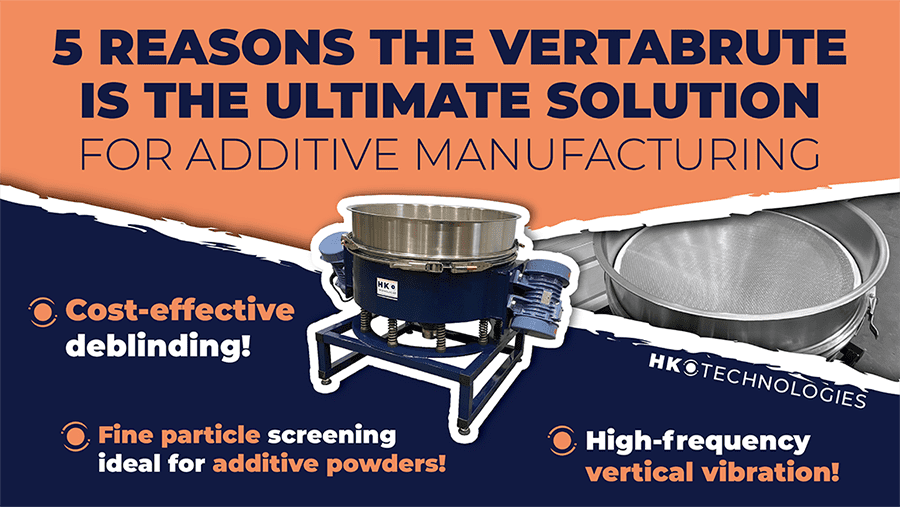

5 Reasons the VertaBrute is the Ultimate Solution for Additive Manufacturing

By Cleveland Vibrator Team

Spoiler alert: Spending money to purchase additional equipment for screen deblinding is a thing of the past. Enter the VertaBrute, HK Technologies’ all-purpose, high-energy fine mesh screener that is taking the additive manufacturing world by storm.

Here are five reasons to give the VertaBrute a closer look:

- Cost-Effective Deblinding: The VertaBrute provides ultrasonic sieving performance without having to purchase costly ultrasonic equipment.

- High-Frequency Vertical Vibration: The VertaBrute delivers effective deblinding action directly through the screen, enhancing performance with high-amplitude, low-frequency vibrations.

- Fine Particle Screening: The VertaBrute is now available in 17-inch and 36-inch screen diameters and is capable of screening down to 20 microns, which makes it ideal for additive powders.

- Durable Construction: The VertaBrute comes standard with mild steel construction and a powder coat finish making it built to last in even the harshest production conditions. Additional upgrade options using 14-gauge stainless steel in all contact areas is perfect for contamination-free environments.

- Quick Screen Changeovers: The VertaBrute is designed for rapid screen changes to minimize production downtime and maximize operational efficiency.

Explore HK Technology’s all-purpose, high-energy VertaBrute here and reach out to HK’s #PowderSiftPros to learn even more ways to elevate your screening operations.

Share this blog post: