Back in the spring of 1996 I was finishing up work on my engineering degree, had interviewed with The Cleveland Vibrator Company and had accepted their offer of employment. My start date was in June, but first things first, I needed to finish up the degree and then get to work. Sometime after accepting the job, Glen Roberts, my future boss, had gotten the idea that it might be beneficial for me and the company for me to spend the day in Chicago walking the Bulk and Powder Show. This would give me a quick overview of the industry. I think this was the second time I’d ever attended any type of trade show and the first for me when I knew I’d be involved with the industry targeted by the show. Since then I’ve been fortunate to work a number of shows, Bulk and Powder, Foundry, World of Concrete, Interphex, NPE – Plastics showcase and the Pack Expo. The Cleveland Vibrator has products in all these industries, both equipment and individual vibrators. Again, that diversity of customers and applications is what helps keep it interesting and “entertaining” here at Cleveland Vibrator.

A couple of weeks ago I got a call from my local distributor for Firestone isolator products. We use a fair number of Airmount Isolators and Marsh Mellow Springs on our equipment. Our local guy had a regional salesman from Firestone in town and wanted to talk a bit about our use of the mounts and suggestions for product line expansion. So we ended up meeting and talking about what Firestone makes and how we apply it to our products, pretty good discussion. Almost as an aside the Firestone salesman said that occasionally they invite their OEMs to display with them at appropriate trade shows and did I think Cleveland Vibrator would be interested in displaying in the Firestone booth at a future show? Absolutely! While it’s not my decision to make, I didn’t see why in the world the company wouldn’t jump all over the opportunity. Great, maybe an appropriate opportunity might present itself in the future, seed planted.

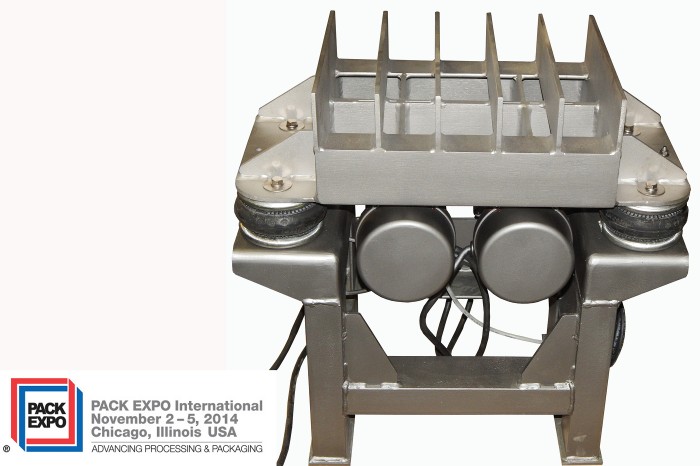

Quite surprisingly I got a call about a week later, Firestone had space in their booth at the upcoming Pack Expo and would CVC be interested? From their end, the only requirement was that our product incorporate and clearly displays a Firestone product. No problem there, certainly we have a number of products that would meet that criteria. So I kicked the call up the chain to our VP of Sales and Marketing, let the powers that be make the final decision. Well even though we have limited time to get something through manufacturing and to the show, it opens November 2nd, the decision was made to take Firestone up on the offer and display a unit! Currently Cleveland Vibrator is working to manufacture a Vibratory Grid Top Table, GT-4750 RE 24-4(2), for this year’s Pack Expo in Chicago. This is great for the company, what an exciting opportunity to display our vibratory table at a major show, one that we hadn’t planned on attending this year. The final topper for me was being asked if I was interested in working the show, are you kidding! As a person that designs products, the chance to meet with potential customers, discuss their particular applications and talk about how Cleveland Vibrator can help solve problems, attending the show is such a positive opportunity. Plus, the technology on display at the Pack Expo is outstanding, I’m sure there will be some time to walk some of the show and check out some amazing products. For me it’s a “win-win” opportunity, I’ll be like a kid in a candy shop!

So why decide to display a vibratory grid table at this show? There are a number of reasons.

Automation – If you’ve ever read Jack Steinbuch’s blog you’ll notice that he’s talked about the automation potential of a vibratory grid table when combined with either gravity roller sections or chain driven live rollers sections and even load cells. The grid table meshes well with end users who want to compact and settle products during packaging and prior to shipment. The grid table matched to an appropriate roller sections lets the customer roll product into a position above the grid table, inflate the air mounts, lift the product off the roller conveyor and begin a vibration cycle. Once compacted, the product is returned to the roller section and sent on its way. A much more fluid operation than what you might see if the same container were placed on a flat deck (FA) vibratory table manually via a tow motor or forklift. Flat deck tables and grid tops tables can produce the same frequency and intensity of vibration. Typically, any combination of rotary electric vibrators or pneumatic piston vibrators can be used on either type of table. So if we need to generate 3.5 g’s of acceleration at 1200 vibrations per minute to successfully densify the product, this can be accomplished with either vibratory table. Again the most significant difference between the two units is the grid table’s ability to stream line the flow of material through the compaction process, adding the potential for automation to this stage of a customer’s process. It makes sense to highlight this potential at a packaging show.

Flexibility – The Pack Expo seems to draw a wide range of visitors with all kinds of products and challenges. Vibratory tables, flat deck or grid top, are well suited to a wide range of applications. I’ve seen our vibratory tables used to settle and compact products that range from plastic pellets, dry breakfast cereal, fine metal powders, scrap metal, concrete in molds to railroad spikes in boxes, refractory materials, baby food jar lids, contaminated soil, cashews, peanuts, copper wire, crushed brick mixed with epoxy and even chocolate chunks. A huge range of products, all benefited from the correct application of vibration. Typically, the load requirements and in turn the g’s required are more appropriate for rotary electric vibrators plus we can select the best frequency of vibration for the product. There has been more than a few times where we did use a single or dual air piston vibrators to get the job done. In those instances we have gone with the air cushioned version of our “Vibra-Might” piston vibrator. I recall one job where I went to the customer’s location to provide some start up assistance. Cleveland Vibrator had provided a vibratory grid table using twin 1400 VMSAC vibrators; the unit generated a rather significant stroke due to the force and frequency combination of the 1400’s. The end user was compacting cashews in containers, the large stroke worked great for the cashews. The customer had a third party automating the process and they seemed to be having difficulty shutting off the fill valve at the appropriate time. I’m a big fan of cashews and it was pretty tough to help scoop up the overflow with a snow shovel and discard them! So as you can see, vibratory tables either flat deck or grid top have applications in a wide range of industries and with all kinds of products, great to showcase in front of a diverse audience such as would be attending the Pack Expo.

Visibility – As mentioned, Firestone’s only criteria for us to display in their booth was that we use their product and that their product must be clearly visible. We use both the Airmount and the Marshmellow mount as isolators on our vibratory equipment. We’ve designed and built vibratory feeders, screeners, and all of our table configurations, flat deck, grid top and belt table, using the Firestone Airmount or Marshmellow mount. The vibratory grid table is the only piece of equipment where we really can’t replace the Airmount with a Marshmellow Mount or spring. The cycle for the grid table is to roll the product into position above the table then energize a solenoid valve to inflate the airmounts. As the mounts are inflated, the grids lift the product off the rollers, once the grid table is in the “Up” position, vibration starts. The ability of the mount to inflate, raise the grid and still provide the necessary isolation is critical to the functionality of the grid table. Once the product has been compacted, we exhaust the mounts and lower the grid table to the “Down” position where the top of the grid is below the top of the roller. The compacted product is returned to the rollers where it can be moved to the next step in the customer’s process. Next to the rotary electric vibrators used on the unit, the Airmounts are the most critical element in the functioning of the table. So if we’re going to highlight a Firestone product, let’s show one that can’t really be replaced by another type isolator. With the mounts placed in the corners of the unit they’ll also be easy to see and as we cycle the table up, run the vibrators and then lower the unit, visitors will get a good view of both the table and the airmounts. The unit should be a good demonstration of the functionality of the vibratory grid table and its potential to be integrated into an automated packaging line as well as highlighting the capabilities of the Firestone Airmount.

So if your future travel plans include a stop in Chicago and you’re heading to the Pack Expo, please swing by and say “Hi”. The Firestone booth is located in the Lakeside Upper Hall, booth # 7946.

You can register for this event here.

Follow us:

Share this blog post: