Here at the Cleveland Vibrator Company, we are constantly looking to help solve a customer’s problem. That problem could range from breaking up bridging material in a hopper, deblinding a screen deck, compacting dry bulk products or anything in between. Regardless of the processing line hurdle, we have the experience to assist.

Since 1923, the flagship product line for our company has been the pneumatic piston vibrator. In the 90+ years of manufacturing here in Cleveland, Ohio, a few new kids have entered the block…the vibratory material flow aids block, that is. As with any industry, applications change over time. In our world, a few that come to mind are the food and pharmaceutical projects. As our country has progressed with health standards and regulations, manufacturing facilities have had to adapt products to meet the needs for the evolving problems. The change we are going to focus on here is the elimination of lubricant, oil or grease in the air lines at processing plants.

For some operations, a frozen food packaging facility or pharmaceutical drug bottling plant for example, may require FDA compliant air tool oil or, in some cases, must avoid all types of lubricant in general. One of the most common solutions that comes to mind is often the switch to electric components and machinery. While we do agree, there are plenty of applications for rotary electric and eletromagnetic vibrators, there are some instances where other factors come in to play and the change from air to electric isn’t all that easy. Running a new power line and removing an air line are a few things that come to mind quickly. However, with the altering of requirements comes the modifications of available equipment from manufacturers.

As we touched on before, we have been manufacturing vibratory flow aids for a while. In our time, we have been lucky enough to have some great product development engineers grow our product line. In the early 2000s, our David Strong developed the turbomite pneumatic turbine vibrator. The turbine vibrators are one of a few pneumatic vibrator options we have available that can be operated without lube:

Ball Vibrators – The ball vibrators are lube free by design. The Cleveland Vibrator Econ-o-line ball vibrator is one of the original ball vibrator designs manufactured in the industry. These units operate in such a way that allows the metallic ball, located on the inside of the unit, to rotate in full 360° rotation. This movement, combined with the frequency (vibrations per minute or vpm) of the rotations and weight of the metallic ball, are the factors that lead to the force output generation.

Ball Vibrators – The ball vibrators are lube free by design. The Cleveland Vibrator Econ-o-line ball vibrator is one of the original ball vibrator designs manufactured in the industry. These units operate in such a way that allows the metallic ball, located on the inside of the unit, to rotate in full 360° rotation. This movement, combined with the frequency (vibrations per minute or vpm) of the rotations and weight of the metallic ball, are the factors that lead to the force output generation.

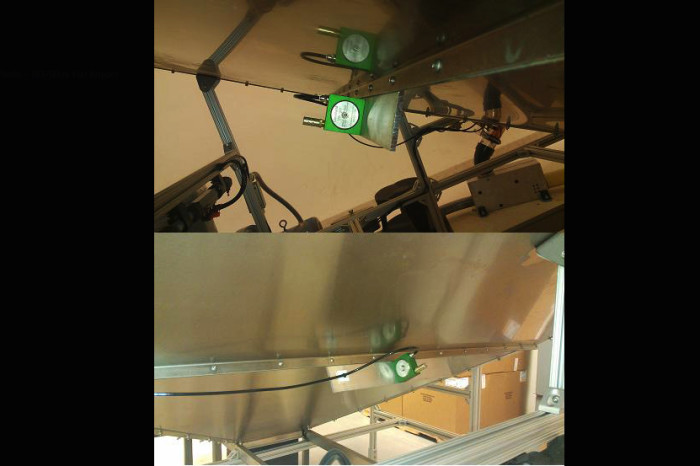

Turbomite Turbine Vibrators – The turbine vibrators are the quiet, more air efficient family member related to the ball vibrator. These units are built with a permanently greased and sealed bearing. The weighted impeller rotates, in the same 360° fashion as the ball vibrator, around the internal shaft. This offsetting weight is what generates the unbalanced factor and vibration energies.

Turbomite Turbine Vibrators – The turbine vibrators are the quiet, more air efficient family member related to the ball vibrator. These units are built with a permanently greased and sealed bearing. The weighted impeller rotates, in the same 360° fashion as the ball vibrator, around the internal shaft. This offsetting weight is what generates the unbalanced factor and vibration energies.

Coated Pneumatic Piston Vibrators – When applying the Cleveland Vibrator Super Grey (SG), a WS2 dry coating lubricant, the CoF drops dramatically. When SG is applied, the CoF is: .03 dynamic and .07 static. The lower the CoF, the easier it is for the sliding movement, thus allowing the vibrator to operate longer without the use of additional lubricant.

As you can see, there are a few ways to skin the cat. Whether you can or can’t use lubricant in your airline, we have an answer.

Our vibratory component product range is vast, always going and constantly being tested for improvements. At the end of the day, all of us here at the Cleveland Vibrator Company want to help provide a solution to your material flow problems. If there are any questions that we can help with, please feel free to contact us at any time.

Mike joined The Cleveland Vibrator Company team in 2013 with prior experience in manufacturing sales with a Cleveland company in the tool and die industry. Now, he’s the Director of Sales and specializes in “making stuff that shakes stuff”.

When he’s not immersed in the world of industrial vibration, as rare as that might be, Mike keeps busy *not finishing in last place* in Fantasy Football and enjoys spending time with his wife and three kids. It’s always golf season for Mike, and he’s been known to 3 putt his way around any course and can roll tee balls in rain or shine. You can find him tailgating in the Muni Lot before Browns games or supporting local breweries.

As an avid provider of #VibrationEducation, he offers this free bit of advice, “Not all vibration is the same. Force and frequency do matter!” However, there is a 2% upcharge for all Michigan and Steeler’s fans.

Follow us:

Share this blog post: