Hello, world! First-time blogger here, so go easy on me. If you are reading this, I’d like to say thank you. Hopefully, the next few minutes help you choose and install the optimal number of industrial vibrators for your application, and give you plenty of #vibrationeducation!

In my 7+ years with The Cleveland Vibrator Company, I’ve been lucky enough to learn from some of the most experienced in the industry. Glen Roberts has learned and thus forgotten, more than I’ll ever know about pneumatic industrial vibrators. Jack Steinbuch can size vibratory equipment in his sleep. David Strong can design anything these two toss on his desk (or in his inbox). They have more than twice my age in combined years at The Cleveland Vibrator Company between the three of them.

That’s a lot of vibrators!

However, some of the most knowledgeable conversations come from those with the customers themselves. While listening to customers, end-users and OEMs alike, one of the most common turn-offs of the externally mounted bin vibrator is the potential damage that can be done to the equipment.

Whether their lousy experience came from a poor job of vibrator sizing, mounting location suggestions, installation guidelines, improperly designed equipment structure, or anything else that led to problems, we have learned one valuable lesson:

There are times when two is better than one.

On larger hoppers, 10′ x 10′ square top, 6′ tall, 18″ x 24″ discharge with 55deg slope and 3/16″ thick exterior walls, for example, two properly sized, placed, and installed units promote better material flow. It also eliminates the chance of damaging the equipment and helps with the metering of discharged dry bulk products.

Many times, vibrators are sized based on the total weight of material inside the hopper. However, other factors are just as, and maybe more important for optimum vibrator effectiveness.

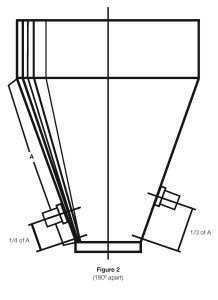

Our selection guide provides the customer with information to determine the best model, mounting location, and number of units. When the hopper is similar or larger than the above example, we recommend two smaller units staggered and mounted 180° apart. Mount the first vibrator ⅓ of the way up the sloped section from the discharge. Mount the second vibrator ¼ of the way up the sloped section from the discharge. This mounting system is illustrated below.

Stagger your vibrator during installation.

Staggering the heights of the industrial vibrators leads to differently angled vibration waves and will help transmit the energies through the product inside the hopper more efficiently. Think of it this way, if each of the vibrators are mounted at the same height while on opposite sides of the hopper, the vibration energy waves will aim right towards each other. A wise gentleman once said, “for every action, there is an equal and opposite reaction,” – Sir Isaac Newton. With the understanding of that concept, why would we want to point two vibrators directly at each other? They would work against each other.

Check out the video below to learn more:

The other general rule of thumb is, each vibrator has an approximate 5-6ft effective radius. Taking this into consideration, it is logical to incorporate a smaller dual-vibration system. Hopefully, this quick review will come in handy the next time you need help unloading the material that is either ratholing, bridging, or sticking in the corners of your storage bin.

In the meantime, if there are any immediate questions, don’t hesitate to get in touch with us! We are always glad to help.

Mike joined The Cleveland Vibrator Company team in 2013 with prior experience in manufacturing sales with a Cleveland company in the tool and die industry. Now, he’s the Director of Sales and specializes in “making stuff that shakes stuff”.

When he’s not immersed in the world of industrial vibration, as rare as that might be, Mike keeps busy *not finishing in last place* in Fantasy Football and enjoys spending time with his wife and three kids. It’s always golf season for Mike, and he’s been known to 3 putt his way around any course and can roll tee balls in rain or shine. You can find him tailgating in the Muni Lot before Browns games or supporting local breweries.

As an avid provider of #VibrationEducation, he offers this free bit of advice, “Not all vibration is the same. Force and frequency do matter!” However, there is a 2% upcharge for all Michigan and Steeler’s fans.

Follow us:

Share this blog post: