5 Awesome Things You Need To Know About Industrial Vibration

By Cleveland Vibrator Team

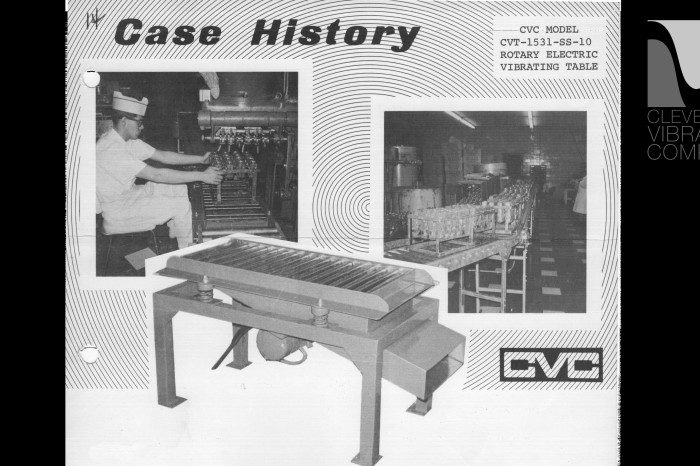

Working for the Cleveland Vibrator Company, you can imagine how many times I get the question, “what exactly do you mean by vibrators?” It’s a question I answer with great pride and enthusiasm… and maybe add a little bit of humor for good measure. When I go on to explain just how important vibration is across so many industries, the shock factor withers away and people are engaged in the conversation, wanting to learn more about it. There’s a couple of things you should know about industrial vibration and why it may be one of the coolest fields to work in, here’s the short list to get you started:

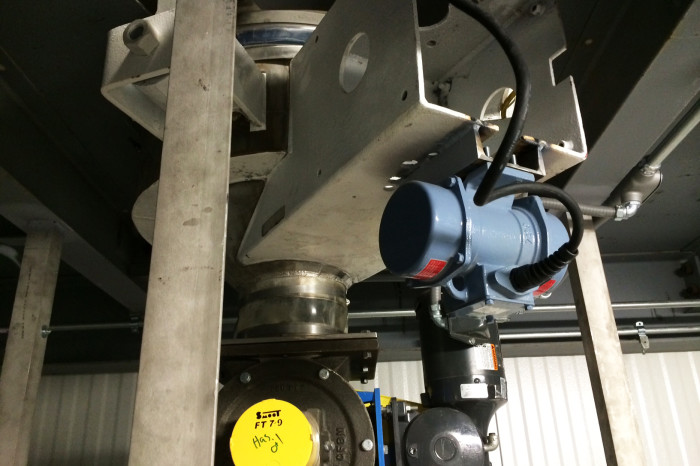

and on screening, conveying and compaction equipment. Have you passed a large dump truck lately on the highway? I’d venture to bet there may be a DC vibrator hiding away underneath the body Read More…

Share this blog post: