As a manufacturer of vibratory and ultrasonic screening systems, screen wear is a huge issue for any fine mesh equipment. One frequently asked question we get from customers is, “How often should I replace my screen or mesh frame?” That can be a complicated question to answer since there are many variables to consider, including:

- What type of material are you screening?

- How often and how long do you run your screening equipment?

- What mesh are you using? i.e., How fine is the mesh or micron size?

- Are you running your screener with ultrasonics?

Why would someone need to get their frame rescreened or remeshed?

There are several common issues customers run into that require a screen replacement:

- Tears from overuse

- Too much material loaded on top of the mesh

- The product has a lot of on-size particles that will blind, clog or block your mesh openings

- Actual wire mesh wear – Over time, the wire will wear and cause your opening to increase in size, which can cause “good” material to pass through the screen.

- Hot spots or wear spots – These are caused by the incoming powder hitting the screen surface in the same location. However, this issue can be prevented by occasionally moving the screen frame, thus changing the wear spot, or using a powder diverter that will enlarge the area where the powder hits the screen.

- Physical damage

Typically, if you are running a material that is highly abrasive or angular in shape, such as glass frit, superabrasives, powder metals, or other hard or sharp materials, your mesh can wear much faster compared to a softer material, like flour. Some abrasive materials, such as powder metals used in 3D printing, are circular and sieve relatively easily. Other powder metals have a variety of powder sizes that can be either angular or have very sharp edges. These powders will typically wear or tear a screen the fastest.

Now, why are these issues detrimental to your screening process?

It’s simple. Blinding, clogging, or damaged screens can affect your material yield and even decrease the quality of your sift. Screen blinding reduces the open mesh spaces, which prevents material from passing through. If something causes physical damage or there is excess wear on the screen, you can run into issues with the spec of material you’re trying to separate.

What do we recommend for proper screen maintenance?

Here at HK Technologies, we feel the best in-house practice for our customers is to find a baseline to measure the time it takes a screen to fail or the screener performance is not at optimum throughputs. Use this measure to replace your mesh. That baseline could be in hours, days, weeks, or months.

Most importantly, do not wait until the screen fails to replace! That seems to be the customary response when we ask customers about their screen management policy. This method of screen replacement can lead to a lower quality sift and costly downtime for your process. It’s easier and more cost-effective to plan ahead and ensure your screen stays at optimal performance.

How to clean your screen:

We also recommend a good screen cleaning policy. An example of a proactive screen cleaning policy would be a customer who experiences screen blinding or wear to periodically remove the screen (possibly once a day or once a shift) and physically inspect the screen frame. This would also act as a perfect time to clean the screen mesh!

Cleaning the mesh can be done in a couple of ways:

- Use a soft nylon brush – The operator can gently brush the screen frame from the opposite side of the incoming powder. This will help dislodge lodged particles.

- Use a pressure washer – Care must be taken not to puncture your mesh, but a pressure washer can be highly effective. A lubricant, such as a dishwashing liquid such as Dawn or Lemon Joy, helps to act as a lubricant and aids in dislodging particles.

What can you do if you’re looking to replace your screen?

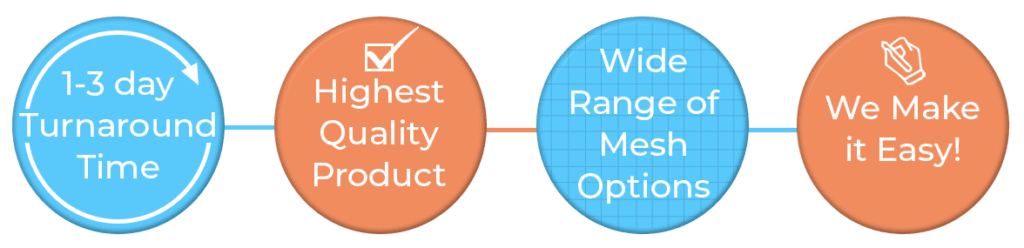

While buying new is always an option when there is excessive damage or issues with the screen frame, you can save 30-40% by opting for rescreening. We also offer a 1 – 3 day turnaround when rescreening your existing screen frame, reducing costly downtime.

Recently, we had a major powder coating equipment manufacturer who wanted to get their frames rescreened. They originally purchased their screens from an OEM who quoted them for a 6 – 8 week lead time for rescreening. After reaching out to our team, we got their frames rescreened and returned to them in just two days.

What is the process for rescreening, and what types of frames can we rescreen?

We made this process easy:

- Reach out to our team of #PowderSiftPros – You can call us at 330-427-2007, email us at sales@HKsieve.com, or reach out to our team on our website at HKsieve.com.

- Provide the needed information – We will ask for information about your screen frame diameter and mesh size. If you need more information regarding the mesh specs, we can provide histograms, an electronic measurement of the mesh openings, if required. Histograms are common for applications in the medical, food, and aerospace industries, and we are happy to accommodate them. As a note, we recommend purchasing a new frame if your screen frame is over 60 inches. This is due to the shipping cost involved in shipping larger frames.

- Send in your existing screen frame

- Our experts will rescreen your frame and have it back to you with a 1 – 3 day turnaround time

We can screen any frame from 8 – 60 inches in diameter using adhesive, solder, or spot weld frames in virtually any shape: square, paddle, round, rectangle. HK Technologies also offers an extensive selection of mesh sizes ranging from very coarse ½ – 1-inch openings to a 365 mesh (mesh size equates to the openings per linear inch) in the following materials:

- Stainless Steel

- We offer Market Grade, TBC Tensile Bolting Cloth, ASTM Wire Cloth

- Nylon

- For a more supportive option, we can use a nylon backing with stainless steel on top for extra strength

- Perforated Material

- Provides options for square or round openings

- E Form Material

- For very precise micron openings

Why choose HK Technologies for your rescreening services?

We understand it can be tempting to choose cheap wire cloth. However, we like to warn that mesh sizes can vary greatly, ranging between 10 – 15 microns! Customers have gotten wire cloth from lower-priced competitors that have been woven poorly with missing wires and wrinkles. This can lead to a lot of problems regarding the longevity of your screen and the accuracy of your material yield.

Quality control is important. That’s why we ensure your frames are easily sourced with a reliable system that guarantees quality and accuracy. By offering a fast, easy, high-quality rescreening process, you can rest assured that your frame will be returned to your exact specifications with limited downtime.

If you have any questions regarding mesh rescreening, new screens for your screener, or proper cleaning methods, please reach out to us here at HK Technologies – we would love to make your sifting operations better!

Jeff Hochadel has over 25 years of experience building and selling vibratory screening equipment. Jeff is responsible for handling fine mesh screening applications for The Cleveland Vibrator Company. His expertise is utilizing our Ultrasonic Deblinding System to solve difficult screening problems. When Jeff is not visiting customers promoting our products you can most likely find him fly fishing.

Share this blog post:

Follow us: