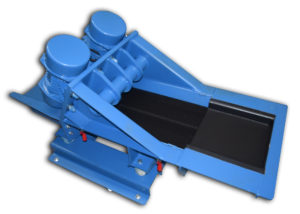

Often with equipment one of the first things that comes up in initial discussions is the design height or discharge height of the unit. With vibratory feeders (EMF) and screeners (EMS) there’s always a concern about the product discharge height, as the equipment is often feeding material downstream to other devices. One of the options that impact the design and therefore the height of the unit is the location of the vibrators. Typically on vibratory feeders and screeners, the default location is “below deck” where the vibrators are attached on the underside of the unit. With below deck vibrators, the unit will be required to have a somewhat higher discharge height to accommodate the vibrators compared to a similarly sized unit where we might “side mount” or even in some applications mount the rotary electric vibrators “above the deck.”

Functionally there isn’t a benefit locating the vibrators above, on the side, or below the unit. Provided the structure is appropriately designed for the force output of the vibrators and the vibrators “sense” each other, either vibrator location can provide satisfactory results. As I said the default location is below the unit, this makes the design of the support structure pretty easy.

So why might we want to side mount the vibrators on a screener? Two things might point us in that direction with the design:

- The customer is looking for low design height

- The customer requested an open bottom unit for the discharge of the fines

It seems pretty obvious that if we’re pushing the whole unit downward, driven by the height of the product discharge, we have to pick up that space someplace. Depending on the size of the vibrators we could actually end up saving between 12-24 inches of vertical space, by side mounting the vibrators.

Obviously, the larger the equipment the larger the vibrator, so if vertical space is at a premium, it makes sense to shift the vibrators to the side and upward. The relocation of the vibrators might give us the additional space we need to work within the customer’s design envelope. While it’s not common, we have designed and manufactured screeners with an “open bottom”. The typical electromechanical screener (EMS) is designed so that the fines, whatever passes through the screening media, are collected and discharged from the bottom of the unit via a circular outlet of some size. You can see this discharge option in the video below.

With an open bottom unit, the fines just fall away from the unit as the oversized material moves on top of the screen deck. If for instance, the customer was collecting the fines in a pile below the unit, it might be desirable to have them drop out and onto a stockpile of some sort. In that situation, the support structure and drive plate for the vibrators in a below-deck arrangement would be in the flow of material and present a problem. With side-mounted drives, the fines would essentially have an unobstructed path from the screen deck to a collection point below and outside of the boundaries of the unit.

of the screen deck. If for instance, the customer was collecting the fines in a pile below the unit, it might be desirable to have them drop out and onto a stockpile of some sort. In that situation, the support structure and drive plate for the vibrators in a below-deck arrangement would be in the flow of material and present a problem. With side-mounted drives, the fines would essentially have an unobstructed path from the screen deck to a collection point below and outside of the boundaries of the unit.

The vibrators can also be mounted “above deck” resting above the conveying surface of the unit. This configuration would result in the lowest possible unit design. I try to stay away from locating the vibrators above the deck on an EMS screener. With the vibrators above deck that area becomes a bit more congested and makes changing screen decks just a bit more fun than with the side or below deck configuration. It can be done, but there’s just more structure to deal with while removing the screen deck.

The vibrators can also be mounted “above deck” resting above the conveying surface of the unit. This configuration would result in the lowest possible unit design. I try to stay away from locating the vibrators above the deck on an EMS screener. With the vibrators above deck that area becomes a bit more congested and makes changing screen decks just a bit more fun than with the side or below deck configuration. It can be done, but there’s just more structure to deal with while removing the screen deck.

Cleveland Vibrator does make an SC-E, gravity-flow single drive screener. On that style of screener, the single vibrator is mounted above the deck and the unit is down sloped, material moves across the screen aided by vibration and gravity. On the SC-E screener, the fines are typically collected in a hopper attached to the bottom of the unit and discharged through a drop tube. With the hopper below the unit, mounting a vibrator in that area would be very difficult.

We have designed and built a number of vibratory feeders with above deck vibrators. One customer approached the company with a goal to have a very low feeder, such that they could scrap dross off the top of a ladle of molten product. Additionally, they wanted to be able to pivot the feeder over the ladle and then out of the way after loading. Interestingly, the unit was also upward sloping so that we were actually feeding the material slightly uphill. The hot dross is loaded on to the open end of the feeder and moves uphill to a circular discharge that allowed the material to drop through the unit and the turntable on which it was mounted to another vibratory feeder located below. This very low profile solution wouldn’t have been possible without mounting the vibrators above the deck.

We have designed and built a number of vibratory feeders with above deck vibrators. One customer approached the company with a goal to have a very low feeder, such that they could scrap dross off the top of a ladle of molten product. Additionally, they wanted to be able to pivot the feeder over the ladle and then out of the way after loading. Interestingly, the unit was also upward sloping so that we were actually feeding the material slightly uphill. The hot dross is loaded on to the open end of the feeder and moves uphill to a circular discharge that allowed the material to drop through the unit and the turntable on which it was mounted to another vibratory feeder located below. This very low profile solution wouldn’t have been possible without mounting the vibrators above the deck.

Cleveland Vibrator is in the business of providing solutions to bulk material handling problems. While our website and literature show standard configurations of feeders, screeners, and tables, we can tailor the piece of equipment to meet the needs of the end-user. It always works best to get our Sales Team involved with your project as early as possible so that we can explore options to provide the best solution to your unique application.

Follow us:

Share this blog post: