When turning to a pneumatic air piston vibrator for bin cleanout or bulk material flow for your material storage vessel with a conical silo transition hopper, there are a few things we review to help determine the best unit for the job. Here are the various sets of criteria we review before making a recommendation:

- Number of vibrators needed

- Strength of vibrator needed

- Best air piston vibrator for application

Step One: Find the Number of Vibrators Needed

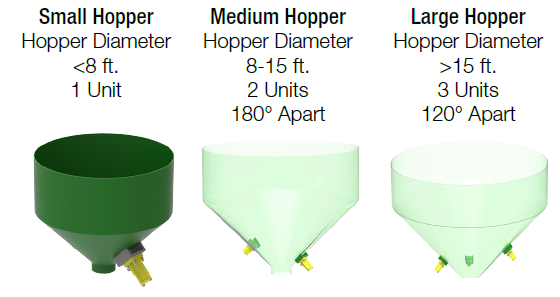

We look at the geometry of the vessel to find the number of vibrators recommended for the conical silo hopper. The vessel’s geometry, size, and shape tell us the number of vibrators needed for the most effective vibration transfer into the material. There are about 5 feet of effective radius for the vibration energy from where the vibrator is mounted. Here is a visual aid that allows you to see how many vibrators are needed based on the size of your hopper.

Step Two: Find the Strength of Vibrators Needed

Second, we look at the application and the overall goal to find the needed vibration strength. Most applications we help with fall within three categories:

- Break free sticky material from one problematic area inside the vessel

- Promote bulk material flow

- Bin cleanout

If the transition portion of the hopper is full when being vibrated, we need to take both wall thickness and total material weight in the transition hopper into consideration. This is certainly the case for bulk material flow applications and occasionally when we need to break free sticky material. To determine the total material weight, we need to know the material characteristics. This includes the bulk density, preferably in pounds per cubic foot, and moisture content.

If the goal of the vibration is to only help with bin cleanout after most material is out of the conical silo, then the wall thickness is the primary factor to consider. Without the material remaining in the hopper, we do not need to calculate the total material weight.

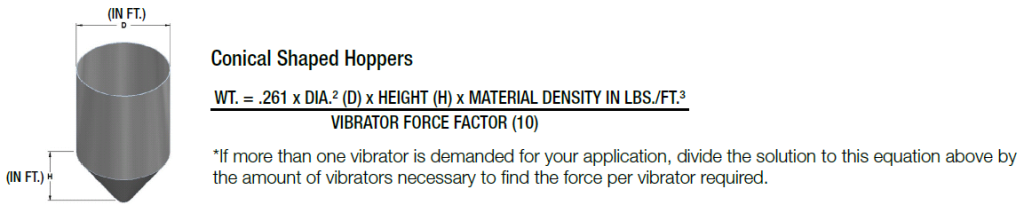

The formula we use for calculating total material weight in the transition hopper of the conical vessel is as follows:

Let’s walk through an example before moving to the next step:

- D = 12 ft

- H = 5 ft

- Material in bin = dried soybeans, approximately 50 pounds per cubic foot

- Application = promote bulk material flow

- Wall thickness = 3/16″

- WT = weight of material in transition hopper

WT = .261 x 12^2 (D) x 5 (H) x 50 (Material Density in lbs./ft.^3)

WT = total weight in hopper approximately 9396 lbs

We use the 10 lbs of material to 1 lb of force rule of thumb to get material out of a vessel. This rule of thumb is also known as the Vibrator Force Factor. With that in mind:

Total amount of force required from vibrators = 9396/10 = 939.6 lbf.

Using the information in Step One to determine the number of vibrators based on conical silos diameter, we recommend (2) vibrators. To find the proper force requirement needed per vibrator, take the amount of total force required for your application calculated above (939.6) and divide it by the number of vibrators required (2).

Pounds of force needed per vibrator = 939.6/2 = 469.8 LBF

The vibrators should be mounted on opposite sloped walls (180 degrees apart) and at staggering heights. Vibrator #1 should be mounted 1/3 of the length of the sloped wall section up from the discharge. Vibrator #2 should be 1/4 of the length of the sloped wall section up from the discharge.

Step Three: Find the Best Vibrator Needed For Your Conical Silo Application

So, we know we need about 470 LBF from each vibrator. Once we have the pounds of force required from each pneumatic piston vibrator, we look at the application details to recommend the style. A few options are available – single impact air knockers, impacting piston vibrators, or non-impacting piston vibrators. Here are the common applications for each of these air piston options:

- Single impact air knockers are best for the lone problematic areas that need sticky material “unstuck” off the inside of the vessel and bin cleanout

- Impacting piston vibrators are best for bulk flow of sticky materials (e.g. meals, DDGs, moist aggregates, etc.)

- Non-impacting piston vibrators are best for bulk flow of drier materials (e.g. corn, wheat, dried aggregates, etc.)

For this application, we would suggest the non-impacting piston vibrator to promote the bulk material flow of dried soybeans. Turning to our chart within our selection guide, we suggest (2) 1200 VMSAC non-impacting piston vibrators for this application.

If you need help with proper vibrator sizing and selection on your conical silo or would like to review our selection guide and input your specifications, please let us know. We would be glad to review the details of your application!

Mike joined The Cleveland Vibrator Company team in 2013 with prior experience in manufacturing sales with a Cleveland company in the tool and die industry. Now, he’s the Director of Sales and specializes in “making stuff that shakes stuff”.

When he’s not immersed in the world of industrial vibration, as rare as that might be, Mike keeps busy *not finishing in last place* in Fantasy Football and enjoys spending time with his wife and three kids. It’s always golf season for Mike, and he’s been known to 3 putt his way around any course and can roll tee balls in rain or shine. You can find him tailgating in the Muni Lot before Browns games or supporting local breweries.

As an avid provider of #VibrationEducation, he offers this free bit of advice, “Not all vibration is the same. Force and frequency do matter!” However, there is a 2% upcharge for all Michigan and Steeler’s fans.

Follow us:

Share this blog post: