Did you know properly installing your industrial vibrator can: Ensure you get the full benefits of optimizing your material flow? Prevent unnecessary downtime and damage to your equipment? Allow you to get the most bang for your buck when it comes to your ROI?

That’s why we have multiple blogs outlining what TO do when installing your industrial vibrator. This includes my previous blog, “The Importance of Proper Installation of Industrial Vibrators” or “Vibrators Don’t Damage Equipment, Wrong Installations Do” by Craig Macklin. However, in the hopes of saving you from future headaches, we need to address a very important subject: The Top 5 Things NOT To Do When Installing an Industrial Vibrator.

1. Do not continuously weld square or rectangular mounting channels or plates to the structure.

The goal of applying vibration is to bend the wall without causing breakage or damage. Using a continuous welding technique can lead to structural damage, including breaking and cracking at the corners of the unit. Instead, we recommend stitch welding the mounting channels and reinforcement plates to the structure. Using this style of welding will distribute the vibrational force over a larger area. This will prevent cracking and damage to the equipment wall.

If continuous welds are required, which is common for applications in the food industry, the mounting plate must be round so there are no pinch points.

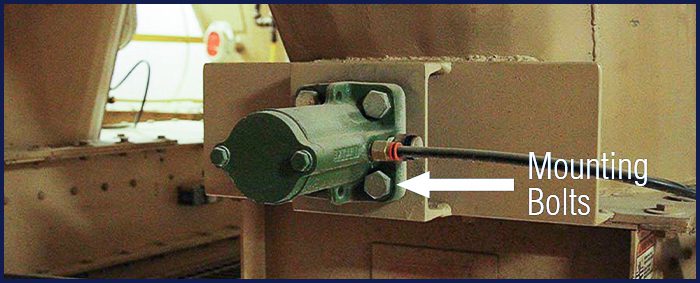

2. Do not forget to tighten the mounting bolts holding the vibrator to the channel or plate.

The industrial vibrator needs to be rigidly bolted in place so only the piston is moving inside the vibrator. Due to the tight tolerance held between the outside diameter of the piston and the inside diameter of the bore of the casted body, if the bolts are loose, even slightly, the vibrator body will “rock” back and forth on the mounting channel. Once this starts happening, failures or seized pistons can occur.

This may seem like a simple concept, but loose bolts can lead to big problems. Structural damage, improper material flow, and unit failure are all symptoms of loose bolts and can be easily avoided with regular maintenance checks. We recommend more frequent maintenance checks of the bolts the more the unit is operated.

3. Do not forget to use the proper preparation and protection when supplying air or electric power to the industrial vibrator.

If proper air preparation and protection components such as a filter, regulator, lubricator, or valve are not used to protect the pneumatic vibrator, you risk “bad” air entering the unit. This includes air with excessive moisture, dirt, dust, and contaminants which can lead to unit failure. If improper electrical components are used on the unit, an electrical surge in the power line supplying the vibrator will fry the motor.

4. Do not forget the safety cables.

In any setup, safety is vital. If the welds on the mounting channel fail, safety cables can keep the industrial vibrator from falling. This acts as an essential measure to keep employees safe and the equipment and vibratory unit damage-free. See properly installed safety cables in the photos above.

5. Last, but not least, do not be afraid to ask for help from a professional.

Selecting the correct force and frequency of vibration is critical to ensuring optimal performance and longevity of equipment. We have a selection guide that gives our customers the tools to make an informed decision about what vibration parameters to use for their application. However, to guarantee the best solution, we recommend reaching out to our vibration experts.

If you have any questions about the installation of your industrial vibrator that we didn’t cover here, our team is happy to help!

Mike joined The Cleveland Vibrator Company team in 2013 with prior experience in manufacturing sales with a Cleveland company in the tool and die industry. Now, he’s the Director of Sales and specializes in “making stuff that shakes stuff”.

When he’s not immersed in the world of industrial vibration, as rare as that might be, Mike keeps busy *not finishing in last place* in Fantasy Football and enjoys spending time with his wife and three kids. It’s always golf season for Mike, and he’s been known to 3 putt his way around any course and can roll tee balls in rain or shine. You can find him tailgating in the Muni Lot before Browns games or supporting local breweries.

As an avid provider of #VibrationEducation, he offers this free bit of advice, “Not all vibration is the same. Force and frequency do matter!” However, there is a 2% upcharge for all Michigan and Steeler’s fans.

Share this blog post:

Follow us: