How to Operate Cleveland Vibrator’s Vacuum Mounted Series Units

By Mike Stratis

The Cleveland Vibrator Company has been manufacturing pneumatic piston vibrators since 1923. During that time, there have been a wide range of new products developed and released as the industries change. A great recent example of this innovation is the Vacuum Mount Vibrator Series.

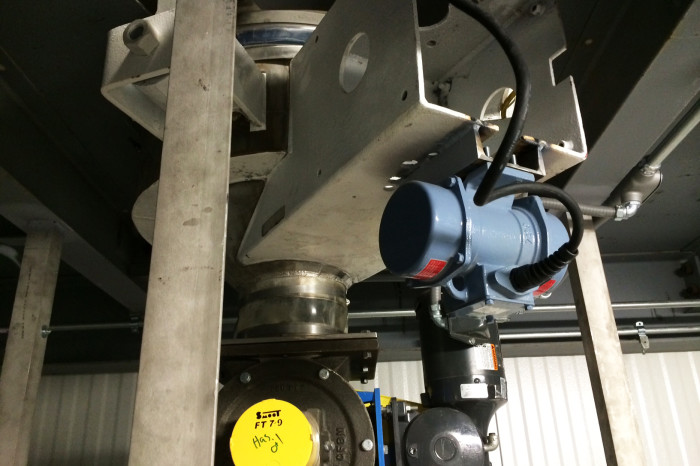

The first generation of the Vacuum Mount family was designed around the flagship product, air piston vibrators, to accommodate a wide range of applications and mounting locations. The air piston vibrators that are used are the VMSAC models, these are the non-impacting or air-cushioned piston vibrators. The reason for the non-impacting model is because the impacting model’s steel piston inside the ductile iron casted body provides a large amount of force that actually breaks the suction of the vacuum cup when installed on a bin, hopper trailer, dump bed truck, slip form or other application.

After the success of the first generation, with the VMSAC models, we expanded into the pneumatic turbine vibrators. This has allows us to provide many more options and sizes to help meet the demands of the user’s application. The original family within the product line contained four models (1125 VMSAC, Read More…

Mike joined The Cleveland Vibrator Company team in 2013 with prior experience in manufacturing sales with a Cleveland company in the tool and die industry. Now, he’s the Director of Sales and specializes in “making stuff that shakes stuff”.

When he’s not immersed in the world of industrial vibration, as rare as that might be, Mike keeps busy *not finishing in last place* in Fantasy Football and enjoys spending time with his wife and three kids. It’s always golf season for Mike, and he’s been known to 3 putt his way around any course and can roll tee balls in rain or shine. You can find him tailgating in the Muni Lot before Browns games or supporting local breweries.

As an avid provider of #VibrationEducation, he offers this free bit of advice, “Not all vibration is the same. Force and frequency do matter!” However, there is a 2% upcharge for all Michigan and Steeler’s fans.

Share this blog post: