Which Industrial Vibrator Works Best for Cold Temperature Applications?

By Katy Sabo

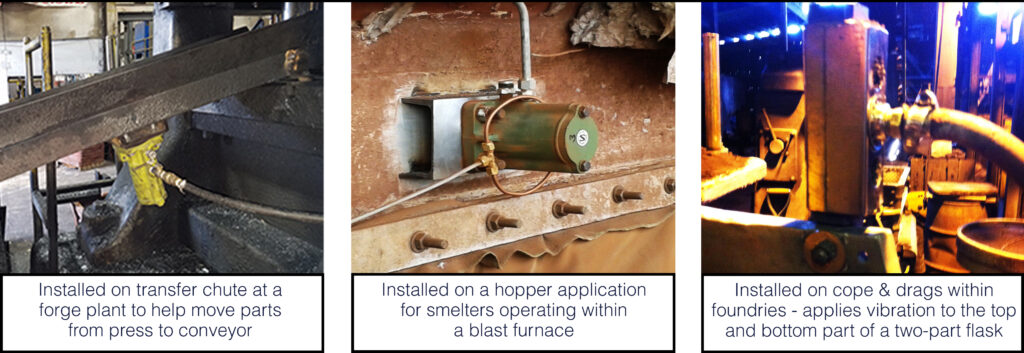

Previously, I wrote a blog about industrial vibrator options for hot temperature applications like transfer chutes in forging facilities or installations on cope & drags in a foundry. But what about those applications on the other end of the temperature spectrum?

Let’s talk about those cold environment applications like outdoor installs on a silo, chute, or load-out spout in geographic locations that face frigid temps, hopper bottom trailers delivering goods when there’s snow on the ground, or within facilities that do not have climate control.

When frigid temps are a factor, we lean towards supplying an electric vibrator option for material flow issues. Electric industrial vibrators do not require compressed airlines to operate, which is the biggest drawback when using pneumatic vibrators for these application environments.

Between RE Rotary Electric Vibrators, CM Electromagnetic Vibrators, and DC Vibrators, plenty of voltage options, force outputs, and frequencies are available.

Read More…

Katy Sabo has been the Industrial Vibrator Duchess of The Cleveland Vibrator Company since 2014. The originator of #VibrationEducation, Katy has helped create CVC brand awareness across the globe and has made it her personal priority to share the importance of Industrial Vibration with anyone willing to listen! When she isn’t shaking things up in the Marketing Department, you can usually find her shopping with her favorite sidekicks (she’s the proud mom of two little ladies), going on long walks/runs with her favorite furry family members, or rooting on any Cleveland team with her diehard fan of a husband.

Share this blog post:

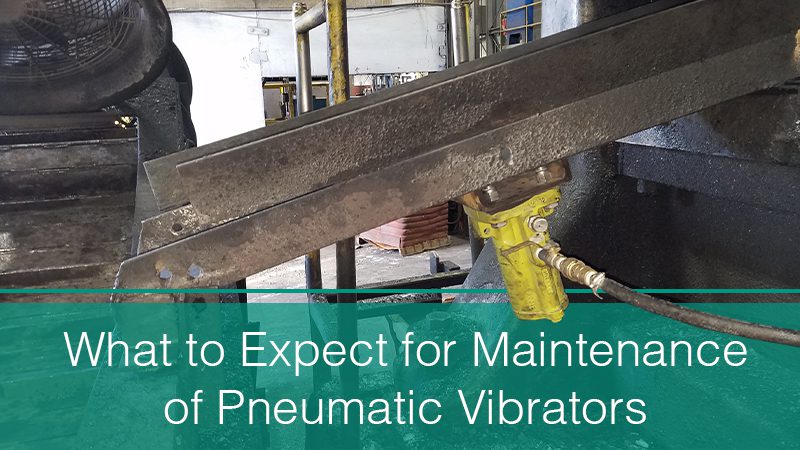

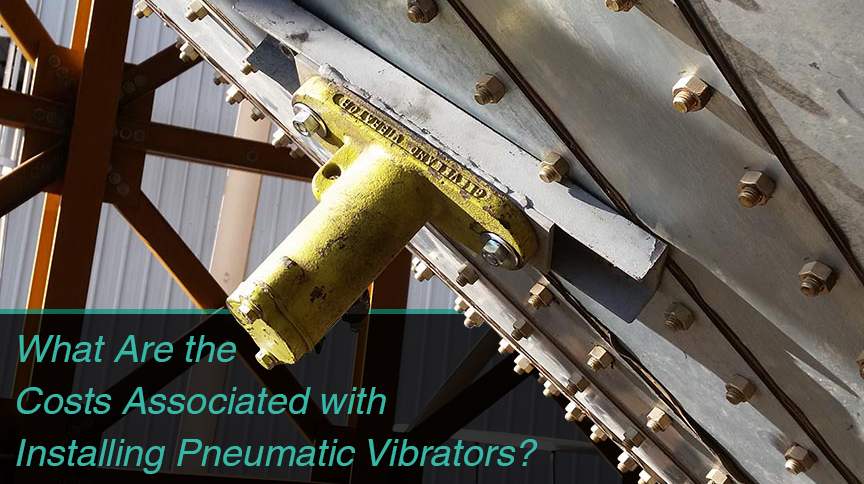

be rigidly bolted in place to allow for correction operation so that only the piston is moving inside the vibrator. If the bolts are loose, even slightly, the vibrator body will “rock” back and forth on the mounting channel. Once this starts happening, failures or seized pistons can happen.

be rigidly bolted in place to allow for correction operation so that only the piston is moving inside the vibrator. If the bolts are loose, even slightly, the vibrator body will “rock” back and forth on the mounting channel. Once this starts happening, failures or seized pistons can happen.