Very proud father here today! This morning in the kitchen of the Macklin Family, there took place a scene featuring the current economic condition, consumer package goods, and industrial vibration, birthed by the amazing breakfast food: eggs.

I had just finished cooking and cooling a batch of hardboiled eggs (yay, protein!). My glorious-wife-whose-fantastic-shadow-I-walk-in picked one up to peel and noted, “These are small eggs.” So attuned and observant is that one.

I replied, “They indeed are. What size does the package say?”

“Large,” we found. Same as we have always bought.

Side note here:

Just a few months ago, I noticed that the Large eggs were bigger than I thought they should be, and they didn’t taste that good. Almost like somehow the same amount of flavor in a Large egg got put in an Extra Large egg and got diluted. Oddly, I thought the small Large eggs we had this morning were quite good like the flavor was concentrated. If anyone has facts on egg-making science to explain this, please don’t tell me. I might swear off eggs.

Okay, back to the story. Same Large eggs, but smaller.

My glorious wife then relates that she had just been reading about a trend of “Shrinkflation” where producers of consumer goods are battling margin pressures by shrinking the size of portions or products they are making and selling. This, of course, reminded me of some past discussion and writing I did about Slack Fill Packaging. I mentioned that practice and actually got the attention of my 13-year-old daughter. Believe it or not, she looked up from her phone and cereal bowl and wanted more explanation.

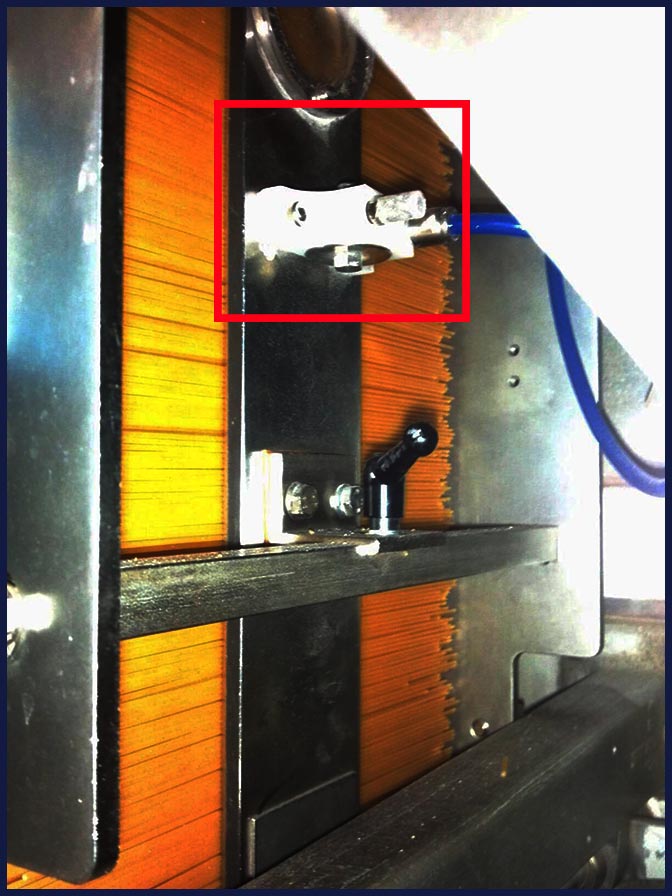

Knowing my audience’s interests, I keenly gave the example of when you open a bag of potato chips (plain Lay’s are her jam) and the bag is half full. I told her that some products, like potato chips, don’t settle perfectly when they get put in the bag. However, they do settle when they move from the packaging line to the store shelf. I’ll be darned if she didn’t instantly make the connection: “You could vibrate it!” – Truly a proud moment for this guy. As discussed in my previously mentioned blog, industrial vibration is frequently used to settle the product during packaging.

Now, those four words used up her daily allotment that she allows herself to say to her parents. So, she didn’t say this next part, but I know she thought it, Greta-Thunberg-lover-and-fellow-earth-saver that she is (this guy is also proud of that). “A lot of packaging material could be saved!”

This morning, I was inclined to follow up on my Slack Fill thoughts from 8 years ago as no discussion ever came of my previous post. Why not? As it turns out, Slack Fill lawsuits have happened but didn’t get anywhere.

This begs the question:

What is a better reason to vibrate packaged consumer products when filling, to avoid Slack Fill, or to save on packaging material and cost?

Thank you to my glorious wife, teenage daughter, and of course, eggs for inspiring thoughts and discussion this morning.

Craig Macklin joined The Cleveland Vibrator Company in 2010. Although his prior experience is mired in the world of theoretical, intangible products and services such as software and consulting sales, the past 11 years have developed his passion for this industry and molded the vibration expert we know today. Now, as President and CEO, Craig has a deep understanding of the value and importance of industrial vibration to numerous industries and applications. He enjoys fine, locally roasted espresso, good food, and spending the day with his wife and two daughters. He has cried at multiple Browns and Indians games and likes to get outside and golf in his free time.

What’s his area of expertise, you ask? “Making sure the people on our team are better and smarter than I am.” – Craig Macklin

Share this blog post:

Follow us: