Industrial Vibrators and Vibratory Equipment can be used for so many different purposes that we never get bored working on customer inquiries to help them. We get to work across dozens of industries with hundreds of material types and countless unique conditions, requirements, and problems. So, it is fun to reflect on applications and problems we’ve solved near the end of a year. This posting is just that, a moment of reflection and sharing. Enjoy!!

Brewery Double Whammy –

In his very to the point song, “I Like Beer” Tom T. Hall made clear his stance on the product. I think there may be a lot of people that agree with him, too. Inquiries from breweries and distilleries certainly get some good attention from our Sales and Service Team here. Typically, we see breweries needing vibrators on their dry ingredient bins or transfers, or on their spent grain tanks. Our Air Piston Vibrators take care of that no problem. This year, we’ve seen an additional application coming through for helping maintain flow on can aligners in canning lines. I think the growing number of microbreweries is growing the number of small canning lines. Our miniature turbine vibrators have been perfect for applying just a small amount of high-frequency vibration to keep the empty cans from getting stuck in their tracks during alignment. Our wide breadth of product from miniature to enormous pneumatic vibrators made us uniquely capable to solve both problems for these breweries and keep Tom T. Hall and friends jolly.

Aluminum Advantages –

We worked on scoping a project for our GT Grid Top Table for a customer filling 50 lb boxes of a food powder. They needed to vibrate it while filling to pack and level it so it could go right to close and seal. The boxes also served as exact dose measurements for their customer’s mixing batches to make their product. The 50 lbs. had to be highly precise. Our original scope was to allow for weighing to that exact weight. Our load cell manufacturer could only guarantee precision of total weight on the scale to plus/minus a certain percentage of total weight. Our total weight on the scale would include our GT Table Top as well as the 50 lb. box of product. Thus, the lighter our top could be, the more accurate the weight reading. Designing the top out of aluminum with a focus on limiting the structural elements yielded a design that could hit the plus/minus demands of the 50 lb. box dose. While our customer decided not to move forward with the weighing on the table, the light aluminum design gave them another advantage: to meet their explosion proof environment needs, we were able to use a single, Air Cushioned Piston Vibrator rather than dual explosion-proof rated electric motors, saving thousands of dollars on cost.

Shake the Chicken Sh*t Out of It –

Of course, the materials that you would least want to have stuck to you tend to be the stickiest. Chicken Manure fits the bill there. So, when a large egg farm was looking to add a Chicken Manure pelleting facility at their farm to turn waste into fertilizer product, the engineering firm doing the design knew that they would need some vibration on the pellet mill surge bin and hammermill surge hopper to literally shake the sh*t out of them. Running through our Industrial Vibrator Sizing and Selection Guide, we got the right tools for the job to ensure production success at startup!

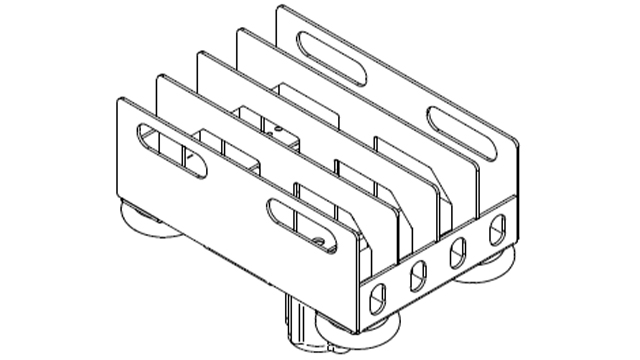

Bump the Tipped Bin Bottom –

Just like tapping the ketchup bottle when you tip it over your burger, when you tip a bin of sticky or settled material using a bin tipper, you must bang on the back of it to get everything you want out of there. For their size of bins, we sent this customer a KEE 9-4 Rotary Electric Vibrator from Uras Techno to take care of getting them a full cleanout of the bin on every tip. You can see their setup in the picture below.

Want to learn how you can use vibration for your unique application? Reach out to our vibration experts today!

Craig Macklin joined The Cleveland Vibrator Company in 2010. Although his prior experience is mired in the world of theoretical, intangible products and services such as software and consulting sales, the past 11 years have developed his passion for this industry and molded the vibration expert we know today. Now, as President and CEO, Craig has a deep understanding of the value and importance of industrial vibration to numerous industries and applications. He enjoys fine, locally roasted espresso, good food, and spending the day with his wife and two daughters. He has cried at multiple Browns and Indians games and likes to get outside and golf in his free time.

What’s his area of expertise, you ask? “Making sure the people on our team are better and smarter than I am.” – Craig Macklin

Follow us:

Share this blog post: