Here at The Cleveland Vibrator Company, we’ve committed ourselves to providing the best solution to your material flow problems for over 95 years. We like to say, sometimes “off-the-shelf” is just plain “off,” which is why our goal is to build a tailor-made solution to fit perfectly into your operation and application. Whether you need specific dimensions to fit a vibratory table into your existing process, require vibratory screen deblinding technologies, or have particular isolators you would like on your vibratory feeder; we offer design flexibility for our fabricated equipment to fit your application.

One of the many fabricated equipment customizations we offer is a selection of isolators. These mounts isolate vibration energy, which allows the feeder tray, table, or screen deck to properly vibrate instead of transferring vibration energy to your floor or structure. We generally offer four isolators for your equipment: Rubber Sandwich Isolators, Coil Springs, Marsh Mellow Mounts, and Air Mounts. Below, we will be reviewing the advantages and disadvantages of each option.

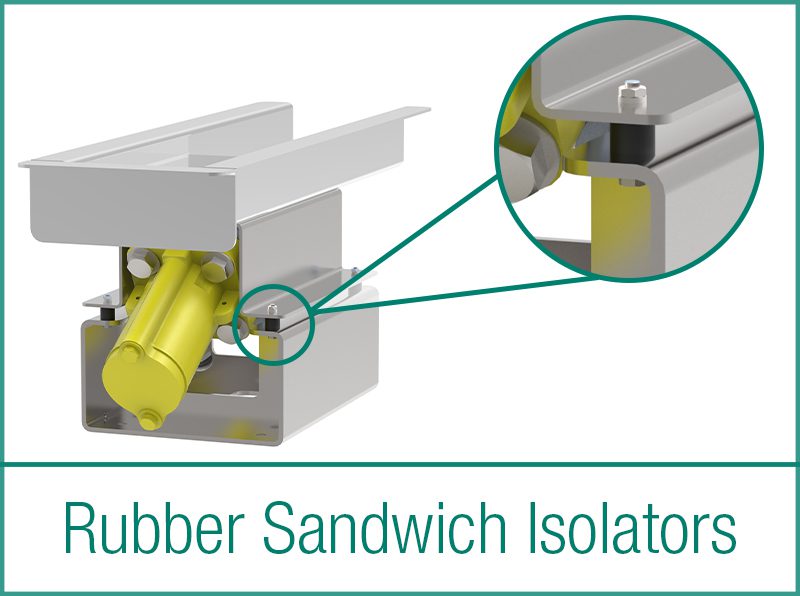

1. Rubber Sandwich Isolators – about 90% effective

Rubber Sandwich Isolators are solid, molded rubber that is “sandwiched” between either male metal threaded studs or female metal threads on both ends for mounting. They are mounted to isolate in compression or shear. Check out the photo below as an example.

Advantages

- Ideal for packers and small air-powered feeders or screeners

- Best when used in compression

- Easy to install and very economical

Disadvantages

- Not ideal for use in shear

- Do not hold up well on equipment that produces large strokes

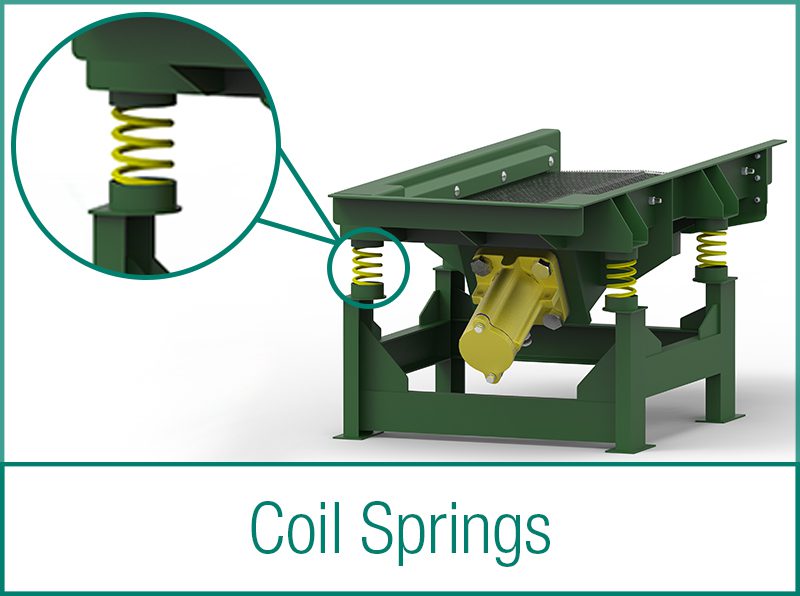

2. Coil Springs – about 85 to 90% effective

If you look at the photo below, you can see this isolator type is self-explanatory. In brief, a coil spring compresses to prevent the vibratory force from extending beyond the vibrating body. See it in action here.

Advantages

- Versatile, often used for a large majority of our applications

- Ideal for isolating cable suspended vibratory equipment

- Often used on lighter equipment where Marsh Mellow Mounts are not suitable

- Can handle shear forces produced by our feeders and screener-feeders

- Easy to install and economical

Disadvantages

- Least effective isolation

- Potentially noisy. However, it is possible to reduce the sound with urethane or rubber inserts in the spring cup holders

3. Marsh Mellow Mounts – about 90 to 95% effective

Marsh Mellow Mounts combine fabric and rubber with a solid rubber core, a hollow center, and a fabric-reinforced body. The fabric and rubber isolate reduces the vibratory force output from the vibrating body transferred to the base support. Check out an example of this isolator by looking at the illustration below or see it in action here.

Advantages

- Good to great isolation

- Can handle shear forces produced by our feeders and screener-feeders

- Easy to install

- Resilient exterior

Disadvantages

- Not compatible with high frequency

- Not available for lighter vibrating weights

- They wear inside out, so more difficult to predict when they are worn until they begin collapsing

- More costly than rubber mounts or coil springs

- Less versatile than air mounts

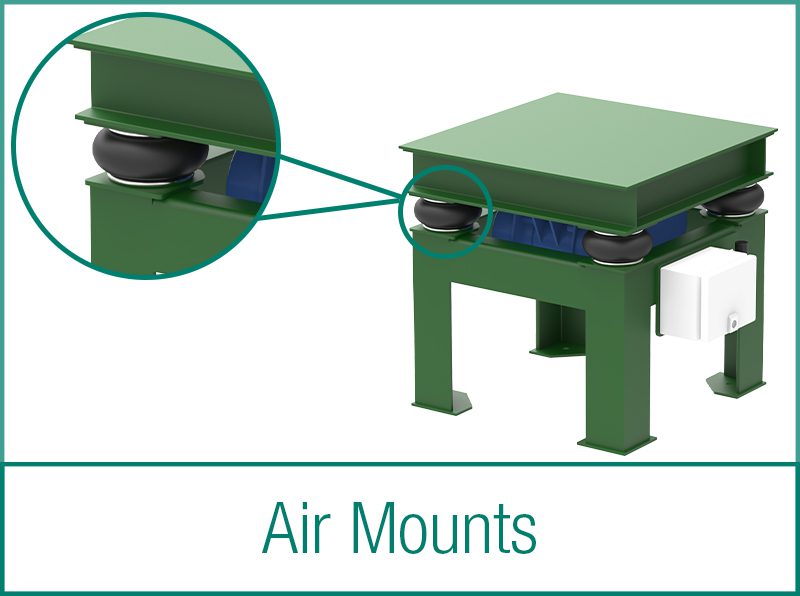

4. Air Mounts – about 95% effective

Air Mounts are inflatable rubber/fabric bellows. In detail, these isolators have an inner liner of calendered rubber: One-ply of fabric reinforced rubber, the second ply of fabric reinforced rubber with the fabric cords at a specific bias angle to the first ply, and an outer cover of calendered rubber. They isolate the vibratory force from the vibrating body when inflated with air to their design height. We program the Air Mounts into the vibratory controls package to prevent vibration from turning on when the airbags inflate as an added safety feature. See the photo below or click here to see these isolators in action.

Advantages

- Very good isolation

- Can handle shear forces produced by our feeders and screener-feeders

- Very versatile

- The only isolator that doubles as an actuator. This option is ideal for our grid tables to raise grids between rollers to pick up the container, begin the vibration cycle as grids are isolated, and then lower the container back on to roller conveyor for removal of the container when the vibration cycle is completed.

Disadvantages

- Should not be under or over-inflated – only provides optimum isolation when design height is maintained

- Can leak, cut, or burn

- More difficult to install and replace – the length of the airlines to each mount should be the same

- Requires a regulator and, in some cases, load-leveling accessories to be effective

- The most expensive isolator

Some of these options may be better suited for your build when considering your application and equipment design. For example, if you’re working with a GT Grid Top Vibratory Table, Air Mounts are required to raise the grids between rollers to pick up the load before the vibration cycle begins. To help you make the best decision, our team of vibration experts is here to help!

Contact us today to learn more about your options for customization and which isolators will work best for your application.

Jack Steinbuch has been with The Cleveland Vibrator Company for over 36 years accumulatively. He has previous experience in the manufacturing industry as a Senior Application Engineer and has worn many hats on our team in sales and managerial capacities. Now, he’s in the position of General Sales Manager. With a BSCE from The University of Toledo, he is an expert in the realm of sizing vibratory screeners and feeders, and sizing vibratory drives for tables and other vibratory equipment. Understanding that customer service is crucial, Jack believes it is important to provide the proper product for every application, even if it happens to not be supplied by The Cleveland Vibrator Company.

In his off-hours, you can find Jack spending time with his family and playing with his grandchildren. He loves sports; both watching and playing, and is an avid golfer and a league bowler during the winter. He will be retiring at the end of September 2021 and hopes to spend his winters vacationing in Florida.

Share this blog post:

Follow us: