2015: The Year of the Vibratory Table

By Cleveland Vibrator Team

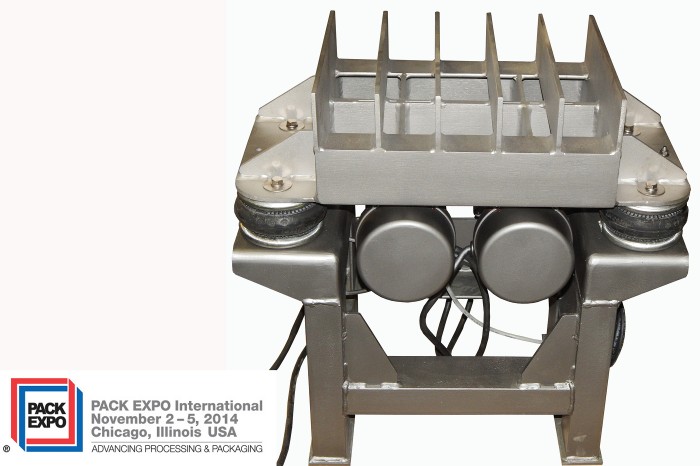

With a new exciting year in sight for me here at Cleveland Vibrator, I took some time to reminisce on some of my favorite FAB jobs that headed out of our facility throughout 2015. As I was perusing through my photo files, I found that our Vibratory Compaction Tables dominated this past year with our Vibratory Feeders running a close second. If you have read any of my other blogs, you will know that one of my favorite obligatory duties around here is filming equipment for quality assurance purposes before it leaves our manufacturing plant. Moreover, I love learning about new applications which our equipment will be used for and let me tell ya’, there were some pretty fun ones this year. So let’s take a trip down memory lane and get us stoked for the upcoming year folks!

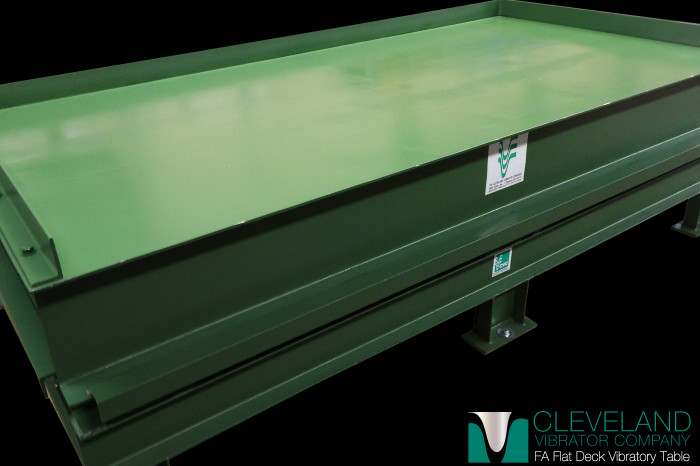

At the beginning of last year, David Strong, Jack Steinbuch and myself took a maintenance visit to a customer right here in Cleveland to see one of our flat decks in the field. Read More…

Share this blog post: