The sun is shining, the ocean waves are crashing down, and I am enjoying a book on Hilton Head Island… OK. SNAP BACK TO REALITY. Living in Northeast Ohio, one could imagine our winters are long and summers fly by quicker than we can blink. Beach daydreaming is a favorite pastime of mine but also inspired me to right a little blurb about a visit made to a customer right here in Cleveland who deals with that soft every day of the year. The visit gave me a little taste of that soft sand between my toes, literally…

No, I wasn’t lounging in my beach chair, but instead hiking up on top of sand filled silos and learning all about what exactly sand is used for in day-to-day life. One of our fantastic customers invited myself and Glen Roberts to come out and see our Rotary Electric Motors in use on their chutes they use to keep bulk sand flowing through it’s heating, cooling and separating process. If you have read any of my previous blogs, you would know I am a complete sucker for history and find it fascinating to learn all about different processes and how they have evolved over time. This facility we visited was no exception. This plant has been located right off Lake Erie since the 1940’s and has original sand at the bottom of its silos since it’s opening day still present today.

Our trip was quite eye opening and once again, I was completely awestruck over the idea that such a simple material I have played in since I was a kid, played a major role in creating everyday items. We learned there are three different “grades” of sand all serving specific end product use.

- #52 Grade Sand is a coarser material and is used in foundries to manufacture metals castings. This is also the most economical grade option.

- #80 Grade Sand is super fine and we learned is typically used during the Fracking Process.

- #62 Grade Sand is a combination of Grade #52/#80 – This grade provides a better quality finish on metal castings.

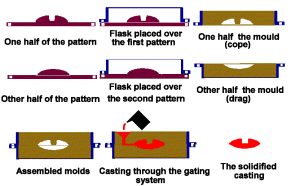

Did you know that over 70% of all metal castings are produced via sand casting process? The Grade #52/#62 Sand serves as a bonding agent during the six stage process. It’s pretty simple:

- Place your desired pattern in sand to create a mold

- Place pattern and sand in gating system

- Remove the pattern

- Fill the mold with molten metal

- Give metal cooling time

- Break the sand mold away and remove the casting and voila! You have yourself a casting!

What is “Fracking” and where does #80 Grade Sand come into play?

This falls under the category, “you learn something new every day,” for me personally. In a nutshell, it is a method used to recover gas and oil from shale rock. The hydraulic fracturing process entails drilling down into the earth and directing a high-pressure mixture of water, #80 Grade Sand and chemicals at the rock to release the gas inside. The channel is drilled vertically which allows for new pathways to collect gas or even extend existing channels.

Bottom line, what does this have to do with Industrial Vibration?

When mining the sand, the collection of materials is typically ran through a Dewatering Vibratory Screener to remove excess mud and rocky materials from the sand.

In cases like our customer, the distributor of the different grade sands, we learned that industrial vibration happens in many places throughout the sizing and prep process prior to distribution. As I said before, they utilized our RE Rotary Electric Vibrators on the chutes leading into the heating and cooling systems and they also use a 1960’s model of a Vibratory Screener to appropriately size the sand into different grades.

In cases like our customer, the distributor of the different grade sands, we learned that industrial vibration happens in many places throughout the sizing and prep process prior to distribution. As I said before, they utilized our RE Rotary Electric Vibrators on the chutes leading into the heating and cooling systems and they also use a 1960’s model of a Vibratory Screener to appropriately size the sand into different grades.

How do you think the molten metal is settled into the mold in foundries? By using Vibratory Compaction Tables, it decreases processing time by quickly and efficiently settling the castable refractory into the desired mold.

I get pretty stoked over seeing new processes and find I learn so much just by seeing how our products operate in the real world. Not only does it further my knowledge in industrial vibration, but it opens my eyes to new industries and processes I never knew existed.

Do you use Cleveland Vibrator products in your facility? We would love to see them in action, contact us today for more information. You never know, maybe your process could inspire a pretty awesome blog piece on Solutions In Motion! #ShakeOn!

Photo credit: Shale Gas Extraction – bbc.com

Sand Castings Diagram

Follow us:

Share this blog post: