Tighten Those Bolts!

By Mike Stratis

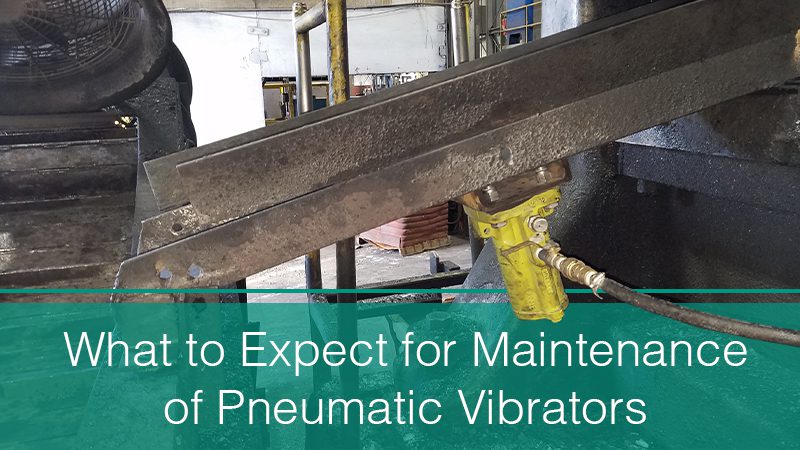

If you happened to take the time to read Craig Macklin’s blog, about the expectations for maintenance of the pneumatic vibrators, then you’ll have a good base of knowledge on how to keep those units running efficiently. This time, we’ll take a deeper dive into the importance of tightening the mounting bolts used for installing the vibrators themselves.

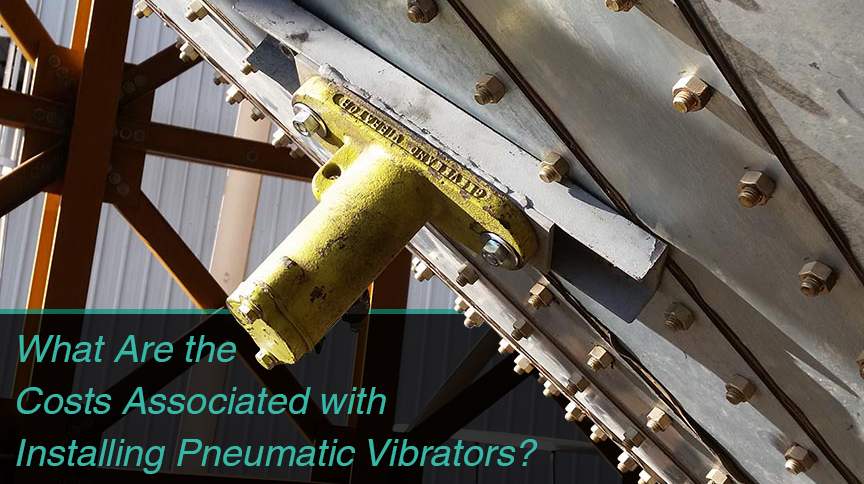

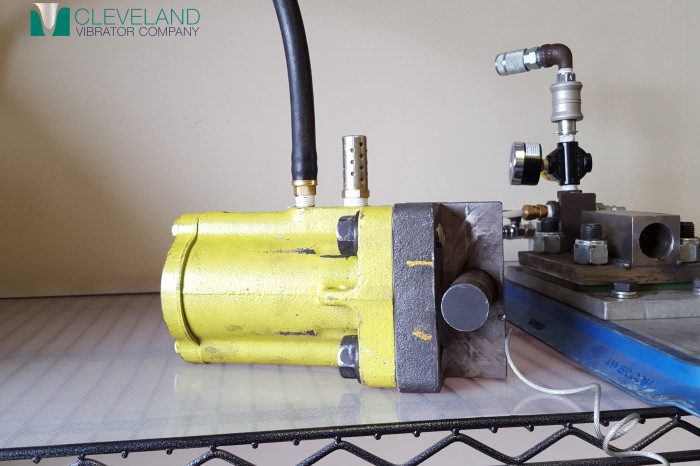

On the pneumatic piston vibrators, the proper bolt torque is critical. Because of the tight tolerance held between the outside diameter of the piston and the inside diameter of the bore of the casted body, the vibrator needs to  be rigidly bolted in place to allow for correction operation so that only the piston is moving inside the vibrator. If the bolts are loose, even slightly, the vibrator body will “rock” back and forth on the mounting channel. Once this starts happening, failures or seized pistons can happen.

be rigidly bolted in place to allow for correction operation so that only the piston is moving inside the vibrator. If the bolts are loose, even slightly, the vibrator body will “rock” back and forth on the mounting channel. Once this starts happening, failures or seized pistons can happen.

Why does this happen? The reason is, the piston will still try to move in a pure linear direction but if Read More…

Mike joined The Cleveland Vibrator Company team in 2013 with prior experience in manufacturing sales with a Cleveland company in the tool and die industry. Now, he’s the Director of Sales and specializes in “making stuff that shakes stuff”.

When he’s not immersed in the world of industrial vibration, as rare as that might be, Mike keeps busy *not finishing in last place* in Fantasy Football and enjoys spending time with his wife and three kids. It’s always golf season for Mike, and he’s been known to 3 putt his way around any course and can roll tee balls in rain or shine. You can find him tailgating in the Muni Lot before Browns games or supporting local breweries.

As an avid provider of #VibrationEducation, he offers this free bit of advice, “Not all vibration is the same. Force and frequency do matter!” However, there is a 2% upcharge for all Michigan and Steeler’s fans.

Share this blog post: