Maintaining Proper Greasing of Rotary Electric Vibrators While Operating in the Field

By CVC Team

Being in this industry for a long time, we can relate to the uncertainty surrounding when you should grease your Rotary Electric Vibrators and how much grease you should apply. We offer an easy-to-follow installation and operation manual to our customers that discusses the specifics for each vibrator.

A section of the manual addresses proper greasing of the bearings, including when to apply the grease and how much to apply. The manual explains a ratio that takes into account the intervals vs. the actual running hours. This ratio will help determine when greasing the unit is necessary. There is, in my opinion, a “grey” area. Our Rotary Electric VIbrators need a certain amount of grease (measured in grams) to be adequately lubricated.

How do you determine the amount of grease for your rotary electric vibrator when the amount of grease per pump of the grease gun handle is unknown?

One method we’ve heard over the years is if the bearings begin to make noise, simply give each bearing five or six pumps from the grease gun and let it run for a few minutes. If this quiets the bearings after a few minutes, then you’re good to go. If not, repeat the process.

Is this recommended by The Cleveland Vibrator Company to properly lubricate the bearing? Well, no, it’s not. However, this type of greasing exists, and some swear by it. There is an old saying, “if it ain’t broke, don’t fix it,” and if it works for some folks, then we would not try to change the way they do it. However, for a straightforward approach, we looked at the amount of grease generated by one pump of a standard manual lever-operated grease gun and headed to our testing lab.

We took our standard grease gun, which uses a 14.8 ounce/420-gram cartridge, weighed out how much grease was in one pump, and then converted it to grams. We checked what the standard amount of grease would be for a grease gun of this size. The amount varied from 1.25 grams per pump to 2.25 grams, depending on how efficient your grease gun was.

A quick note that the grease we use is PREMALUBE Heavy-duty NLG1 #2 Multi-Purpose Grease H2, the manufacturer is Lubemaster. If you are working with a pneumatic vibrator, we have a blog that outlines what lubrications should NOT be used for your unit, click here to check that out.

We took many circumstances into account when performing our testing of the grease gun in our lab, such as:

- The greasing procedure is not perfect

- The effect of different operators

- Condition of the grease fittings

- Environmental temperature

- The condition of the grease gun

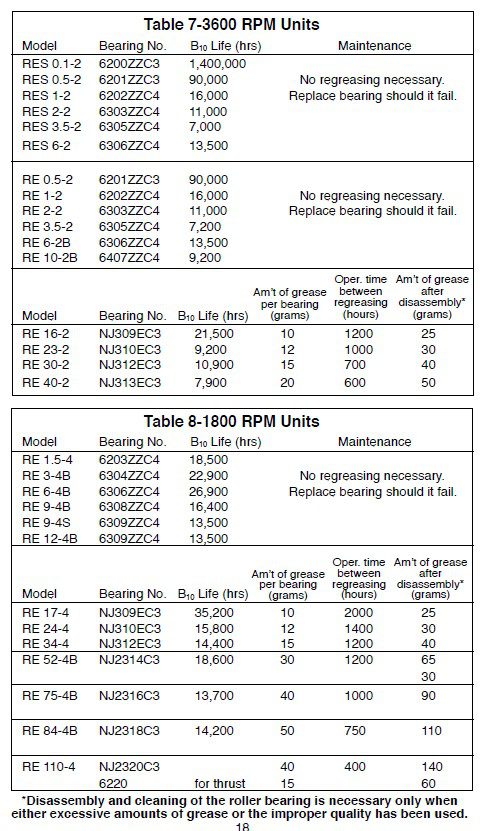

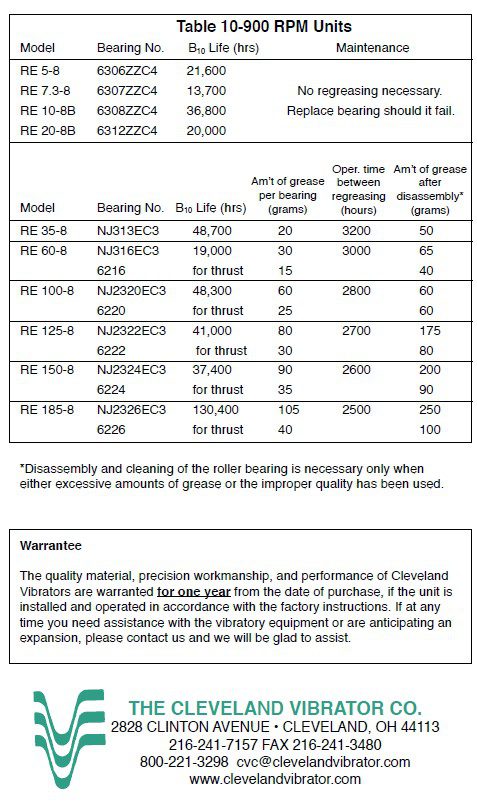

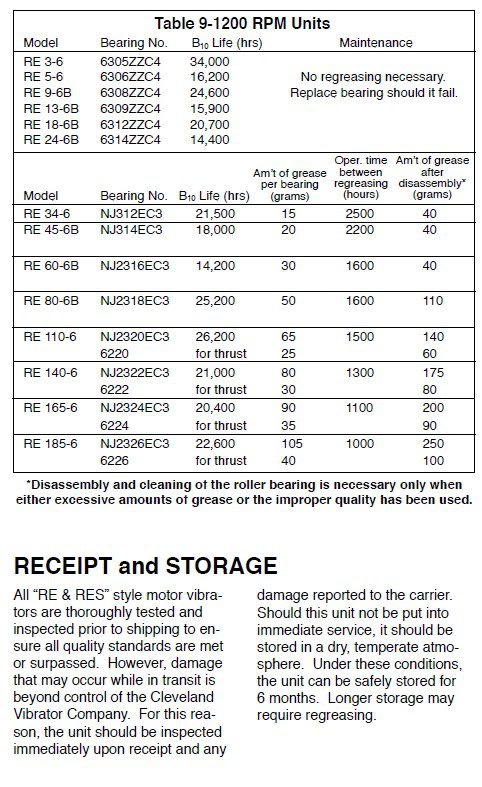

We went with 2.0 grams per pump, even with our measured weight being closer to 1.75 per pump. You can damage the bearing and cause premature failure of the unit, so it is essential to not over-grease. We concluded 2.0 grams per pump is best to prevent under-greasing as well. Refer to our RE 1200 RPM Rotary Electric Motor greasing chart illustrated below: “RE 80-6 Vibrator.” The chart indicates that adding 50 grams of grease per bearing after 1600 hrs, at 2.0 grams per pump, would be 25 pumps of the grease gun, and would add a plus or minus 10 to 20% facture to this.

You should note that you can also do half-life greasing which in the RE 80-6 case would be 12 or 13 pumps per bearing. We have included greasing charts for all RPMs below. Note that some models are permanently lubricated at the factory.

Need more information about the maintenance of your vibratory equipment? We are here to help! Click here to speak to our knowledgeable Sales & Services Team.

Share this blog post: