In 1923, The Cleveland Vibrator Company began its journey in the exciting world of industrial vibration, specifically the use of pneumatic powered options for foundry applications. As we ventured into other industries, we noticed a new trend: the demand for electric-powered motors.

Soon after, we decided it was time to explore this exciting new opportunity and set out to find a partner specializing in electric-powered vibration. We eventually partnered with an outside company to supply this demand from our customer base. As with any new venture, we experienced a few hiccups along the way; lead times were too long, insufficient force options available, and the lack of “Cleveland Vibrator Quality” our customers came to expect.

Around 1980, we met our perfect match – Uras Techno. Specializing in high-quality, long-lasting Rotary Electric Vibrators, quick lead times, and a wide range of available force options, they were the peanut butter to our jelly. For the last 40 years, we have proudly offered both the CVC-built pneumatic option as well as electric options from Uras Techno. We can tailor our offerings to any application that comes our way.

Now, you may have a few questions: What are rotary electric vibrators? How do they work? Will they work with my application? You’re in luck! Below, we gathered a list of our team’s most frequently asked questions about Uras Techno and our Rotary Electric line.

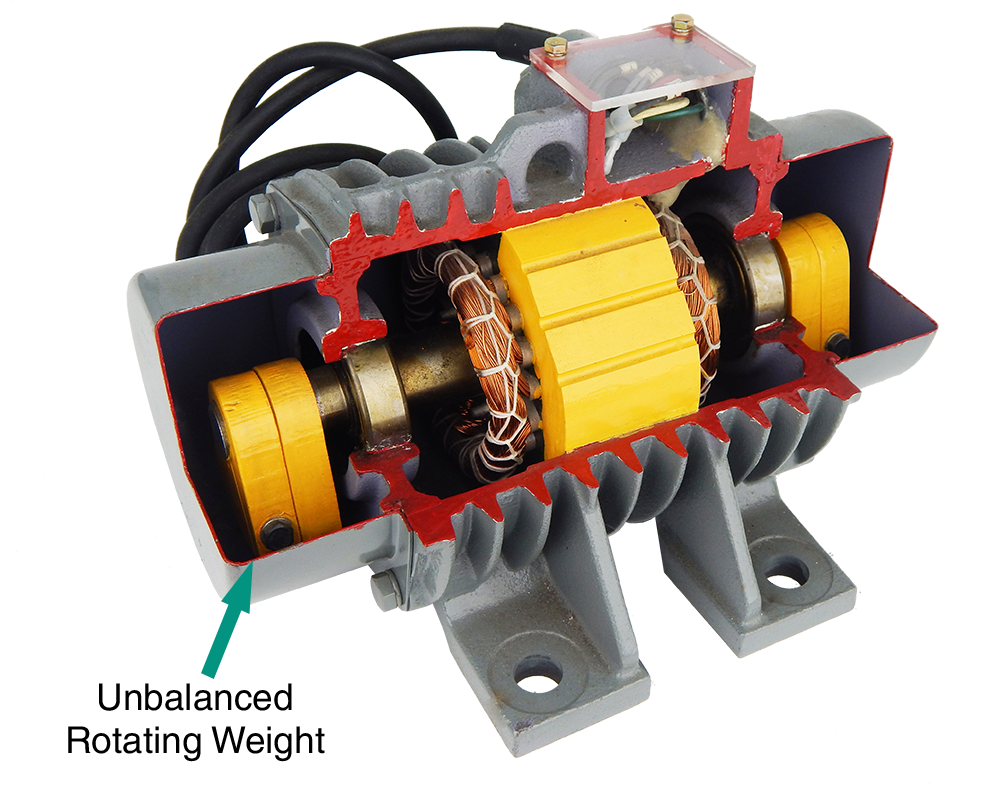

Q. What are rotary electric vibrators?

A. The concept is very simple. It is an induction motor with unbalanced weights attached to each end of the shaft.

Q. Can I adjust the force of the motor?

A. Yes! Two weights are attached to each end, a fixed weight and an adjustable weight. The force of the vibration can be set between 0 and 100% of the maximum by changing the angle of the adjustable weights. See the video below to learn more!

Q. Where are Uras Techno rotary electric vibrators built?

A. The Uras Vibrator is manufactured in Fukuoka, Japan.

Q. Is there a warranty on the rotary electric vibrators when you purchase them through The Cleveland Vibrator Company?

A. Yes! There is a 3-year warranty on all Uras Techno rotary electric vibrators. However, each motor goes through a rigorous 30-60 minute testing process before leaving Uras Techno’s facility to ensure you receive the highest quality motor available. See this process in the video below.

Q. Are Uras Techno rotary electric vibrators certified for Canadian Safety Standards?

A. All 575V units are CSA rated. CSA is also available as an option for all voltages, not only 575V.

Q. Can I change the direction of rotation of the rotary electric vibrator?

A. Single-phase motors can only rotate in the standard direction. However, you can reverse the rotation of a three-phase motor by connecting the terminals R to V, S to U, and T to W.

Q. Which direction does the shaft turn?

A. Three-phase power generally cycles between terminals in the order R, S, T. The respective power terminals are labeled U, V, and W. The Uras Vibrator’s cable has four leads: red (U), white (V), black (W), and green (ground). You can achieve the standard direction of rotation by connecting the terminals U, V, and W to the power terminals R, S, and T, respectively. In this configuration, the standard direction of the shaft’s rotation will be the same as the direction in which the cable protrudes from the terminal box.

Q. Can I change the direction of rotation on my rotary electric vibrator?

A. To achieve reverse rotation for three-phase Uras Vibrators, connect the terminals R to V, S to U, and T to W. Single-phase Uras Vibrators will only rotate in the standard direction and cannot be reversed.

Q. Can the rotary electric vibrator be installed in any orientation?

A. Yes, for non-horizontal installation, the motor has a top side and a bottom side. The top side is the side of the frame which the terminal box is on. For diagonal or vertical installation, you must orient the motor top side up.

Q. How can I generate linear vibration using rotary electrics?

A. Installing two rotary electrics with their shafts parallel and their direction of rotation opposite to each other will produce linear vibration. The vibrators will naturally synchronize with each other. See it in action in the video below.

Q. Can I change the rotational speed and vibratory force of my rotary electric vibrator?

A. Yes, you can change the rotational speed and force. You can change the rotational speed by using a variable frequency drive. The rotational force can be changed by adjusting the settings of the weights at the end of the shaft. The rotational force setting should be the same on both sides of each vibrator.

Q. In what temperature range can the Uras Techno vibrator operate?

A. The maximum recommended ambient temperature is 40°C. All units come standard with E insulation which allows for a maximum temperature rise of 75 °C above ambient temperature for a combined maximum of 115°C. Class F insulation is available and allows for a maximum temperature rise of 105°C for a combined maximum of 145°C.

Q. What is L-10 or B-10 life?

A. Bearing life is usually expressed as the number of hours an individual bearing will operate before the first evidence of metal fatigue develops. The usual life rating for industrial applications is called “L-10” or “B-10” life. Simply put, the L-10 life is the number of hours in service that 90% of bearings will survive. Or, 10% of bearings will have failed in the L-10 number of service hours.

Q. What is the typical L-10 life for the bearings in a Uras Techno rotary electric vibrator?

A. The 2-pole vibrators run at about 3,600RPM, which is very hard on the bearings. Generally speaking, 4-, 6-, and 8-pole vibrators have much longer B10 lives than 2-pole vibrators. We design the 2-pole vibrators for a minimum of 5,000 hours, calculated B10 life at 100% weight setting, and 10,000 hours for 4, 6, and 8-pole models.

Q. What is the difference between synchronous speed vs. rated speed?

A. The synchronous speed is the turning speed of the magnetic field inside the motor windings. The Uras catalog and quotations often give the synchronous speed.

The rated speed is the turning speed of the shaft and weights. The Uras Techno vibrator nameplate shows the rated speed. The rated speed is based on factory testing, but the actual speed will vary slightly based on the application and load.

The rated speed will always be less than the synchronous speed for an induction motor. The difference between the synchronous speed and the rated speed is called the “slip.”

Q. What type of grease should I use?

A. We grease the periodic-grease-type Uras Vibrators at the factory with Shell Gadus s2 v100 2. This is a lithium soap grease. When adding grease to the vibrator, it is recommended to use the same grease, Shell Gadus s2 v100 2. If this grease is unavailable, another lithium soap grease is probably the best option.

Q. How do rotary electrics differ from pneumatic industrial vibrators?

A. Pneumatic and rotary electric vibrators differ in many ways. However, the main difference is their power source. Pneumatic vibrators utilize air to power their vibration, while rotary electric vibrators use an electric power source.

Q. How much do rotary electric vibrators cost?

A. Every application is different, which means there are many different options when it comes to which rotary electric vibrator will work best for you. To provide you with the best pricing estimate, please reach out to our knowledgeable Sales & Services team. We’re here to help!

Have a question that didn’t make the list? Ask our vibration experts! Click here and let us help you keep your material moving.

Content Credit: https://www.uras-techno.co.jp/en/support/faq/

Joining The Cleveland Vibrator Company team as Sales Lead in January of 2017, Steve Chinn offers extensive knowledge and experience in the Bulk Material Handling industry. As a Cleveland State University graduate with a major in Communication and a minor in Marketing, Steve works closely with Uras Techno, the manufacturer of the high-quality Rotary Electric Motor product line exclusively distributed by The Cleveland Vibrator Company.

When not *almost* losing in our company Fantasy Football league, you can find this Cleveland sports fan golfing or spending time with his wife and two kids. He even coaches his kid’s baseball teams!

Share this blog post:

Follow us: