Now that we are past Memorial Day weekend, and thank you to all that have served, are serving or will serve our country, the summer months are upon us. For some, and depending where you live, these are the best parts of the year, namely, because of the warmer temperatures. While we enjoy the extra hours of sunlight and are exposed to more vitamin D, Mother Nature can have a serious effect on manmade structures. This is certainly the case for Texas and Oklahoma right now as many cities in this part of the country have experienced record rain falls for the month of May. This amount of rain can often be attributed to the rise in moisture content within the atmosphere.

So, why is this important for industrial vibration? Good question. Well, Cleveland Vibrator was founded in 1923 and over the years we have learned how differently dry bulk material can flow during various climate seasons.

In the grain and feed industries for example, the storage bins holding dried distillers grain (DDG), soymeal or something similar, can see an increased amount of ratholing and bridging of product, due to the higher humidity, preventing consistent material flow. Same for the wheat or corn bins during the sticky months prior to harvest season.

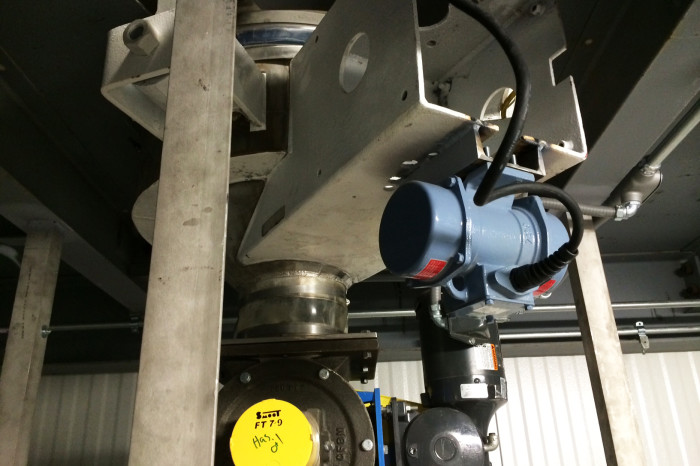

These are important factors to review when turning to a material flow aid such as a pneumatic piston vibrator, air knocker or rotary electric bin vibrator. The Cleveland Vibrator Company general rule of thumb is: any material moisture content above 10%, the next size up bin vibrator should be considered as the potential solution. The reason for this is because when there is more water in the air, the dry bulk materials often times will adhere to one another. This is drastically different than the colder or drier months where the dry bulk material particles will often times slide past each other and flow easier.

For the humid months, we do suggest stepping up a size in vibrator muscle. So, for example, if your hopper dimensions, wall thickness and material content point towards the Cleveland Vibrator 1200 VMSAC, non-impacting pneumatic piston vibrator, as the solution but it is noted that the material content contains 14% moisture then it would be wise to install the 1300 VMSAC unit to help ensure material flow. While we do understand that this would not be the case for every application, it is simply a good note to keep in the back of the head. Be sure to consult Cleveland Vibrator for further specification and details.

One might ask, well what do we do with the vibrators during those dry seasons? There are a few steps that can be taken but it depends on the unit that is installed. Here are some common problem solvers but, please note, these are only starting point suggestions. So, in order to verify, be sure to contact Cleveland Vibrator to confirm best operation method.

- Pneumatic Vibrator – regulate air pressure down 10-20psi

- Electric Vibrator – set counter weights back a few %

These settings can be checked during the operating company’s quarterly maintenance review of installed equipment. Turning back the air pressure on a pneumatic vibrator will not only help lower some energy costs but can also help extend the life of the vibrator itself. Similar things can be said in regards to lower weight % settings on the rotary electric vibrators or by dialing back the frequency if the units are controlled by a VFD (variable frequency drive). The energy cost savings might not be noticed quite like the potential savings on the air vibrators but operating the rotary electric vibrators at lower weight % settings will help extend the life of the internal bearings.

At the end of the day, all of us at Cleveland Vibrator want to help inform our customers about the different factors that can come into play when properly sizing hopper vibrators or vibratory equipment. If there are any questions that our team can answer or details we can provide, please contact us at any time.

Mike joined The Cleveland Vibrator Company team in 2013 with prior experience in manufacturing sales with a Cleveland company in the tool and die industry. Now, he’s the Director of Sales and specializes in “making stuff that shakes stuff”.

When he’s not immersed in the world of industrial vibration, as rare as that might be, Mike keeps busy *not finishing in last place* in Fantasy Football and enjoys spending time with his wife and three kids. It’s always golf season for Mike, and he’s been known to 3 putt his way around any course and can roll tee balls in rain or shine. You can find him tailgating in the Muni Lot before Browns games or supporting local breweries.

As an avid provider of #VibrationEducation, he offers this free bit of advice, “Not all vibration is the same. Force and frequency do matter!” However, there is a 2% upcharge for all Michigan and Steeler’s fans.

Follow us:

Share this blog post: