Great news! You decided to invest in customized fabricated vibratory equipment. Now it’s installed, working great, and you’re no longer dealing with costly, time-consuming material flow problems.

What’s next?

If you have worked with equipment in the past, you know that purchasing and installation is half of the battle. Whether you’re working with a vibratory feeder, screener, table, or any of our vibratory equipment options, maintenance is crucial to protect your investment long term. That’s why our team of experts is here to make this process easy! We compiled the list below so you know what to inspect, how often to inspect it, and what type of damage to look for when conducting regular equipment checks.

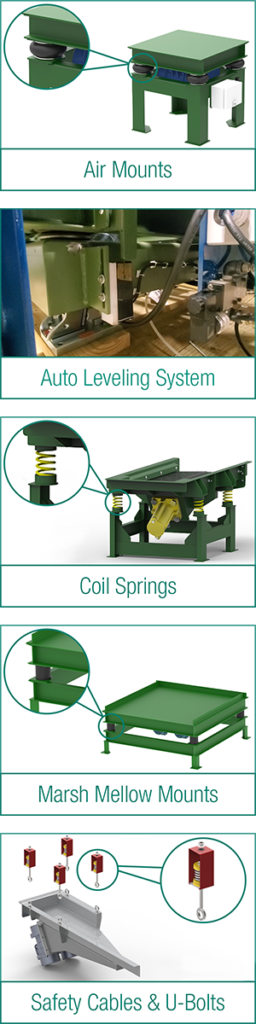

Isolator Inspections

How often to inspect: Every 6 months or after any change in process

Air Mount

- Inspect for leaks

- Check the inflated height while under load to meet air mount requirements

- If you notice damage, replace as necessary

Air mount auto-leveling sensors

- Adjust as necessary for proper air mount inflation during production run

Springs/spring hangers

- Inspect for permanent deformation/deflection due to fatigue

- Check spring cup pads for wear

- Examine hanger frames for cracks or deformation

- If you notice damage, replace as necessary

Marshmallow mounts

- Inspect for permanent deformation/deflection and wear on inside of the mounts

- If you notice damage, replace as necessary

Safety cables and U-bolts

- Make sure safety cables are in place where applicable and U-bolts holding the safety cable together are tight

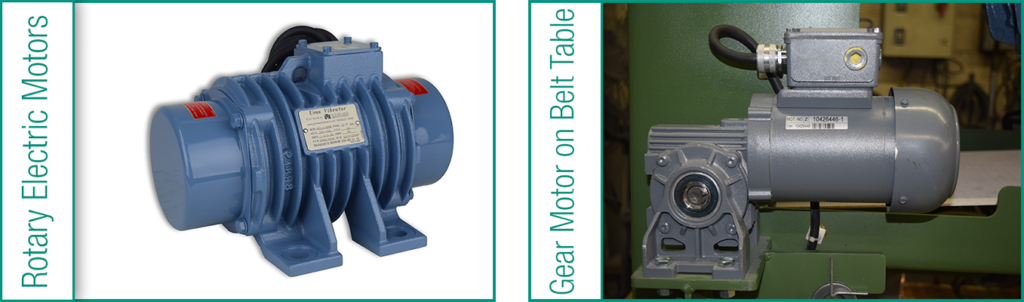

Motor Inspections for Rotary Electric or Pneumatic Vibrators

How often to inspect: Every 12 months or per manufacturer’s recommendation

Vibratory and Gear Motors

- Grease as necessary per manufacturer’s manual (If you want to learn what NOT to use when greasing your motor, click here)

Amp and temperature readings

- Take amp and temperature readings during start-up and production runs, compare to manual guidelines

- Inspect bolts to ensure they are tight

- Tighten or replace bolts, washers, and nuts as needed

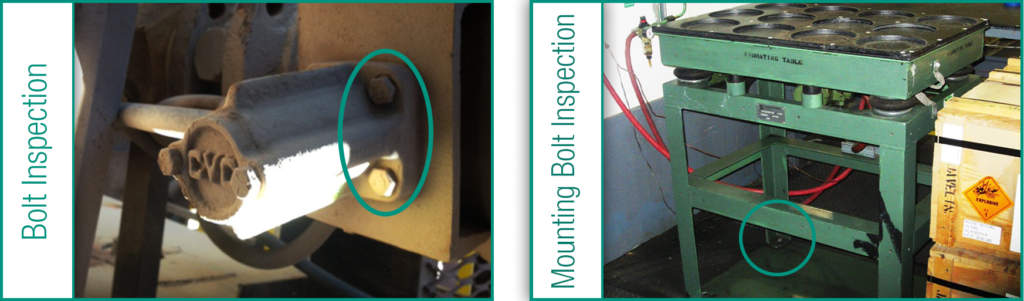

Equipment Inspections

How often to inspect: Every 6 months

- Conduct a visual inspection of welds on frame, tray, and hopper

- Send pictures of any small cracks that have formed to The Cleveland Vibrator Company

- Grind out and weld any small cracks

- Stop and contact The Cleveland Vibrator Company if welds have formed on the drive plate

Product contact surfaces

- Conduct visual inspection of product contact surfaces

- Replace liners if applicable and necessary

- Repair wear grooves or bowing damage when possible

- Adjust belt tension on belt tables as necessary

- Grease bearings used for rollers on belt tables and roller grid top tables

Mounting Bolts

- Ensure all mounting bolts holding the equipment to the floor, or other structures are tight

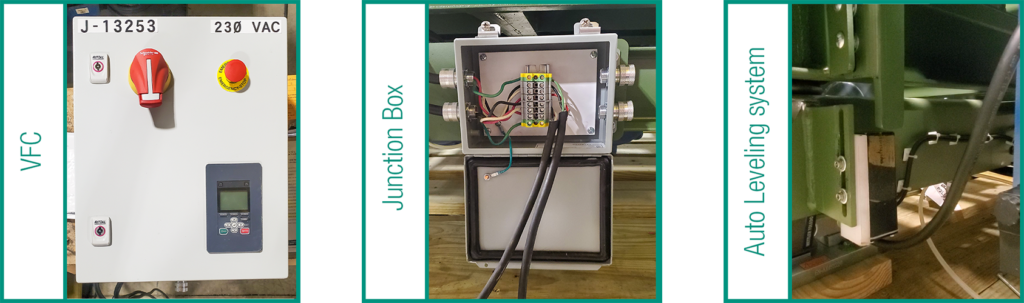

Controls Inspections

How often to inspect: Every 12 months

Wires

- Inspect all wired connections and tighten any loose wires or nuts

Junction or control boxes

- Take temperature readings of junction boxes or control boxes and review for hot spots that need to be addressed

Proper maintenance is critical to extending the life of your vibratory equipment. Reoccurring inspections and quality checks can prevent unnecessary equipment breakdowns and ensure your materials and processes stay moving, saving you time, money, and headaches in the future. If you have any questions or concerns that we didn’t address above, our team of experts is here to help.

Click here or email sales@clevelandvibrator.com to reach out to our team.

Follow us:

Share this blog post: