Tough Mining Application Calls on Cleveland Vibrator Co. for a Tougher Solution

By CVC Team

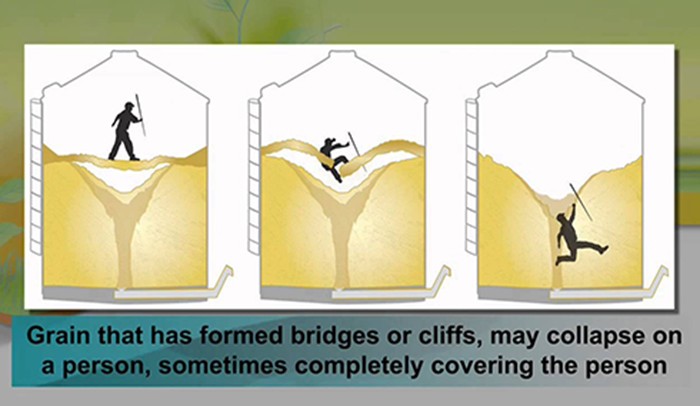

One of our strong suits has always been the ability to manufacture special vibrators for tough applications. The mining industry can be a major challenge for any air piston vibrator do to heat, extremely dusty environment and just the harshness of the application to include operating the vibrators in a 24/7 operation. The Erie Mining Company in Northern, Minnesota had such a process. They were established in 1957 for the mining of taconite ore. The process involved taking taconite, which is a hard low-grade iron ore mixed in with nonferrous rock and grinding it to separate the low grade iron ore. One of the intermediate processes is screening for further separation. This is where Cleveland Vibrator came into play. Read More…

Share this blog post: