When it comes to terminology and lingo within the vibration industry, many times there are multiple names for the same piece of equipment. We will review what those are and explain what they mean.

Bin or hopper vibrators have many subcategories of vibrator types, just within this single product line itself. Let’s break it down.

Air vibrator or pneumatic vibrators can be the following:

- Piston type

- Ball type

- Turbine type

For the piston vibrators, there are a few common names for three different types of piston vibrators: See Figure 2 (to the right).

- Single impact

- Air knockers

- Thumpers

- Air hammers

- Traditional piston vibrator

- Impact piston

- Non-impact piston

- Air-cushioned piston

- Quiet piston

How it works: These units rely on either continuous flow of air or bursts of air for operation. The Single Impact Air Knocker (aka Thumpers, Air Hammers) requires a burst of air to impact the piston as well as a separate burst of air to return the piston back to the starting position. Whereas the traditional piston vibrators, impacting or non-impacting types, only require a single burst of air for operation. If air is applied, the piston will reciprocate back and forth to create the vibration.

For the ball vibrators, there aren’t nearly as many names in the field as the piston vibrator types. See Figure 1 (above).

- Ball vibrator

- Roller vibrator

- Rotary ball vibrator

How it works: The pneumatic ball vibrator has a steel ball inside the unit. As the steel ball spins from applied air, the spinning ball creates the off-balance action. That action is what creates the vibration.

For the turbines, similar to the ball vibrators, there are not as many names. See Figure 1 (above).

- Turbine vibrator

- Silent turbine vibrator

- Rotary air vibrator

How it works: Similar to a ball vibrator, these units have an eccentric mass that spins. However, instead of a steel ball, these units have an impeller with a weighted section. As the weighted section of the impeller spins, vibration is created.

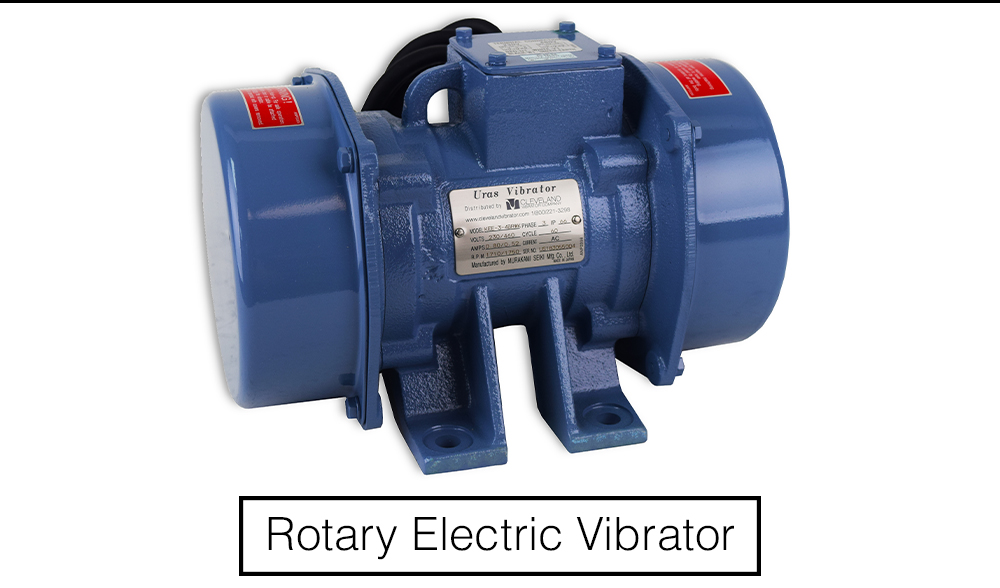

When it comes to electric vibratory motors, there are a handful of options: See Figure 3 (above).

- Rotary electric vibratory motor

- Electromechanical motor

- Vibration motor

- Shaker motor

How it works: these units are similar to the turbine vibrators, in a sense. They have counterweights that spin to create the vibration. However, these units have two counterweights, one on each end of the shaft that goes through the body of the vibration motor. As the counterweights spin, vibration is created.

Now, when it comes to vibratory machines, there are even more terms out there. There are different types of vibration equipment. Vibration feeders, machines that move material from point A to point B. Vibration tables, machines that help compact, settle, or densify material. Vibration screens, machines that help separate particles by size. Let’s dive on in.

For vibratory pan feeders, we hear: See Figure 4 (above).

- Shaker table

- Vibration feeder

- Feeder pan

- Feeder tray

- Vibratory conveyor

How it works: These machines handle material from one place to another at a specified rate. Whether that is from a hopper to a mixer or a weigh bin to a tote, the material is moving from one spot to another. The vibration is generated at an angle to the pan to help throw the material in the direction it needs to flow.

For vibratory tables, we hear: See Figure 4 (above).

- Vibration tables

- Compaction tables

- Densification tables

- Settling tables

- Consolidation tables

How it works: The vibration tables are machines that have vibration from underneath. This vibration from underneath help settle or compact materials and help consolidate or remove air bubbles from within materials.

For vibration screening machines, we hear: See Figure 4 (above).

- Sieve shaker

- Shaker screen

- Screener

- Screener/feeder

- Sifter

- Scalper

- Fines remover

- Vibration separator

- Dewatering screener

- Horizontal screener

- Inclined screen

- Desliming

- Sizing

- Oscillating

- Gyratory

- Trommel

- Grizzly

- Banana

- Mobile screen

How it works: These screening machines are similar to the pan feeders in regard to moving the materials from point A to point B and that the vibration is created at an angle to the screen deck. However, instead of a flat pan or tray as the medium holding the material while the material is moving, there is a screen deck in place. This screen deck helps separate material by size or type.

Many types of terms and often times, they mean the same thing. We’re happy to help figure out exactly what is needed for the application to solve the headaches! Reach out to our vibration experts for more information.

Mike joined The Cleveland Vibrator Company team in 2013 with prior experience in manufacturing sales with a Cleveland company in the tool and die industry. Now, he’s the Director of Sales and specializes in “making stuff that shakes stuff”.

When he’s not immersed in the world of industrial vibration, as rare as that might be, Mike keeps busy *not finishing in last place* in Fantasy Football and enjoys spending time with his wife and three kids. It’s always golf season for Mike, and he’s been known to 3 putt his way around any course and can roll tee balls in rain or shine. You can find him tailgating in the Muni Lot before Browns games or supporting local breweries.

As an avid provider of #VibrationEducation, he offers this free bit of advice, “Not all vibration is the same. Force and frequency do matter!” However, there is a 2% upcharge for all Michigan and Steeler’s fans.

Share this blog post:

Follow us: