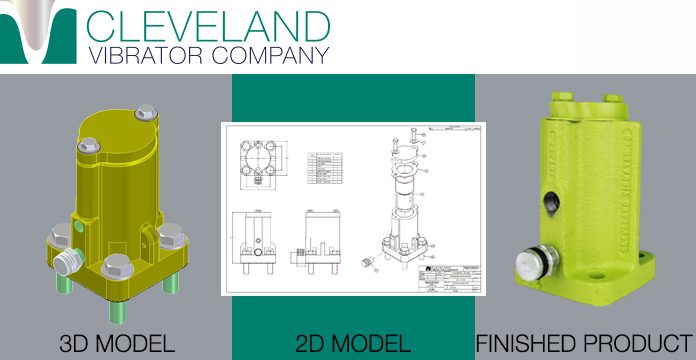

It’s a Three Dimensional World Out There

By CVC Team

A year or two ago I got an email invitation to attend a meeting of mechanical engineers sponsored by Machine Design Magazine. I guess their idea was to bring together a group of engineers to discuss the relevancy of their magazine and see where they could be more effective in reaching engineers. During the discussion, one of the engineers mentioned that his company was still working in a 2d CAD environment and they were hesitant to move to a 3d CAD package. I was more than a bit shocked. Cleveland Vibrator Company started evaluating and using 3d CAD packages back in 1998 or there about. I can’t imagine working with a 2d package after working with 3d solid models.

Our first step into the world of 3d solid modeling was with Autodesk’s Mechanical Desktop. After a couple of years of working with Mechanical Desktop we looked at changing over to Inventor, Solidworks or Solid Edge. At the time, our engineering team felt that Solid Edge had a better sheet metal package, which better supported our Fabricated Equipment product line, so we decided to go with them for our 3d solid modeling software. Since that decision, we’ve continued with the Solid Edge product and have also added one seat of their Finite Element Analysis Read More…

Share this blog post: